Caution – Cashco 1000 HP Differential User Manual

Page 7

7

IOM-1000HP-Dif fer en tial

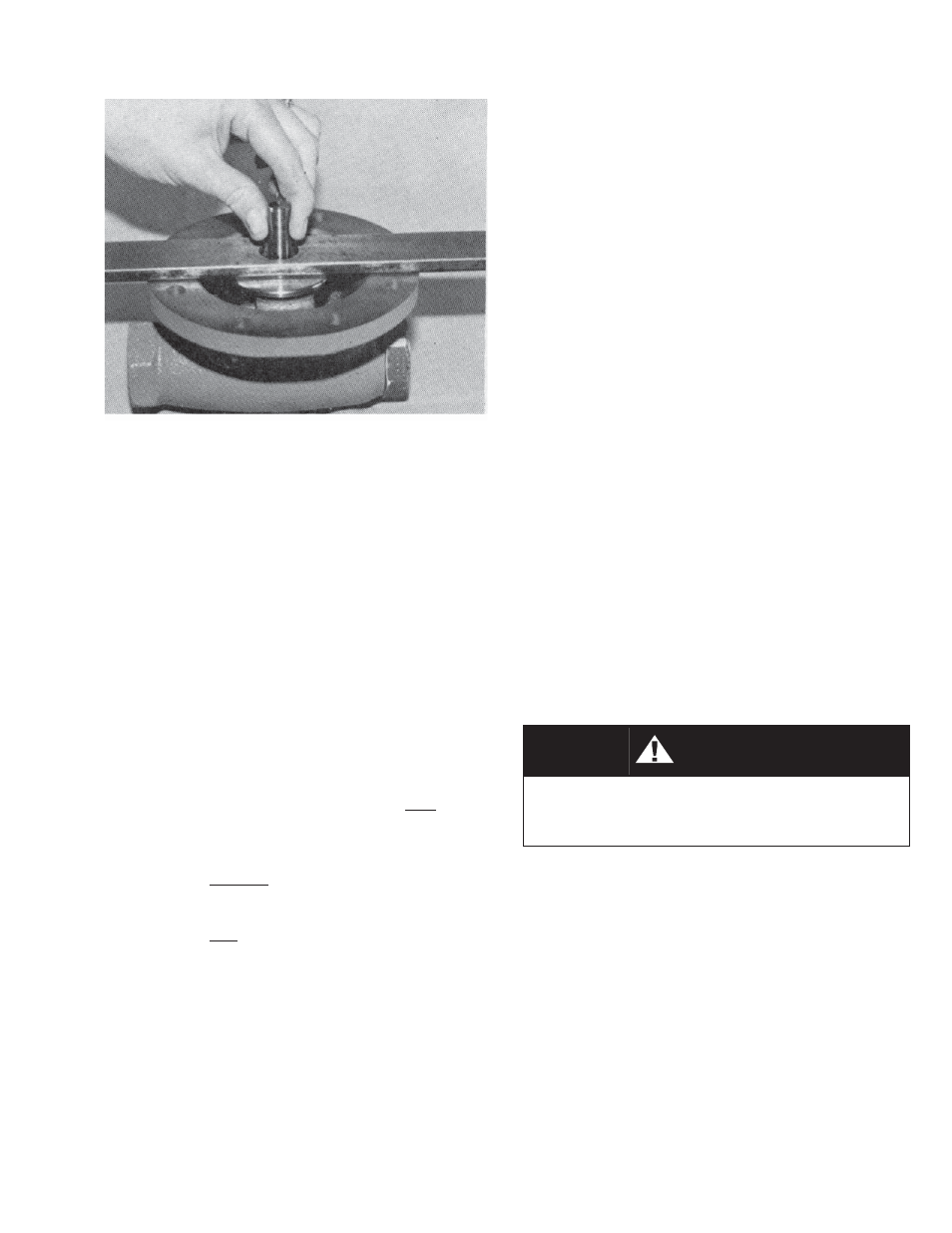

3. Follow procedure “Sub-Section B., Di a phragm

Re place ment” to the point of removing

diaphragm(s) (20), Step 13. Remove di a-

phragm gasket (19) and pusher plate stud

gasket (12). Obtain a fl at 12" x 1-1/2" x 1/4"

(15 mm x 40 mm x 6 mm) plate bar with a

3/4" (20 mm) hole drilled in the center. “Hook”

the pusher plate stud (13) into the rocker arm

(14) prongs properly. Pull fi rmly up on the

pusher plate stud (13) to ensure that all slack

is removed from the mechanism and that the

piston (24) is seated fi rmly. Relax the pulling

and place the fl at bar over the pusher plate

stud (13) with the stud (13) passing through

the hole of the bar. Again, pull fi rmly up to

remove mech a nism slack. One of three po si-

tions will be reached:

a. Diaphragm setting too high. Pusher plate

stud (13) will lift the fl at bar over 0.020"

(.51 mm).

b. Diaphragm setting acceptable. Bar lifted

between 0.010"–0.020" (.25–.51 mm).

c. Diaphragm setting too low. Bar lifted

less than 0.010" (.25 mm), or failed to be

lifted.

4. The castle style stud nut (10) has six locations

per revolution to align the stud nut (10) slots

with the drilled hole through the pusher plate

stud (13). Each stud nut (10) slot represents

a movement up/down of 0.010" (.25 mm).

NOTE: The ideal diaphragm setting is 0.015"

(.4 mm) high. Better performance is usually

ob tained when the diaphragm is at this value,

rather than a lower level. As the measuring of

a thou sandths of an inch is diffi cult with such

a pro ce dure, it is rec om mend ed that the “null”

position be found where the diaphragm(s) (20)

is fl ush with the body (1) fl ange (bar approxi-

mately at 0.000"). Remove the pusher plate

stud (13), rotate the stud nut (10) one or two

slots CCW to bring the setting to 0.010–0.020"

(.25–.51 mm) high.

5. Place cotter pin (15) through the slot, bend

over ends.

6. Continue reassembly per Sub-Section B,

Di a phragm Replacement, Step 16.

E. Trim Removal and Replacement:

1. Install body (1) horizontally in a vise with the

spring chamber (2) directed upwards, and the

body (1) held at the outlet end.

2. Use a box end wrench, or socket, with a lever

length of at least 24 inches (610 mm), and

place over the hex surfaces of the cylinder

(21). The wrench should be rapped with a

hammer to loosen.

3. Continue to unscrew cylinder (21) until re-

moved. The piston (24) and piston collar (23)

should come out by gravity with the cylinder

(21) removal.

CAUTION

Take precautions not to allow the piston (24)

to fall from within the cylinder (21); tip cylinder

with hex end down.

4. If an Option 1000-17 piston spring (30) is uti-

lized, it also should be removed and re placed

at trim re place ment.

5. Inspect inside surface of cylinder (21) at four

points:

a. Seat (21.2) ring. Check for erosion/wear

on seat ing surfaces. If wear is ex ces sive,

consider utilizing Option 1000-15, stellited

seat surface.

b. Seat (21.2). Check for wire drawing

be tween cylinder (21.1) and seat (21.2)

where pressed in. If wear exists here, an

Option 1000-14, integral seat, should be

utilized as a replacement.