Cashco 2171 User Manual

Back pressure / relief regulators

MODELS 1171 AND 2171

BACK PRESSURE / RELIEF REGULATORS

SECTION I

I. DESCRIPTION AND SCOPE

The instructions in this manual will refer to both models, unless otherwise stated.

INSTALLATION, OPERATION & MAINTENANCE MANUAL (IOM) IOM-1171/2171

12-13

SECTION II

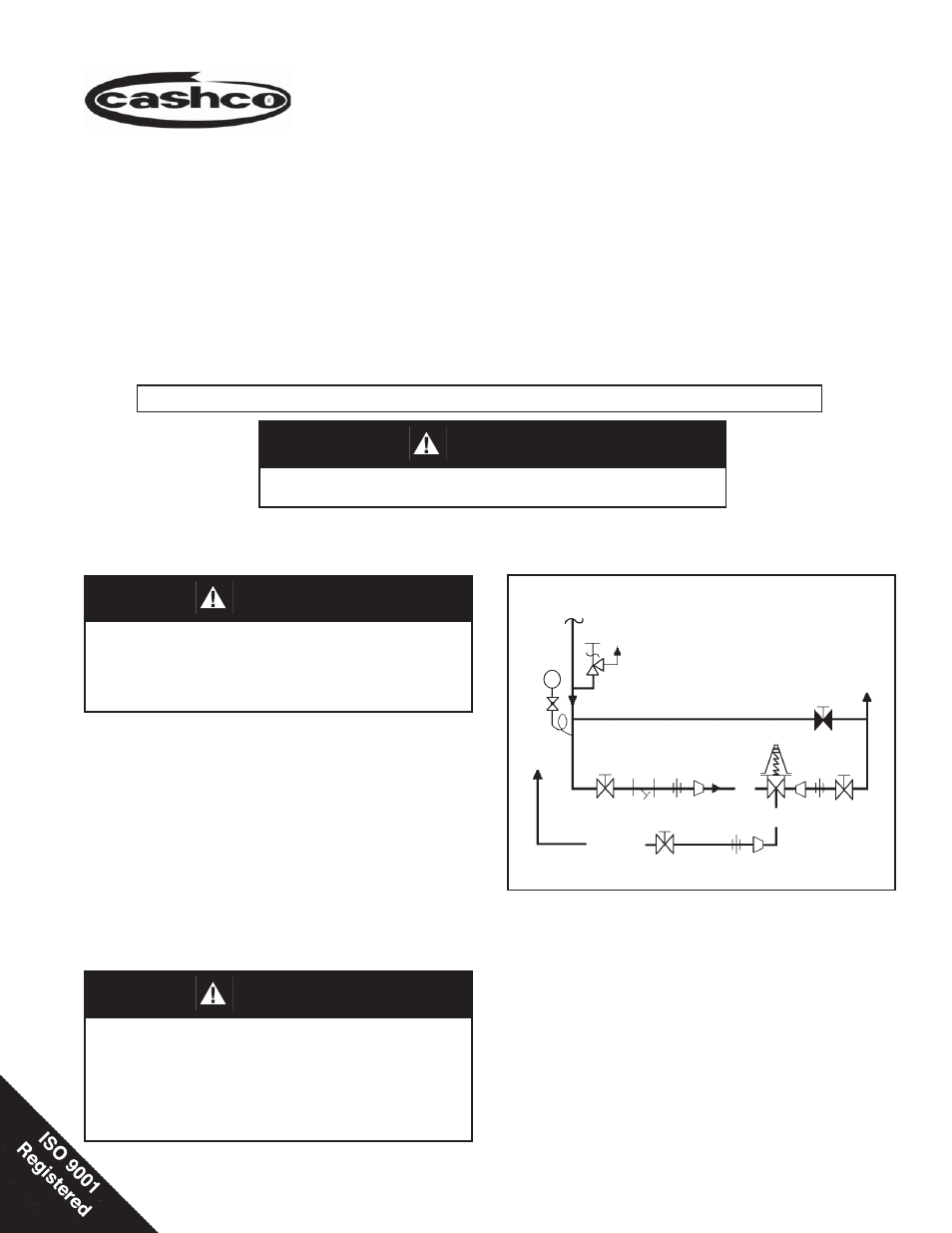

Recommended Piping Schematic For Back Pressure/Relief Station

Models 1171/2171

BP/Relief Regulator

Models 1171 and 2171 are back pressure/relief regulators used to control upstream (inlet or P

1

) pressure. Sizes

are 1/4" and 3/8" (DN8 and DN10). The Model 2171 is also available in 1/2" (DN15) size. The 1171 is a bronze

bodied unit; the 2171 incorporates a stainless steel body. With proper trim utili za tion, both units are suitable for

liquid, gaseous and steam service (the 2171 can also be used with various chemi cals). Refer to Tech ni cal Bul le tins

1171-TB and 2171-TB for specifi c design conditions and selection rec om men da tions.

1. An inlet block valve should always be in stalled.

2. If service application is continuous such that

shut down is not readily accomplished, it is rec-

ommended that an inlet block valve, outlet block

valve, and a manual bypass valve be installed.

3. Pipe unions should be installed to allow removal

from piping.

4. An inlet pressure gauge should be located ap prox-

i mately ten pipe diameters upstream, and within

sight. An outlet pressure gauge is op tion al.

II. INSTALLATION

5. All installations should include an upstream relief

device if the inlet pressure could exceed the pres-

sure rating of any equip ment or the max i mum inlet

pressure rating of the unit.

6. Clean piping of all foreign material including chips,

welding scale, oil, grease and dirt before installing

the regulator. Strainers are recommended.

7. In placing thread sealant on pipe ends prior to en-

gagement, assure that excess material is re moved

and not allowed to enter regulator upon startup.

Supply

@ P1

SRV

System

P1

P1

P2

Dis charge

CAUTION

For welded installations, all internal trim parts, seals and

diaphragm(s) must be removed from reg u la tor body prior

to welding into pipeline. The heat of fusion welding will

dam age non-metallic parts if not re moved. NOTE: This does

not apply to units equipped with extended pipe nip ples.

CAUTION

This is not a safety device and must not be sub sti tut ed for a code

approved pressure safety relief valve or rupture disc.

CAUTION

The maximum inlet pressure is equal to 1.5 times the

larger number of the stated range spring on the name-

plate, and is the rec om mend ed "upper op er a tive limit" for

the sens ing diaphragm. Higher press ures could dam age

the di a phragm. (Field hydro static tests fre quent ly destroy

dia phragms. DO NOT HYDRO STATIC TEST THRU AN

IN STALLED UNIT; ISO LATE FROM TEST.)