455 d c – Controlled Products Systems Group 107725 User Manual

Page 12

Page 12

June, 2004

750 Operator And

455 D Control Panel Installation Manual

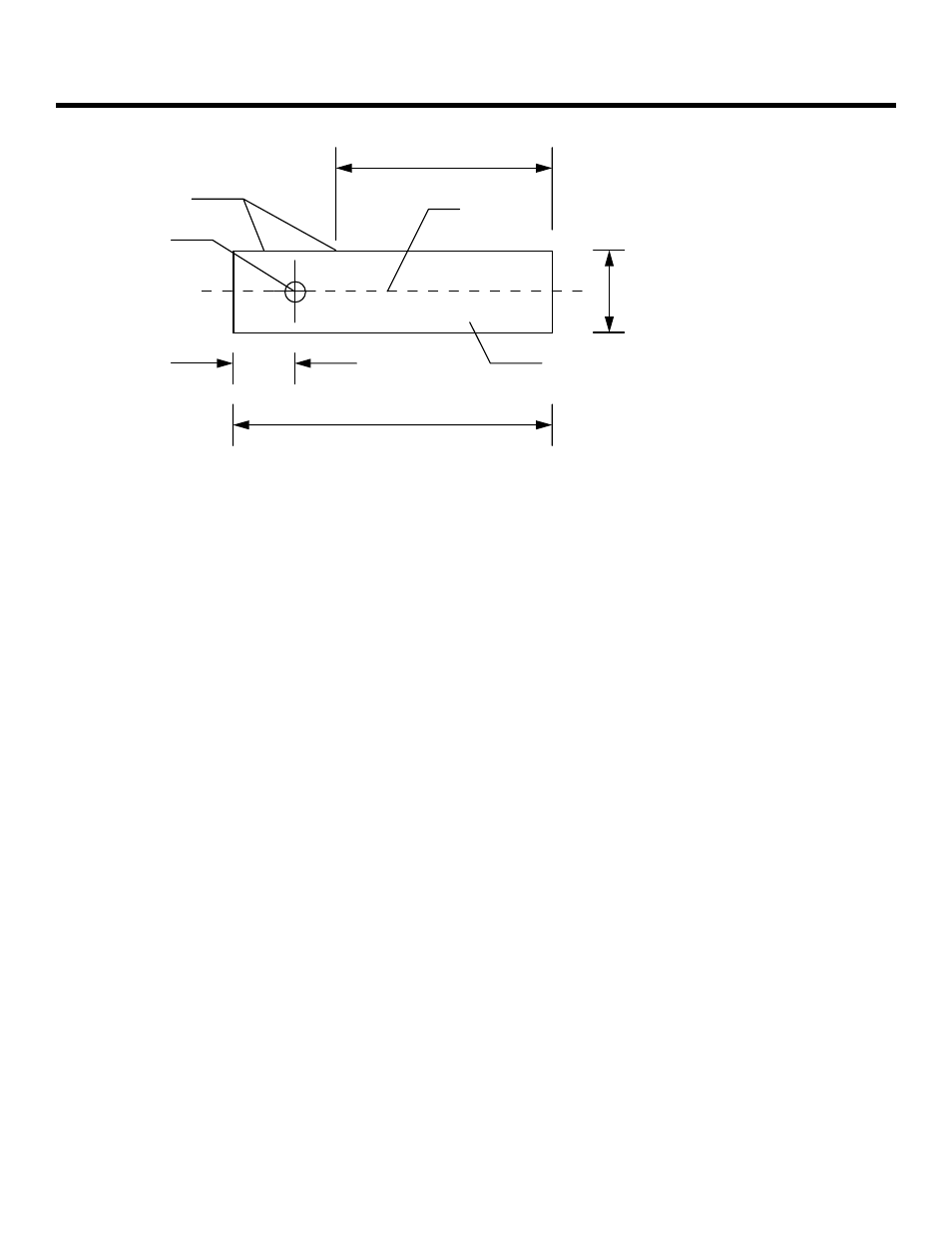

Axis of rotation

for gate leaf

Centerline of

gate leaf

Vertical section can be

located on either side

of axis of rotation

Minimum of

3/4 in. (1.9 cm)

Recommended minimum of 10 in. (25 cm)

Thickness

of the

gate leaf

Bottom of

U-shaped

section

Absolute minimum of 5 in. (12.7 cm)

between vertical section and end of

U-shaped section

Figure 10. Top view of the U-shaped

section of the gate leaf shoe.

I

NSTALL

THE

G

ATE

L

EAF

If you are not using the telescoping shear-pin assembly,

install the gate leaf by placing its 90-deg corner into the

gate leaf shoe and then installing the top gate hinge.

Installing the top gate hinge may require the gate leaf

to be at a particular height. To raise (or lower) the gate

leaf to the proper height, equally adjust the four leveling

bolts on the base of the drive unit. The bolts raise (or

lower) the splined shaft and thus the gate leaf shoe and

gate leaf.

To test the installation of the gate leaf, first make sure

that the hydraulic system has been disengaged (the

Manual Release lever should point down).

Next, very slowly open and close the gate leaf a few

times to see if it moves smoothly and evenly through its

entire path. As necessary, adjust the leveling bolts on

the base of the drive unit to correct any problems with

the gate’s travel.

I

NSTALLING

THE

455 D C

ONTROL

P

ANEL

Installing the control panel consists of the following

general steps:

•

Connecting the main power to the control

panel

•

Connecting the activating device

•

Connecting the operator to the control panel

•

Checking the direction of the motor's rotation

•

Connecting other devices to the control panel

•

Set operating modes

The installer is responsible for grounding the gate and

operator systems, for providing the main power breaker

switch, and for making sure that the entire gate system

meets all applicable electrical codes.

For the complete 455 D Control Panel Installation

Instructions, see pages 22 - 33 of this manual.

B

LEEDING

THE

H

YDRAULIC

S

YSTEM

For the 750 Operator to work smoothly, it is critical that

you bleed the hydraulic system of any air. Before you

bleed the system, be sure that you have removed the

vent screw on the top, left side of the power unit.

One bleeding operation consists of the following:

•

Running the gate leaf through three open-close

cycles

•

Allowing the gate leaf system to sit idle for

5 minutes

•

Releasing the air from each end of the drive unit

through the bleed screw holes (see Figure 1)

You need to bleed the hydraulic system before setting

the gate up for normal operation.

To run the gate leaf through an open-close cycle, make

sure the gate is set up for hydraulic operation (the

Manual Release lever is turned up) in the A mode.

Activate the gate once to open, pause, and then

automatically close. The gate needs to open and close

three times.

Then you need to allow the gate to sit idle for a full five

minutes. During this time, you can disengage the

hydraulic system (turn the Manual Release lever down)

and make sure that the top cover is removed from the

drive unit to allow you access to the bleed screws on

either end of the unit.