Controlled Products Systems Group 107725 User Manual

Page 10

C

ONNECT

THE

H

YDRAULIC

L

INES

Caution: It is important that the hydraulic lines

be kept clean of any debris.

The drive unit and power unit are connected by two

hydraulic lines, each with an outside diameter of 5/16 in.

(0.8 cm), an inside diameter of 5/32 in. (0.4 cm), and a

2,500 psi (170 bar) rating.

Caution: After removing the nylon piping, do not

rotate the splined shaft while you are connecting the

hydraulic lines to avoid squirting hydraulic fluid.

Remove the nylon piping connecting the two hydraulic

pipe fittings on the drive unit. Clean up any spilled

hydraulic fluid.

Be sure the hydraulic lines are free of any debris by

flushing them with a jet of compressed air. Then attach

one line to each fitting on the drive unit.

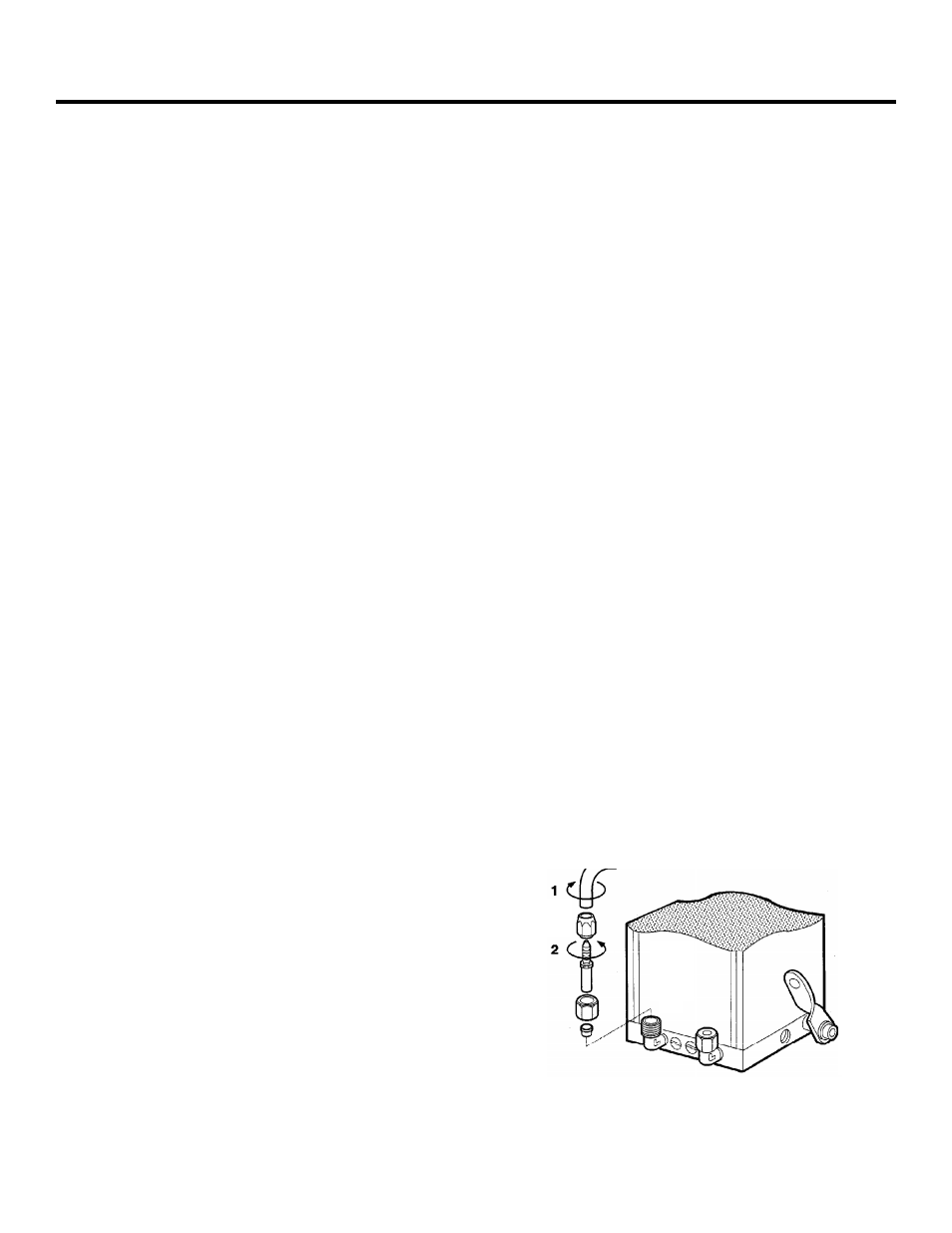

Next you attach the other end of the hydraulic lines to the

pipe fittings on the power unit (see Figure 7; additional

information can be found in the technical drawing on

page 21. Attaching the correct line to the correct fitting is

important. Make sure that the hose on the end of the

drive unit that is on the closing side of the gate/fence line

attaches to the hydraulic pipe fitting in the power unit

that is nearest the green bypass valve screw. This

connection insures that the green valve controls opening

pressure.

S

YNCHRONIZE

THE

H

YDRAULIC

S

YSTEM

Next you need to disengage the hydraulic system in order

to synchronize it.

Inside the power unit is the Manual Release lever that

disengages the hydraulic system (see Figure 1). Make sure

the Manual Release lever is turned toward you and down

to disengage the hydraulic system.

Now you can synchronize (set) the hydraulic system to the

closed position by turning the splined shaft in the closing

direction. Turn the shaft as far as it will go. To prevent

the piston in the drive unit from bottoming in its cylinder,

next turn the splined shaft about 5 deg in the opening

direction.

The position of the shaft now corresponds to the fully

closed position of the gate leaf. The hydraulic system is

now synchronized (set).

Caution: The splined shaft must not be moved from

its closed position until the gate leaf shoe that holds

the gate leaf has been attached.

Figure 7. Connect the hydraulic line to the power unit.

See the technical drawing on page 21 for more infor-

mation.

Page 10

June, 2004

750 Operator And

455 D Control Panel Installation Manual

I

NSTALL

THE

G

ATE

L

EAF

S

HOE

If the vertical distance between the finished grade

under the gate and the bottom of the gate leaf is

more than 1 1/4 in. (see Figure 4), you need to do one

of the following:

•

Install a length of appropriately sized pipe

between the sleeve that fits around the splined

shaft of the operator and the gate leaf shoe.

•

Construct a shear-pin assembly to accommodate

the extra vertical distance. The assembly is

welded to the bottom of the gate leaf shoe on one

end and to the sleeve for the splined shaft of the

pinion on the other end (see Figures 8 and 9).

Such an assembly requires a bottom hinge and

also protects the pinion and splined shaft in the

event something hits the gate with great force.

Installing the gate leaf shoe involves making the gate

leaf shoe, positioning it, and welding it to the splined

shaft sleeve. If you are retrofitting the 750 Operator

to an existing gate, these tasks require you to remove

the gate leaf from its hinges. If you are using a shear-

pin assembly, refer to Figures 9 and 10 to determine

what you should weld together.

The gate leaf shoe is designed to carry the weight of

the gate leaf and transfer the weight to the splined

shaft. The shoe surrounds the 90-deg gate-post

corner of the gate leaf to carry the gate and to act as

a lower hinge. The shoe is made of a U-shaped

section and a vertical section (see Figure 9). Later you

will weld the bottom of the U-shaped section to the

sleeve for the splined shaft (or to the shear-pin

assembly, which is welded to the sleeve).

Since the gate leaf shoe holds the gate leaf, both

sections must be made of steel at least 1/4 in. (0.6

cm) thick. The U-shaped section of the shoe must be