Warning – Cashco 1000 HP Differential User Manual

Page 4

4

IOM-1000HP-Dif fer en tial

SECTION VI

WARNING

(19) is not used with a composition (soft)

diaphragm.)

NOTE: The text hereafter will refer to:

a. The -1+8 double di a phragm op tion al

con struc tion (-1+6 single di a phragm

con struc tion is sim i lar. Text regarding

com po si tion diaphragm(s) (20) applies

only to -1+6 op tion). Text portions deal-

ing with body spacer (42), diaphragm

spacer (41) and sep a ra tion of total di a-

phragm (20) quantity into two “stacks”

applies only to -1+8 option.

b. The “pusher plate and stud” (13) as a

single part for 1/2" – 1-1/4" sizes and

as two separate parts, a “pusher plate”

(5) and a “pusher stud” (13) , for 1-1/2"

and 2" sizes.

7. Pry up the diaphragm(s) (20) and diaphragm

gas ket (19) around the perimeter of the body (1)

di a phragm fl ange to ensure the diaphragm(s)

(20) are not “stick ing”. (Di a phragm gasket

(19) is not used with a com po si tion (soft)

diaphragm.)

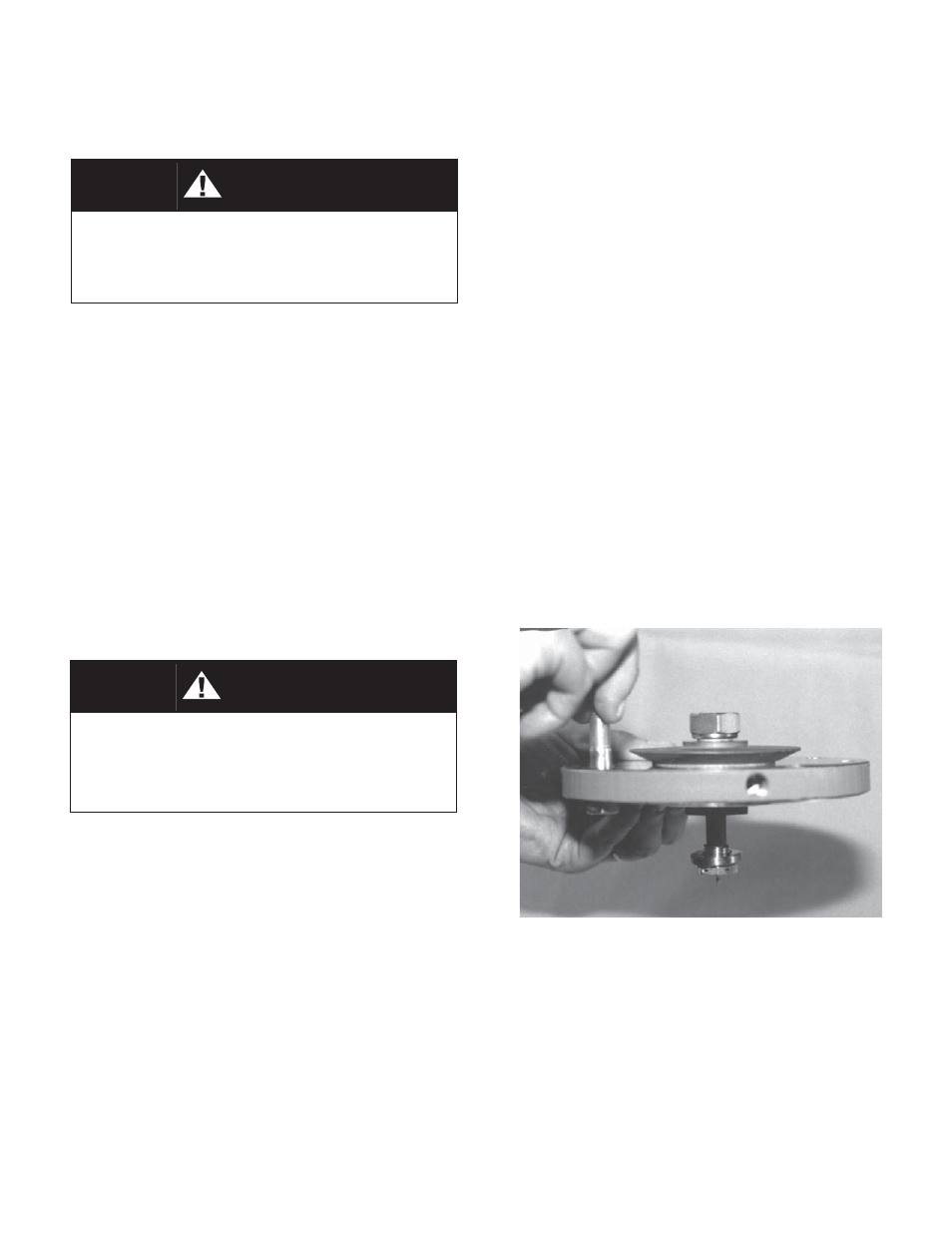

8. Remove diaphragm subassembly by sliding

the push er plate and stud (13), body spacer

WARNING

2. Remove closing cap (31). Relax range spring

(27) by turning adjusting screw (6) CCW until

re moved from spring chamber (2).

3. Paint or embed a match mark between body

casting (1), spring chamber casting (2), and

body spacer (42) along fl anged area.

4. Remove all diaphragm fl ange nuts (9) and

bolts (8). Remove nameplate (28).

5. Remove spring chamber (2), spring button (4)

and range spring (27).

6. Pry up the diaphragm(s) (20) and diaphragm

gasket (19) around the perimeter of the spring

chamber (2) fl ange to ensure the diaphragm(s)

(20) are not “sticking”. (Di a phragm gasket

VI. MAINTENANCE

SYSTEM UNDER PRESSURE. Prior to per form ing

any maintenance, isolate the regulator from the

system and relieve all pressure. Failure to do so

could result in personal injury.

A. General:

1. Maintenance procedures hereinafter are based

upon removal of the unit from the pipeline

where installed.

2. Owner should refer to owner’s procedures for

re mov al, handling and cleaning of reusable

parts, and dis pos al of non-reusable parts, i.e.

gaskets.

3. If desired, the gaskets may be lubricated with

a light oil provided it is com pat i ble with the

fl uid.

B.

Diaphragm

Replacement:

1. Securely install the body (1) in a vice with the

spring chamber (2) directed upwards.

SPRING UNDER COMPRESSION. Prior to re mov-

ing fl ange bolts, relieve spring compression by

back ing out the adjusting screw. Failure to do

so may result in fl ying parts that could cause

personal injury.

Diaphragm subassembly consists of items (10), (11),

(12), (13), (15), (16), (20), (41), (42) and (50). (Metal

di a phragm design.)

(42) and nut (11) in the direction of the reg u -

la tor inlet, approximately 1/2"–3/4" (15-20

mm) The pusher plate and stud (13), stud nut

(10), and stud collar (16) should dis en gage

with the rocker arm (14) slot. Lift ver ti cal ly

for di a phragm subassembly re mov al, care-

fully hold ing the assembly at its outer edge

to prevent the body spacer (42) from falling

from be tween the diaphragm(s) (20).