Aintenance, 750 o, 455 d c – Controlled Products Systems Group 107725 User Manual

Page 34

T

HE

750 O

PERATOR

The FAAC recommended maintenance schedule varies

according to the frequency of use of the operators,

whether lightly used operators (once or twice an hour)

or heavily used operators (many cycles per hour).

Check the oil.

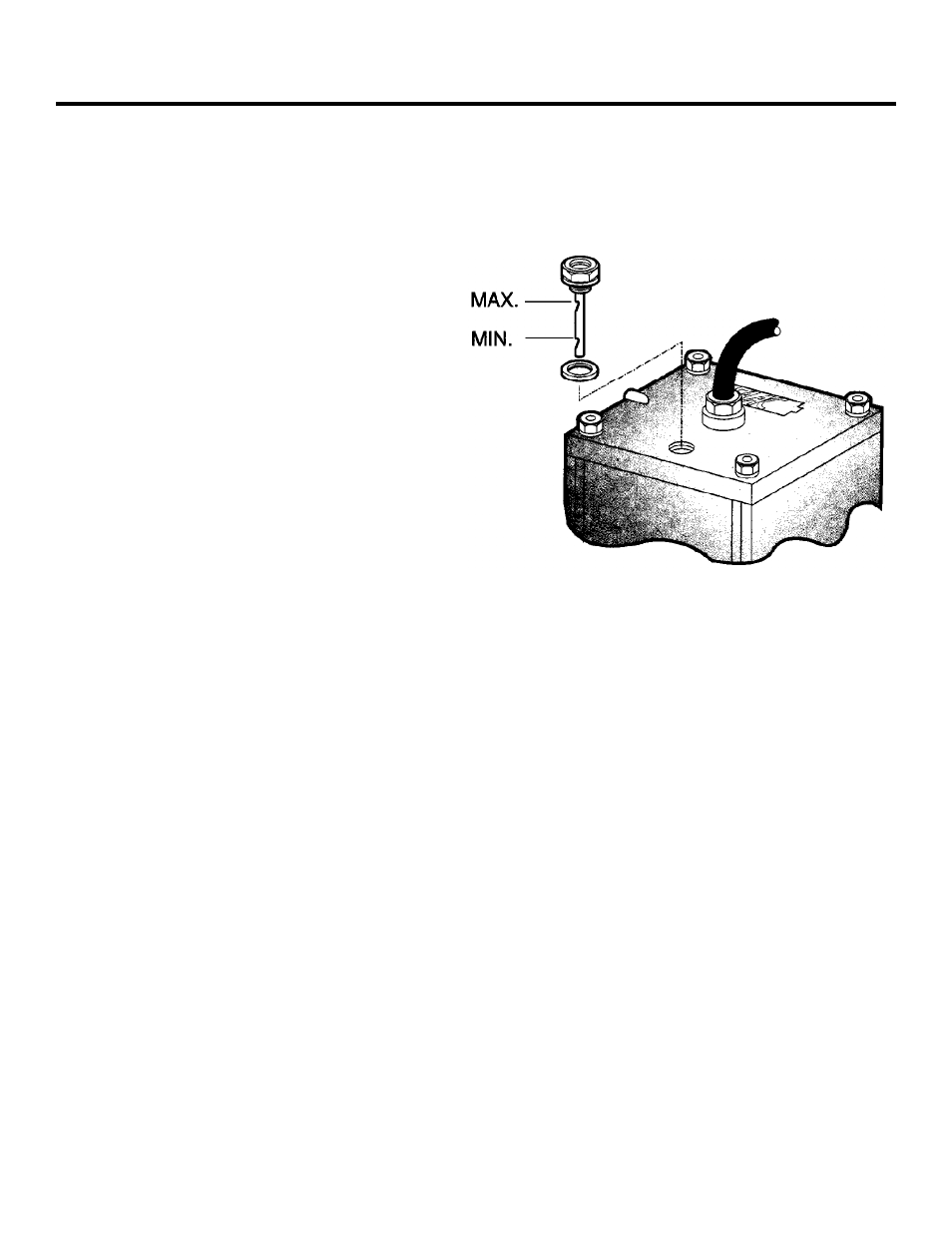

To check the oil level correctly, remove the oil filler

cap on the top of the power unit. A dip stick is

attached to the bottom of the cap for checking the oil

level as shown in Figure 14.

Light duty use: check once per year

Heavy duty use: check every 6 mo

Change the oil.

Changing the oil completely in the hydraulic system

of the 750 Operator requires removing the power unit

and drive unit from their installed positions unless

you are able to pump the oil out of both units.

Light duty use: change every 4 yr

Heavy duty use: change every 2 yr

Check the pressure settings.

Light duty use: check once per year

Heavy duty use: check every 6 mo

Check all reversing devices.

Every six months, you should verify that all installed

reversing devices work properly.

T

HE

455 D C

ONTROL

P

ANEL

Keep the control panel free from spider webs, insects,

etc. Otherwise, the control panel requires no

maintenance.

M

AINTENANCE

Page 34

June, 2004

750 Operator And

455 D Control Panel Installation Manual

Figure 14. When you check the oil, make sure the oil

level falls between the minimum and maximum marks

on the oil dip stick