Maintenance of components, Ul handling, Maintenance of components 9.3 – Burkert Type 8644 User Manual

Page 64

64

Maintenance, Troubleshooting

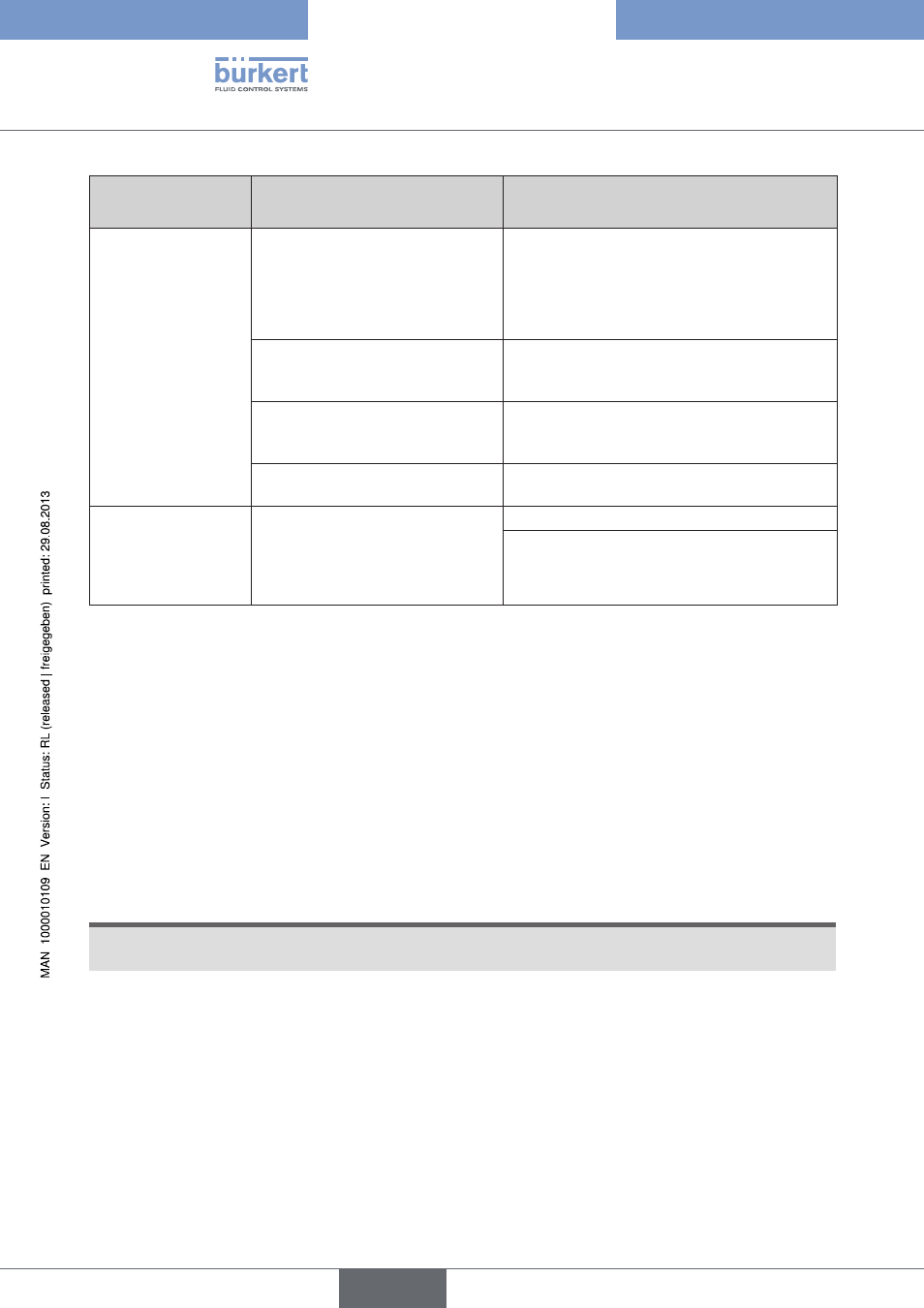

Malfunction

possible cause

remedial action

Valves switch with

a delay or blow off

at the deaeration

connections

Inadequate or no pressure supply

Design the pressure supply with the largest

→

possible volume (even for upstream devices

such as pressure controllers, maintenance

units, shut-off valves, etc.)

Minimum operating pressure ≥ 2.5 bar

Valves are not in home position

(de-energized) during pressure

build-up

Pressurize the valve block before you switch

→

the valves.

Deaeration of the exhaust air ducts

inadequate due to too small or dirty

silencers (back pressures).

Use appropriately sized silencers or

→

expansion tanks. Clean dirty silencers.

Impurities or foreign objects in the

pilot valve or main valve

Change the valve.

→

Leaking valve blocks

Missing or crushed O-rings

between the modules;

Missing or incorrectly positioned

profile seals between valve and

pneumatic base module

Determine the leaks or missing seals.

→

Insert missing seals or replace damaged

→

seals.

Maintenance of components

9.3.

ul handling

9.3.1.

Valve clusters of Type 8644 with UL license may be converted by UL-certified production, installation, or service

centers only.

Do not reach into the system. This refers in particular to:

Damage of components,

•

Expansion of the valve clusters by modules; the catch mechanism of the pneumatic modules must be released

•

for this.

NoTE!

Replacement of the valves is a permitted maintenance operation; follow the general safety instructions.

Typ 8644

deutsch