3 instrument wiring, Recommended minimum wire gauge, Grounding – Fluid Components International FS10A User Manual

Page 8: Input power, 24 vdc, 4 power up, functional verifictaion and adjustment, 3instrument wiring, 4power up, functional verifictaion and adjustment

FS10 Series

6

Fluid Components International LLC

3

INSTRUMENT WIRING

Only qualified personnel are to wire or test this instrument. The operator assumes all responsibilities for safe practices while wiring or troubleshoot-

ing. One of the following wiring instruction and diagrams illustrate the requirements for power input, alarm and analog outputs and safety instruc-

tions for the unit being installed.

ALERT:

The Instrument contains electrostatic discharge (ESD) sensitive devices. Use standard ESD precautions when handling the

instrument.

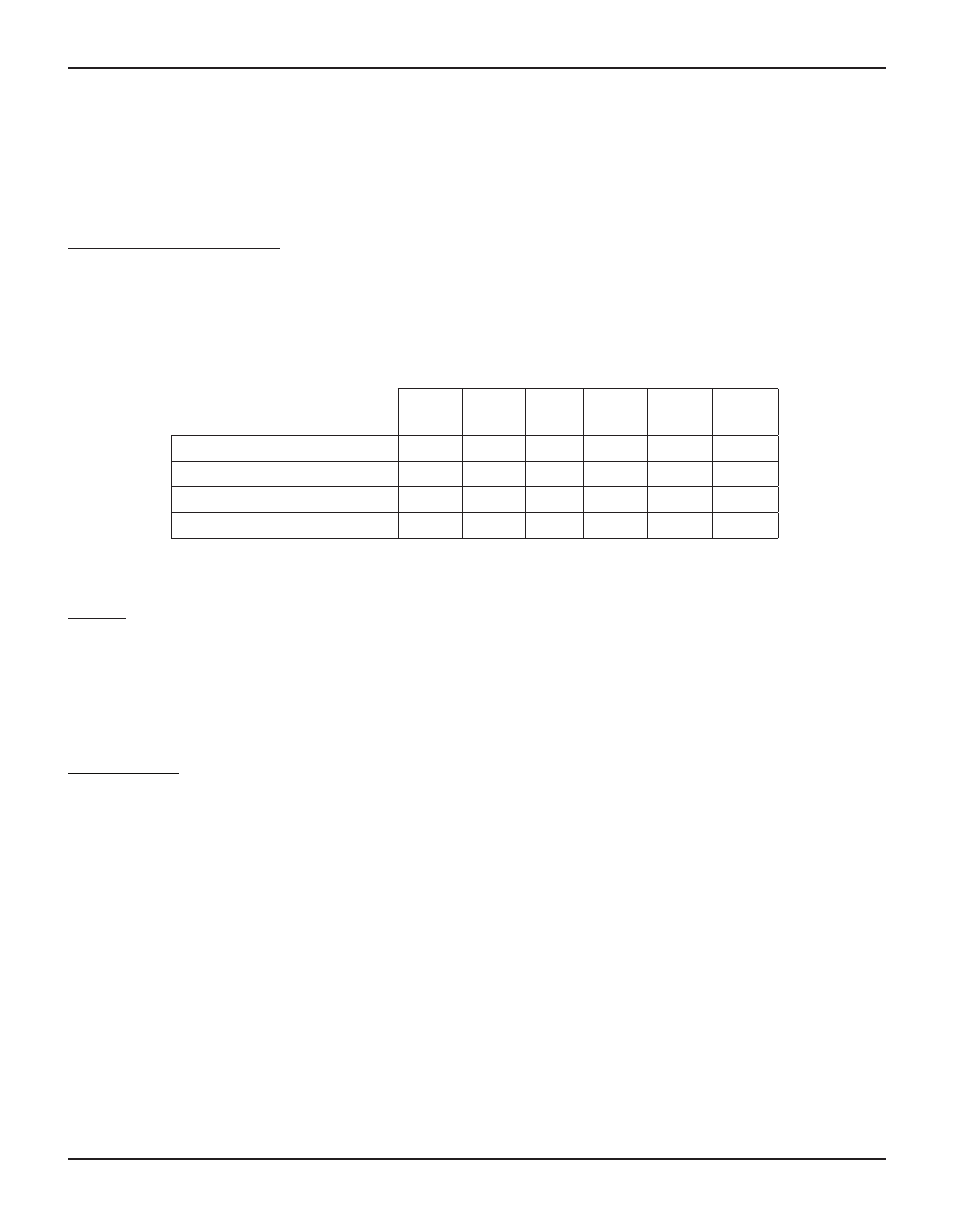

Recommended Minimum Wire Gauge

The following wire gauge chart specifies the correct wire for the distance to the power source or loads. Note that the open collector option is limited

to 50 ft. It is also recommended that the open collector cable is shielded and that it is not run in the same conduit with the power source or the relay

load.

Grounding

The switch must be properly grounded for safety and operational reasons.

The circuit board is tied to the enclosure case internally and both are tied to the probe assembly. If the installation pipe or vessel is not properly

grounded, connection to earth ground may be connected at the output connector, i.e. M12 or cable pigtail. Use the recommended wire gauge speci-

fied for the input power and distance listed in the chart above. Do not connect the earth ground to DC ground (terminals marked “GND”,

“COM” or “-”).

Input Power, 24 Vdc

FCI recommends installing an input power disconnect and a fuse near the instrument to interrupt power during installation, maintenance, calibra-

tion, alarm selection and troubleshooting procedures. Conduit should also be installed according to the local electrical codes or hazardous location

requirements.

Attach the power leads according to the Input/Output connection schematic on the following page. If the unit has an M12 interface, verify that the

mating connector pin numbers match the designations of the wiring diagram. If the unit is supplied with a cable pigtail, the flying leads should be

connected via an approved terminal block or connector in an electrically safe and approved conduit box.

Attach the wires to the relay and other functions as needed. The relay contact conditions are shown in the alarm state (de-energized). The relay’s maxi-

mum rating is 1 amp 24Vdc, 120 Vac (FM only), 24 Vdc (ATEX), resistive loads.

Refer to the next section for the set point and alarm state settings.

4

POWER UP, FUNCTIONAL VERIFICTAION AND ADJUSTMENT

Before Applying power to the instrument, it is recommended that a third party inspect the installation workmanship. Make sure wires are not pinched

or frayed. Check for matching serial numbers on the sensing element and the control circuit. Verify that the power and alarm circuits are properly

connected. Review the instrument configuration and its application.

Units supplied with LED’s will have at least one LED on or slowly blinking to indicate power on. Apply power and look for the power indicator light.

After power is established let the instrument warm up for 5 minutes. Refer to set-up on following pages. The switch must be properly grounded for

safety and operational reasons.

I/O Wiring Gauge vs. Distance

Maximum Diameter (guage)

Connection

10 ′

50 ′

100 ′

250 ′

500 ′

1000 ′

(3 m)

(15 m) (30 m)

(76 m)

(152 m) (305 m)

Input Power (24 Vdc nominal)

24

24

22

22

20

18

Relay Output (1 amp contacts)

18

16

14

12

10

X

Open Collector Output

24

22

X

X

X

X

4-20 mA Output

24

24

22

22

20

18

Table 1