455 d c, On t r ol, Anel – Controlled Products Systems Group 1042011577 User Manual

Page 16: Ns tal latio n

Page 16

November, 2003

400 Operator And

455 D Control Panel Installation Manual

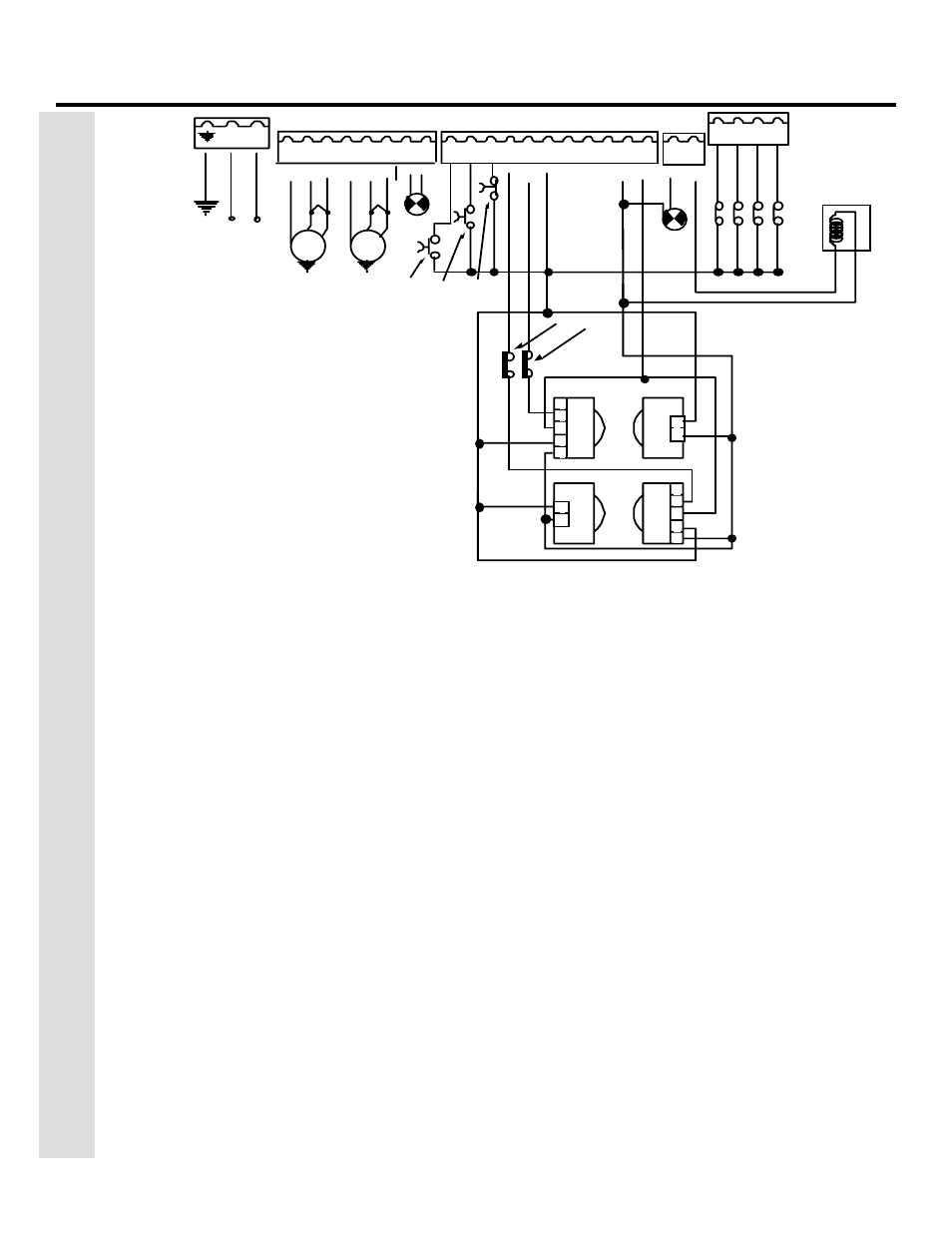

NOTE : In order to c om ply with UL 325, two s ets

of FA A C photobeams m us t be ins talled. One s et

s hould be 6 in. outs ide the c los ed gate(s ) and ac t

as a c los ing rev ers ing dev ic e. A nother s et s hould

be 6 in. bey ond the s wing of the gate(s ) and ac t

as an opening rev ers ing dev ic e. The ins taller is

res pons ible for determining the appropriate

m ounting height.

22 23 24 25

1

2

3

4

5

6

7

8

N

L

9

10 11 12 13 14 15 16 17 18 19

115 V A C +/- 10%

or

230 V A C +6/ -10%

50-60 Hz

20 21

-

S TOP

OP E N

OP E N

(1 of 2)

24V

+

FS W

OP

C L

-

FS W

-

-

+

W .LIGHT

24 vdc

3 W

LOCK

E LE CTRIC LOCK

1

2

1

2

3

4

5

1

2

3

4

5

1

2

FS W OP

FS W CL

Other safeties

LA MP

BL

UE

MOTOR 1

C 1

M1

OP

C OM

C L

BL

UE

MOTOR 2

C 2

M2

OP

C OM

C L

Figure 10.

The terminal strip wiring of the

450 D with photobeams

You cannot check the motor’s direction of rotation

without these circuits (jumpers) or the accessories.

When properly prepared for testing, the LEDS FSWOP,

STOP, and FSWCL should be illuminated (see figure 12

on page 17).

WARNING! Running the operator—even for

testing purposes—without a connected reversing

device is potentially dangerous. Do not place

yourself within the path of the moving gate

during your test.

Disengage the operator(s) with the Manual Release

key (see operator installation manual), and open the

gate by hand about halfway.

Next, engage the operator(s) with the Manual Release

key so that you can check the rotation of the

motor(s).

To activate the operator(s) momentarily short across

terminals 9 and 14.

Turn on the main power and send an activating signal

to the operator. The gate leaf (or leaves) should open.

If a gate leaf closes, then you need to turn off the

main power and reverse the connection of the red

and black wires on terminal block J4 for the operator

controlling that leaf. Then you need to recheck the

rotation direction again.

After having completed your test of the motor’s

direction of rotation, replace any test circuits you

installed (between terminals 11 and 16, between 12

and 19, and between 13 and 19) with the proper

reversing and stop devices. The instructions for

installing such accessories follow.

C

ONNECT

O

THER

D

EVICES

WARNING! Turn the main power off before you

make any electrical connections.

P

OWER

S

UPPLY

FOR

A

CCESSORIES

: You can access a 24

VDC output for supplying power to accessories

through terminals 17 or 18, (+) and 14 or 15 or 16, (-

) on terminal block J1. In most cases, this source can

be used to power 24 VDC accessories.

N

OTE

: The 455 D control panel allows a

maximum accessory load of 800 mA.

R

EVERSING

D

EVICES

: Reversing devices include

photocells, inductive loops, and so forth. All of the

reversing devices should have contacts of the

normally closed (N.C.) type. Where you connect a

device depends on whether you want the device to

operate during opening or during closing.

N

OTE

: UL does not recognize the FAAC system

with loop detectors or safety edges. FAAC

photobeams must be used to comply with UL

325.

To wire photobeams, refer to page 19 (see FSWOP for

opening photobeams, and FSWCL for closing

photobeams). Photobeams must be connected as

shown. See also page 19 for the wiring of inductive

loops. If using more than one reversing device, they

must be wired in series.

T

HE

455 D C

ON

T

R

OL

P

ANEL

I

NS

TAL

LATIO

N

I

NS

T

R

U

C

TIO

N

S