Controlled Products Systems Group 107725 User Manual

Page 11

Page 11

June, 2004

750 Operator And

455 D Control Panel Installation Manual

a minimum of 5 3/4 in. (2.1 cm) long and must be as

wide as the gate leaf is thick and must fit as tightly as

possible to minimize leaf movement within the shoe

(see Figure 9).

Construct the U-shaped section of the shoe and verify

that it fits around the gate leaf. Position the U-shaped

section over the splined shaft so that the leaf's axis of

rotation will fall within the minimum dimensions shown

in Figure 10.

On the U-shaped section of the shoe, mark the position

for the leaf's axis of rotation. Next, drill a pilot hole in

the U-shaped section to mark the axis of rotation point

and mark the position for the placement of the vertical

section of the shoe.

Next you need to position the sleeve for the splined

shaft of the pinion (or the shear-pin assembly) on the

bottom side of the U-shaped section of the shoe as

shown in Figure 9. On the bottom of the U-shaped

shoe section, center the sleeve around the pilot hole

that marks the axis or rotation. Accurately centering

the pilot hole is important.

Caution: NEVER weld the splined shaft to

anything.

Spot-weld the sleeve into place on the bottom of the

shoe's U-shaped section. If you are using the shear-pin

assembly, spot weld the sleeve to the bottom of the

shear-pin assembly, and spot weld the top of the

shear-pin assembly to the bottom of the shoe’s U-

shaped section.

Next you must test the temporarily welded position of

the splined shaft's sleeve. Fit the shaft sleeve over the

splined shaft with the U-shaped section aligned in the

gate leaf's fully closed position. Verify with a plumb

line that the axis of rotation falls through the pilot

hole to the center of the splined shaft.

If the axis of rotation alignments are correct, then

permanently weld the sleeve for the splined shaft to

the bottom of the U-shaped section of the shoe.

Also, you now need to weld the pilot hole closed, and

you need to weld the vertical section of the shoe to

the U-shaped section of the shoe.

Lubricate the splined shaft with grease and place the

finished gate leaf shoe over the shaft in the closed

position.

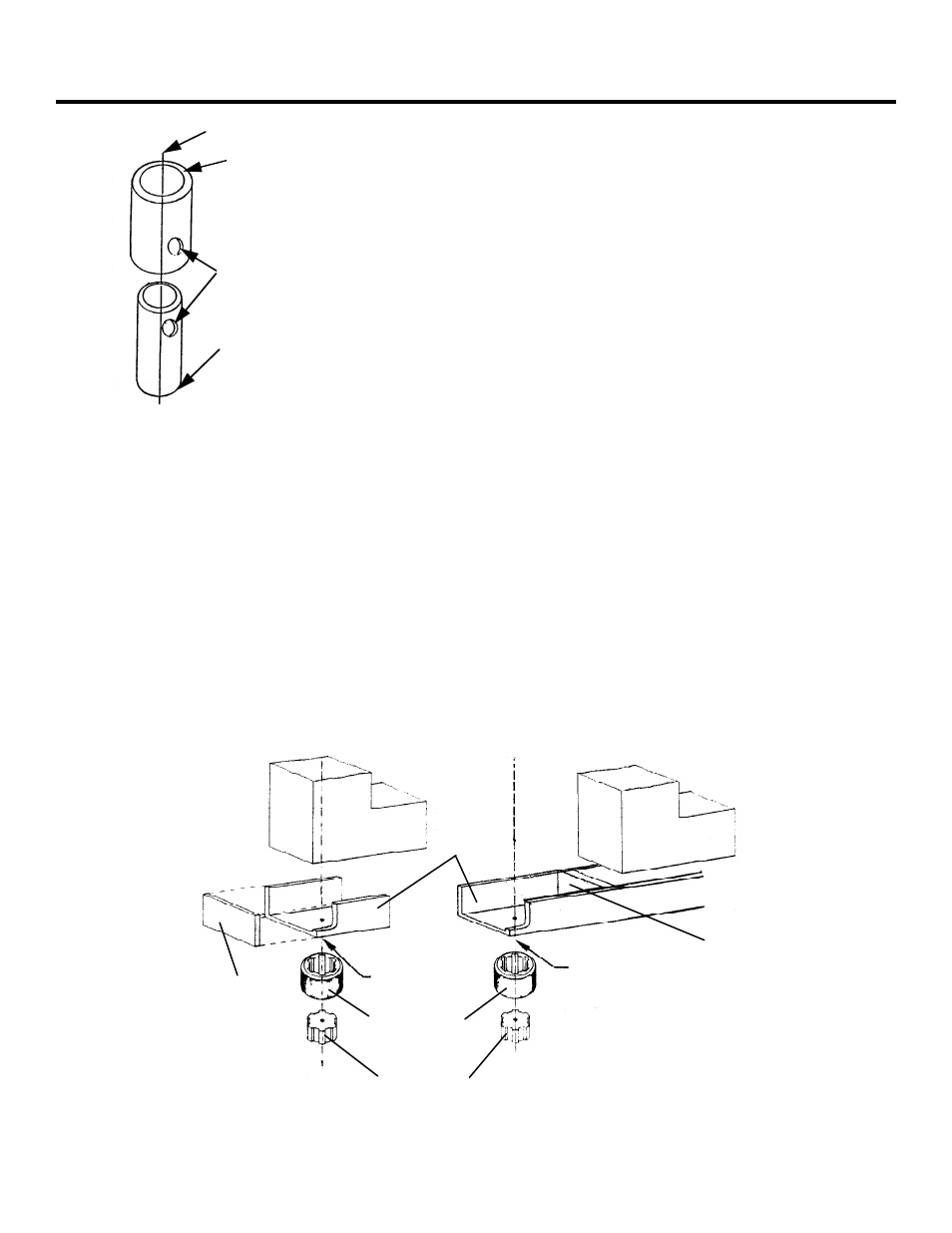

Weld this end of this pipe to

the bottom of the gate leaf

shoe, being certain you have

aligned the axes of rotation.

This 2 in. pipe (schedule 160)

has an inside diameter of 1.689 in.

Weld this end of this pipe to the

sleeve

for the splined shaft (do

not

weld anything to the splined shaft

itself). This 1 1/4 in. pipe (schedule

160) has an outside diameter of

1.660 in.

Axis of rotation of the gate leaf

Bolt or shear pin goes

through these holes and

the holes on the opposite

sides of the pipes.

Figure 8. A sample shear-pin assembly

Axis of rotation

within body of

gate leaf

Axis of rotation

outside body of

gate leaf

Splined shaft

Splined shaft

sleeve

U-shaped

section of

gate leaf

shoe

Vertical

section

Gate leaf

Gate leaf

Vertical

section

Note: The gate's axis of rotation may fall within or outside the body of the gate leaf.

Figure 9. Parts of the gate leaf shoe