Cashco 1000 HP Differential User Manual

Page 9

9

IOM-1000HP-Dif fer en tial

13. Bench test unit for suitable operation and

seat leak age. NOTE: Regulators are not

normally tight shutoff devices. Pressure

must build above setpoint for best shutoff.

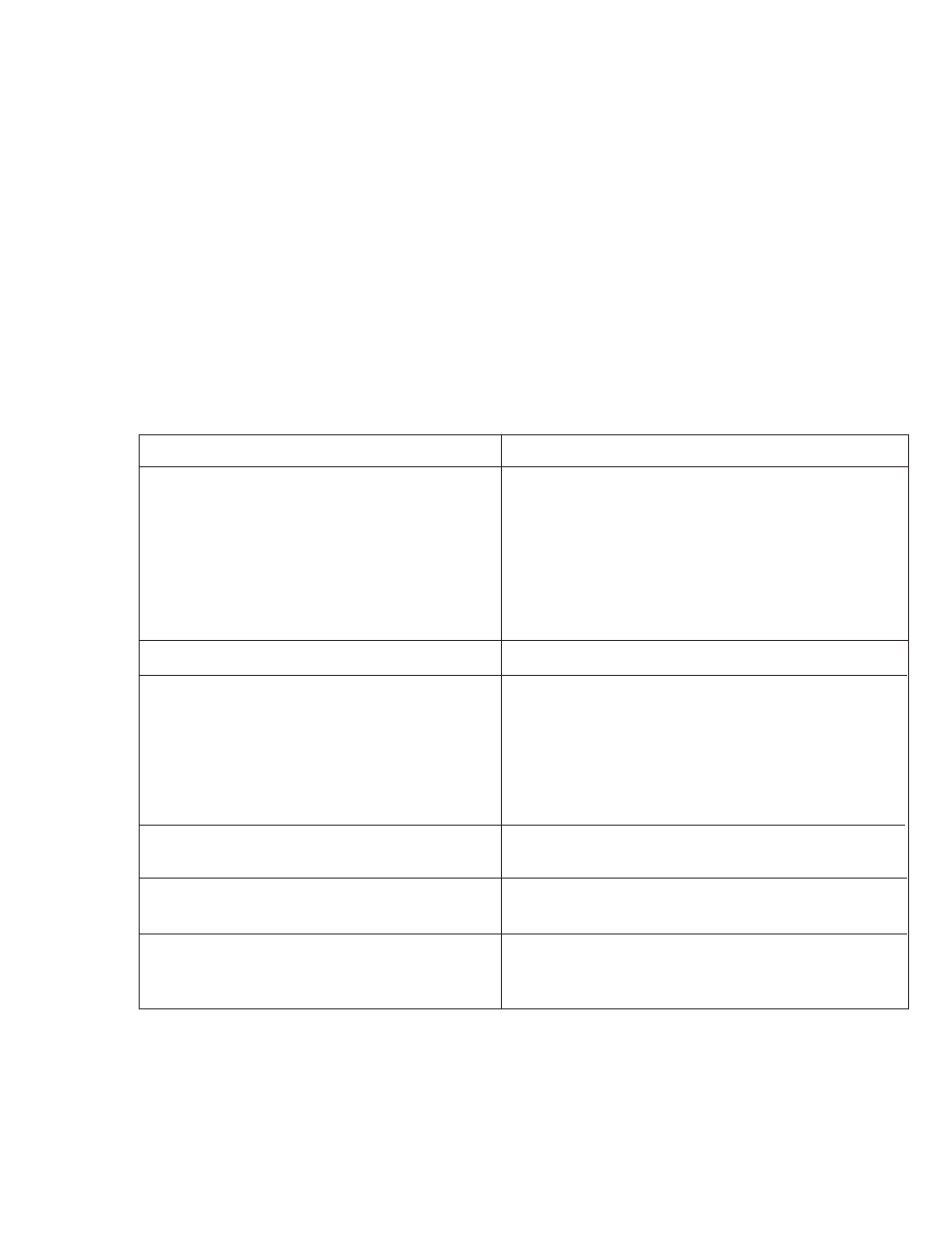

1. Erratic operation; chattering.

Possible

Causes

Remedies

A. Oversized regulator; inadequate rangeability.

A1. Check actual fl ow conditions, resize regulator for

minimum and maximum fl ow.

A2.

Increase

fl ow rate.

A3. Decrease regulator pressure drop; decrease inlet

pressure by placing a throttling orifi ce in inlet

piping

union.

A4. Replace full orifi ce with reduced orifi ce; i.e. new

cylinder

required.

B. Worn piston/cylinder; inadequate guiding.

B. Replace trim.

C. Flow induced instability.

C1. Get straight runs of piping (5 diameters upstream,

10 downstream) to and from regulator.

C2. Ensure outlet velocity is not excessive; use pipe

reducer close to regulator outlet.

C3. Add next higher range spring. Contact factory.

C4. If composition diaphragm, switch to metal

diaphragm.

D. Improper (oversized) jet.

D. Replace existing piston with new piston with

proper

jet.

E. Plugged trim.

E. Remove trim and check for plugged holes in

piston, or debris in guide zone or jet zone.

F. Unstable loading pressure.

F1. Stabilize loading pressure; i.e. pump, control

valve,

etc.

F2. Air in loading piping. Vent spring chamber.

VII. TROUBLE SHOOTING GUIDE

SECTION VII

14. Soap solution test around cylinder (21)-to-

body (1) connection for leakage. Test pres-

sure should be a min i mum of 100 psig at the

inlet or actual service con di tions if higher.