Cashco 1000 Cryogenic User Manual

Cashco Sensors

INSTALLATION, OPERATION & MAINTENANCE MANUAL

MODEL 1000HP - CRYOGENIC

PRESSURE REDUCING REGULATOR

SECTION I

IOM-1000HP-

Cryogenic

12-13

I. DESCRIPTION AND SCOPE

The Model 1000HP-5 and 1000HP-36 are cryogenic pressure reducing regulators used to control down stream

(outlet or P

2

) pressure to levels above 10 psig, and up to 300 psig (size dependent). Sizes are 1/2", 3/4", 1",

1-1/2" and 2".

The unit is designed for liquid or gaseous service with proper trim utilization, and proper jet selection.

Refer to Technical Bulletin 1000HP-CRYO-TB for sizing, application and selection recommendations.

Installation, operation and maintenenace manuals (IOM's) exist for the following other Model 1000 products:

1000HP-Basic

1000LP-Basic

1000HP-Differential

SECTION II

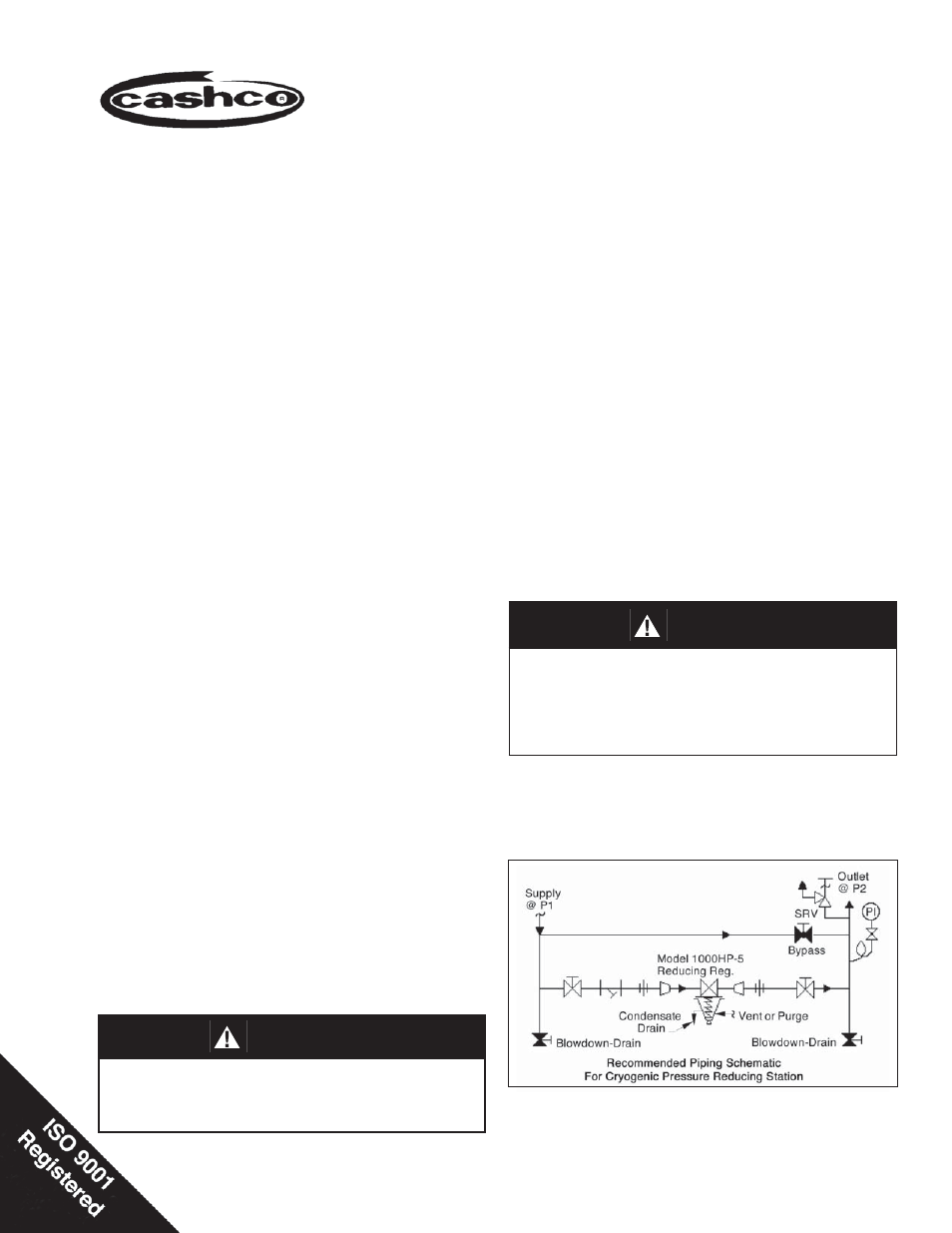

II. INSTALLATION

1. An inlet block valve should always be in stalled.

2. If service application is continuous such that

shut down is not readily accomplished, it is rec-

om mended that an inlet block valve, and a manual

bypass valve be in stalled.

3. Pipe unions must be installed to allow re mov al

from piping. Trim can only be changed by unit

removal from pipeline. If fl anges are uti lized, a lap

joint fl ange is required on the inlet end of the valve

to help align bolt holes as the cylinder screws into

place.

4. An outlet pressure gauge should be located ap-

prox i mate ly ten pipe diameters down stream, and

within sight.

5. All installations should include a down stream relief

de vice if the inlet pressure could exceed the pres-

sure rating of any downstream equip ment or the

maximum outlet pressure rat ing of the unit.

6. Clean the piping of all foreign ma te ri al in clud ing

chips, welding scale, oil, grease and dirt before

in stall ing the valve. Strain ers are rec om mended.

CAUTION

Installation of adequate overpressure pro tec tion is recom-

mended to pro tect the reg u la tor from over pres sure and

all down stream equip ment from dam age in the event of

regulator failure.

WARNING

The maximum outlet pressure listed on the name plate is

the "upper operative limit" for the sensing diaphragm.

Higher pressures could damage the diaphragm. (Field

hy dro static tests frequently de stroy dia phragms. DO

NOT HY DRO STAT IC TEST THRU AN INSTALLED UNIT;

ISO LATE FROM TEST.)