Fluid Components International VORTAB User Manual

Fluid Components International Equipment

This page is subject to proprietary rights statement on last page

General

This document describes the procedures required to install, and maintain the Vortab Insertion Panel (VIP), Vortab Insertion Sleeve (VIS), Vortab Meter

Run (VMR), Vortab Short Run (VSR), Vortab Elbow (VEL) and Vortab Field Kit (VFK) Flow Conditioners.

In Industrial installations, process plants are designed to minimize floor space. Abbreviated floor space can result in inadequate short runs of straight

pipe required upstream from flow meters, pumps, compressors and other critical components used in the process industries. The resulting flow

disturbances increase flow meter error, and can induce cavitation and noise in pumps, which results in excessive wear and damage.

A flow conditioner isolates flow disturbances by providing a consistent outlet flow condition regardless of inlet conditions. Because of its unique tab

design, the Vortab flow conditioner is able to provide excellent flow meter isolation, yet it creates very little pressure loss and is virtually immune to

fouling.

Vortab flow conditioners come in six basic forms: Vortab Insertion Panel (VIP), Insertion Sleeve (VIS), Meter Run (VMR), Short Run (VSR), Elbow

configuration (VEL), or Field Kit (VFK). The VIP can be configured to slide into an existing process pipe or duct and welded in place, or offered as a

flange mount version to be captured between flange faces. The VIS is sized to slide into the existing process pipe or duct. It can be welded in place

or secured with optional capture flange between flanges faces. The VMR spool piece includes the Vortab flow conditioning internals as well as the

recommended settling distance for downstream flow meters. The VSR is a stand-alone pipe section 3 pipe diameters (3D) in length that includes only

the flow conditioning internals. The VEL elbow flow conditioner can be short or long radius with a vast array of process connections and downstream

metering connections. The VFK includes all the Vortab flow conditioning internals and fabrication instructions required for assembly in the field.

Theory of Operation

Vortab flow conditioners are passive mechanical devices, which effectively establish a repeatable, symmetric, and swirl free velocity profile regard-

less of the fluid’s inlet condition. These conditioners use vortex generating tabs to amplify and accelerate the boundary layer behavior of long pipe.

The basic principles involved are vorticity generation, force cancellation, and diffusion.

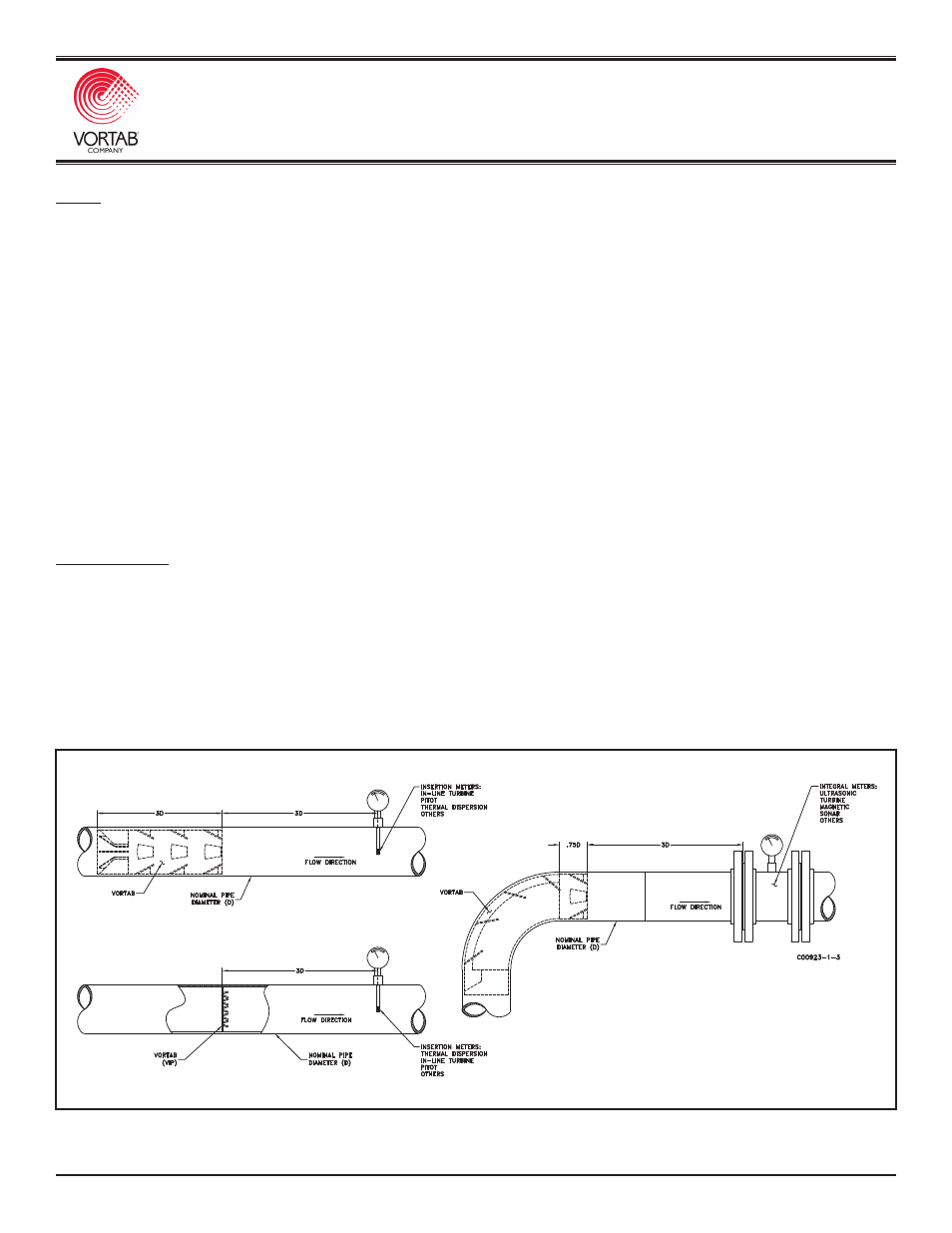

For flow meters, the Vortab flow conditioners are capable of producing uniform, non-swirling velocity profiles three pipe diameters (3D) downstream

from the Vortab. Depending on the severity of the downstream disturbance, one to five diameters (1D to 5D) of straight pipe are required after the

flow meter location. Figure 1-1 illustrates typical Vortab installations upstream from flow meters. For pumps, compressors, control valves and other

critical process equipment, the Vortab flow conditioners can be mounted directly to their downstream components. Figure 1-2 illustrates typical

installations upstream from pumps and compressors.

VORTAB Flow Conditioner

Installation and Operation Guide

Figure 1-1. Typical Vortab Installation with Flowmeters