Cashco POSR-2 User Manual

Model posr-2, Pilot operated pressure re duc ing regulator

MODEL POSR-2

PILOT OPERATED PRESSURE RE DUC ING REGULATOR

SECTION I

I

. DESCRIPTION AND SCOPE

The POSR-2 is a pilot operated pressure reducing reg u la tor used to control downstream (P

2

) pressure. Sizes are

1", 1-1/2", 2", 3" and 4" (DN25, 40, 50, 80, 100). The unit is suitable for steam service only. Refer to Technical Bul-

letin POSR-2-TB for design conditions and selection recommendations. NOT RECOMMENDED FOR DEAD END

SERVICE.

SECTION II

II. INSTALLATION

A. General:

IOM-POSR-2

12-13

INSTALLATION, OPERATION & MAINTENANCE MANUAL (IOM)

6. Clean the piping of all foreign material in-

clud ing chips, welding scale, oil, grease and

dirt before installing the regulator. Strainers

are recommended.

B. Piping the Valve:

1. An inlet block valve should always be in-

stalled.

2. If service application is continuous such that

shut down is not readily accomplished, it is

recommended that an inlet block valve, outlet

block valve, and a manual bypass valve be

installed.

3. Pipe unions are recommended for NPT

screwed in stal la tions to allow removal from

piping.

4. An outlet pressure gauge should be located ap-

prox i mate ly ten pipe diameters down stream,

and within sight.

5. All installations should include a downstream

re lief device if the inlet pressure could ex-

ceed the pressure rating of any downstream

equip ment or the maximum allowable outlet

pres sure rating of the unit.

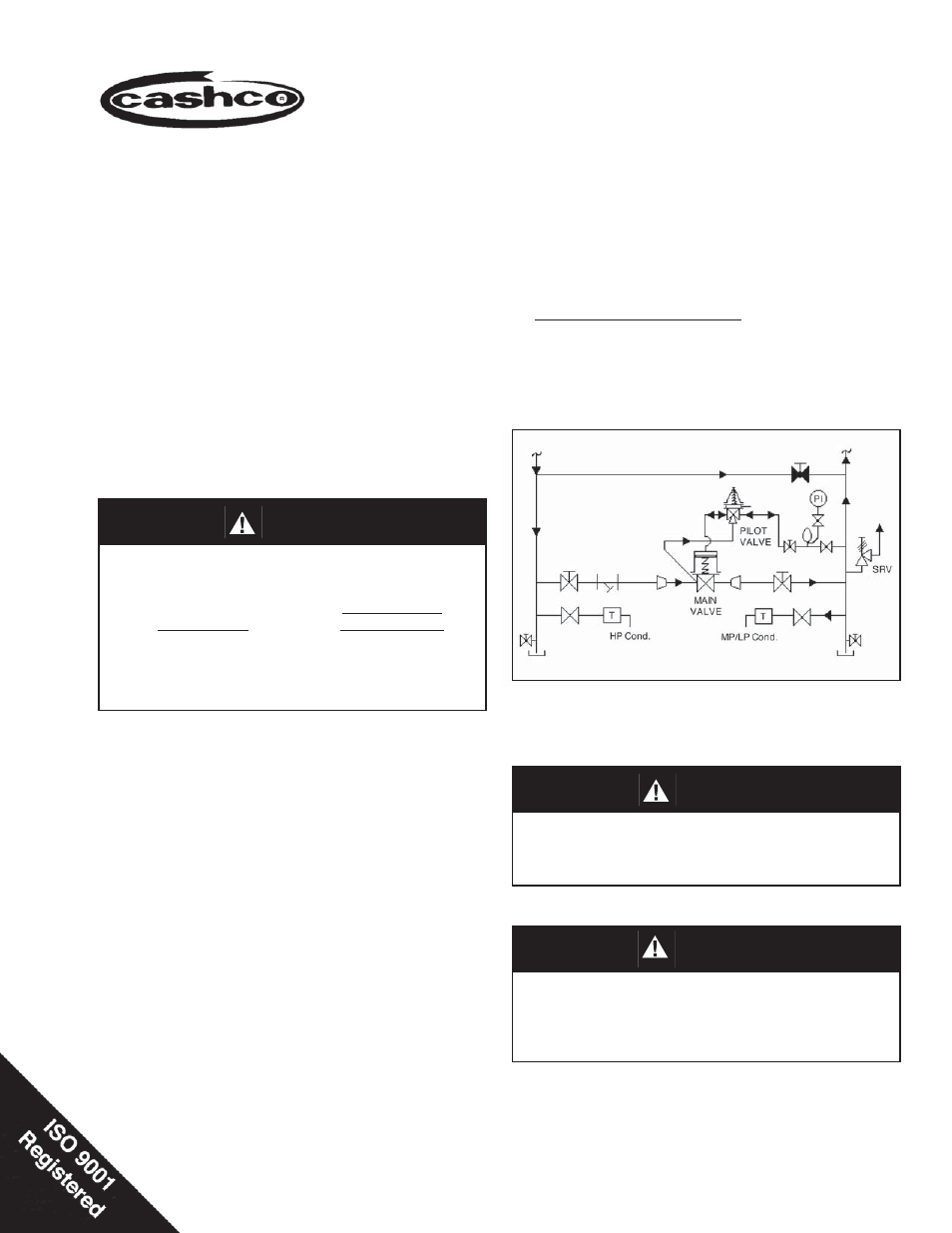

FIGURE 1

Recommended Piping Schematic for POSR-2

WARNING

Do not dead end (no fl ow demand) downstream of POSR-2

if P

1

- Inlet Pressure is greater than max i mum allowable

outlet design pressure.

Max.

Allowable

Spring Range

Outlet Pressure

5-15 psig (0.34–1.03 Barg)

100 psig (6.9 Barg)

10–40 psig (0.69–2.8 Barg)

200 psig (13.8 Barg)

30–80 psig (2.1–5.5 Barg)

200 psig (13.8 Barg)

70–150 psig (4.8–10.3 Barg)

200 psig (13.8 Barg)

CAUTION

Installation of adequate overpressure pro tec tion is recom-

mended to pro tect the reg u la tor from overpressure and

all down stream equip ment from damage in the event of

regulator failure.

CAUTION

For welded installations, all internal trim parts, seals and

diaphragm(s) must be removed from reg u la tor body prior to

welding into pipeline. The heat of fusion welding will dam-

age non-metallic parts if not re moved. NOTE: This does

not apply to units equipped with extended pipe nip ples.