Wiring, Assembling the connectors – Burkert Type 8072 User Manual

Page 19

17

Installationandwiring

7.3.1. Assembling the connectors

1

2

3

4

→

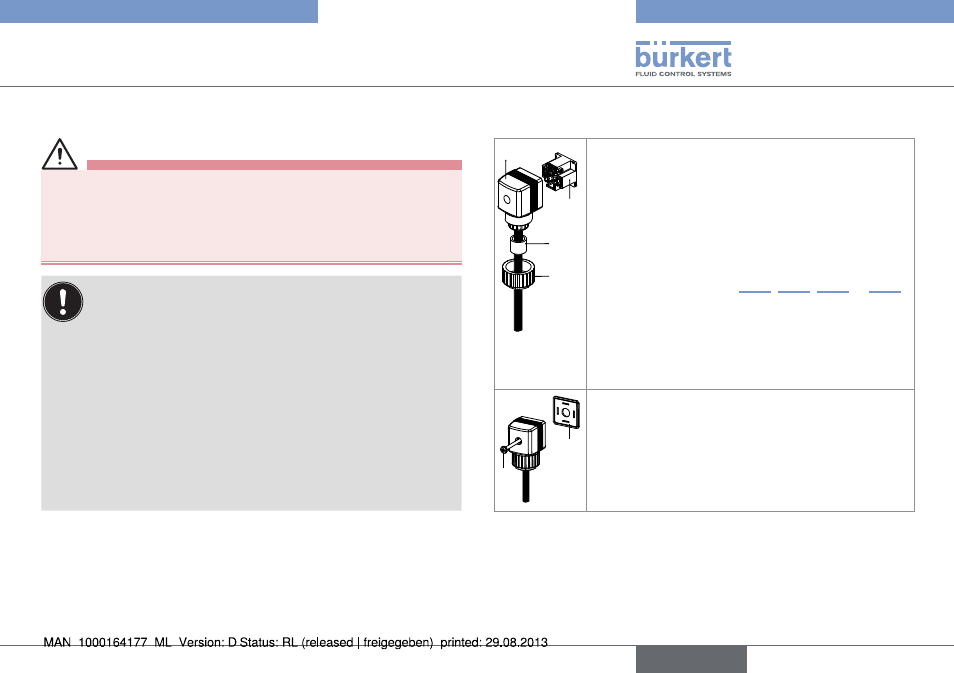

Unscrew the nut [1] of the cable gland.

→

Remove the terminal block [3] from the housing

[2].

→

Insert the cable through the nut [1] then through

the gasket [4], through the cable gland and

finally through the housing [2].

→

Make the connections to the screw terminal

block [3] (see chap. 7.3.2, 7.3.4, 7.3.6 or 7.3.7).

→

Position the terminal block [3] in steps of 90°

then put it back into the housing [2], pulling

gently on the cable so that the wires do not

clutter the housing.

→

Tighten the nut [1] of the cable gland.

6

5

→

Place the seal [5] between the connector and

the EN175301-803 fixed connector on the

device and then plug the 2508 connector into

the fixed connector.

→

Insert and then tighten the screw [6] to ensure

tightness and correct electrical contact.

Fig. 10: Assembling the female connector type 2508 (supplied)

7.3.

Wiring

danger

risk of injury due to electrical voltage

• Shut down the electrical power source of all the conductors and

isolate it before carrying out work on the system.

• Observe all applicable accident protection and safety guidelines

for electrical equipment.

• Use shielded cables with a temperature limit of 80 °C

minimum.

• Use a high quality electrical power supply, filtered and

regulated.

• Protect the power supply by means of a 1 A fuse and a

switch.

• Protect the power supply of each transistor by means of a

125 mA fuse.

• Protect the relays by means of a max. 3 A fuse and a

circuit breaker (depending on the process).

• Do not apply both a dangerous voltage and a safety extra-

low voltage to the relays.

English

installation and wiring