Cashco 8310HP - Differential User Manual

Nb pb qb

INSTALLATION, OPERATING AND

MAINTENANCE INSTRUCTIONS

Install with arrow on body (1) pointing in direction of flow.

Install an external sensing line (1/2" O.D. tubing min.) from the 3/8" NPT

connection in needle valve (39) to a point downstream, preferably at gauge

location.

Install oil loading pressure sensing line to spring chamber (13) connec-

tion.

For long operational life with minimum maintenance, install a strainer in

the upstream line. If valve pipe line is expanded to a larger pipe line, al-

ways connect steam sensing line to the larger pipe line. To increase the

differential setting, turn the adjusting screw (32) clockwise. To decrease

the differential setting, turn the adjusting screw (32) counterclockwise.

Before disassembling the valve for maintenance work, always release the

tension on the range spring (28) by turning the adjusting screw (32) coun-

terclockwise.

For examination or replacement of diaphragms (20), remove spring cham-

ber (13). Place wrench on flats of pusher plate (17). Remove nut (24), and

pressure plate (22), then remove upper set of diaphragms (20), diaphragm

spacer (26), body spacer (25), and lower set of diaphragms (20).

For examination or replacement of plug (12), proceed as noted above,

then remove stem lock nut (19). Remove bottom flange (3) and remove

plug and stem subassembly (12). Upon reassembly make certain the dia-

phragm case (14) is pulled down tight to make metal to metal contact.

The diaphragm setting must be flush to ensure proper valve travel (with

plug against the seat, adjust the pusher plate (17) so that the gasket (18)

face of the pusher plate (17) is flush with the top of the case (14) flange

and then tighten the stem lock nut (19) by holding upper flats on the pusher

plate (17)).

STABILIZING NEEDLE VALVE – The needle valve (39) is shipped in a

full open position. If the system is unstable due to pressure fluctuations,

slowly close this valve (39) until system becomes stable. This valve (39)

should never be in a fully closed position.

Turn handle of bleeder valve (37) counterclockwise to bleed off air en-

trapped above oil to ensure stable operation.

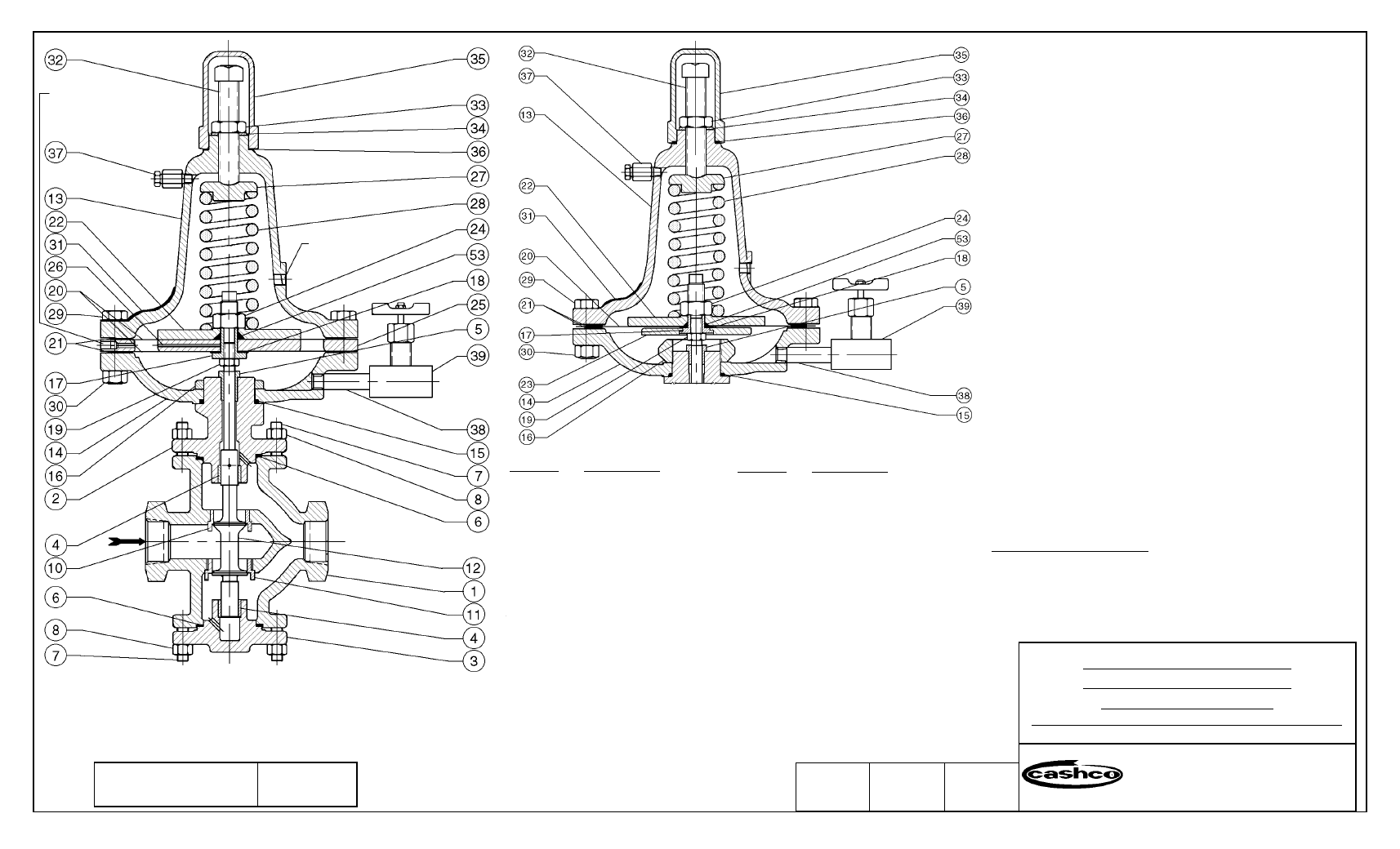

ITEM NO.

DESCRIPTION

1

BODY

2

BONNET

3

BOTTOM FLANGE

4

GUIDE BUSHING

5

STEM BUSHING

6

BODY GASKET

7

BODY STUD

8

BODY STUD NUT

10

UPPER SEAT RING

11

LOWER SEAT RING

12

VALVE PLUG ASSEMBLY

12.1

PLUG

12.2

STEM

12.3

PIN (GROOVE)

13

SPRING CHAMBER

14

DIAPHRAGM CASE

15

O-RING

16

BONNET NUT

17

PUSHER PLATE

18

PUSHER PLATE GASKET

19

STEM LOCK NUT

ITEM NO.

DESCRIPTION

20

DIAPHRAGM

21

DIAPHRAGM GASKET

22

PRESSURE PLATE

23

LOWER PRESSURE PLATE

24

PRESSURE PLATE NUT

25

BODY SPACER

26

DIAPHRAGM SPACER

27

SPRING BUTTON

28

RANGE SPRING

29

FLANGE BOLT

30

FLANGE NUT

31

NAME PLATE

32

ADJUSTING SCREW

33

ADJ. SCREW LOCK NUT

34

SEAL WASHER

35

CLOSING CAP

36

CLOSING CAP GASKET

37

BLEEDER VALVE

38

PIPE NIPPLE

39

NEEDLE VALVE

53

O-RING

8310HP-1+8

DOUBLE DIAPHRAGM TOPWORKS

(“HP” VARIATION ONLY)

8310HP-1+6

SINGLE DIAPHRAGM TOPWORKS

DATE

TEMPORARY LITHO

08/96

Cashco, Inc.

P.O. Box 6

Ellsworth, KS 67439-0006

PH (785) 472-4461 • FAX (785) 472-3539

E-mail: [email protected] or [email protected]

MODEL “8310HP-1+8”, OR

MODEL “8310HP-1+6”, OR

MODEL “8310LP-1+6”

DIFFERENTIAL PRESSURE REDUCING REGULATOR

NB PB QB

Vent to Atmosphere -

Leakage of Steam or Oil

Indicates a Diaphragm

Failure. (1/8" NPT)

Loading Connection.

(1/4" NPT)