Cashco SA4 User Manual

Model ca4/sa4

INSTALLATION, OPERATION & MAINTENANCE MANUAL (IOM)

IOM-CA4/SA4

11-13

I. DESCRIPTION AND SCOPE

Models CA4/SA4 are pressure reducing regulators used to control downstream (outlet or P2) pressure. Sizes are

3/4" (DN20), 1" (DN25), 1-1/2" (DN40), and 2" (DN50). With proper trim uti li za tion, the unit is suitable for liquid or

gaseous service. (NOTE: This product was formerly identifi ed as a Model C4 or S4; a Model CA4/SA4 and C4/S4

are one and the same product.)

MODEL CA4/SA4

CA4 and SA4 - ULTRA HIGH PURITY, PRESSURE LOADED

PRESSURE REDUCING REGULATORS

SECTION I

II. REFERENCES

Refer to Technical Bulletin CA4/SA4-TB for tech ni-

cal specifi cations of a Model CA4/SA4 reg u la tor.

ABBREVIATIONS

CCW – Counter

Clockwise

CW –

Clockwise

ITA

– Inner Trim Assembly

SECTION III

SECTION II

III. INSTALLATION

1. Install per direction of fl ow arrow indicated on

body, or "IN" and "OUT" markings.

2. Regulator may be rotated around pipe axis 360

degrees. For ease of maintenance, the rec om-

mend ed orientation is with the loading chamber

(4) upwards.

3. Provide space below, above, and around reg u la tor

for removal of parts during maintenance.

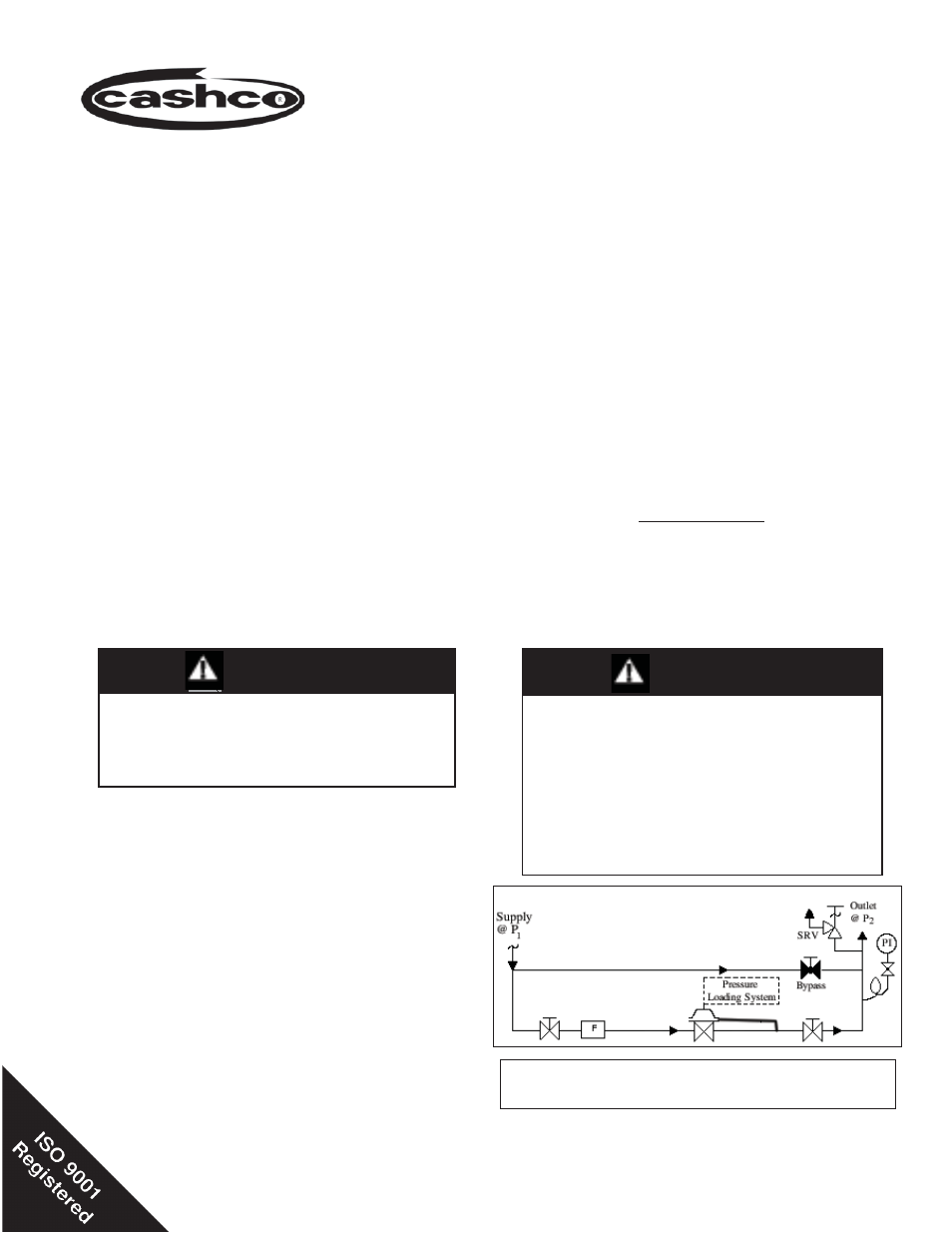

4. Install block valves and pressure gauges to pro-

vide means for adjustment, operation, bypass, or

removal of the regulator. A UHP fi lter is rec om-

mend ed before inlet to remove typical pipe line

debris from entering valve and damaging internal

“soft goods”, primarily the dynamic seal and valve

seat.

CAUTION

Installation of adequate overpressure pro tec tion

is recommended to pro tect the reg u la tor and all

downstream equip ment from dam age in the event

of reg u la tor failure.

CAUTION

DO NOT HYDROSTATIC TEST THROUGH AN

IN STALLED UNIT; ISOLATE REGULATOR FROM

TEST. The "Outlet" rating as printed on the

nameplate is the rec om mend ed “upper op er at-

ing limit” for the sens ing di a phragm. Higher

pres sures could cause internal dam age. In ad-

di tion, note on the nameplate that the Inlet and

Outlet pres sure and temperature ratings are at

different levels.

Recommended Piping Schematic

for Pressure Reducing Station