Fluid installation, Pneumatic connections - feed, Fluid installation 8.5 – Burkert Type 8644 User Manual

Page 60

60

Installation

fluid installation

8.5.

DANgEr!

risk of injury from high pressure in the equipment!

Before dismounting pneumatic lines and valves, turn off the pressure and vent the lines.

•

Design the connections with the largest possible volume.

•

Close the open connections not required with lock screws.

•

The connections for the pilot control exhaust air (x) must not be sealed.

•

Check that connections 1 and 3 or 5 have been configured correctly; these must not be mixed up.

•

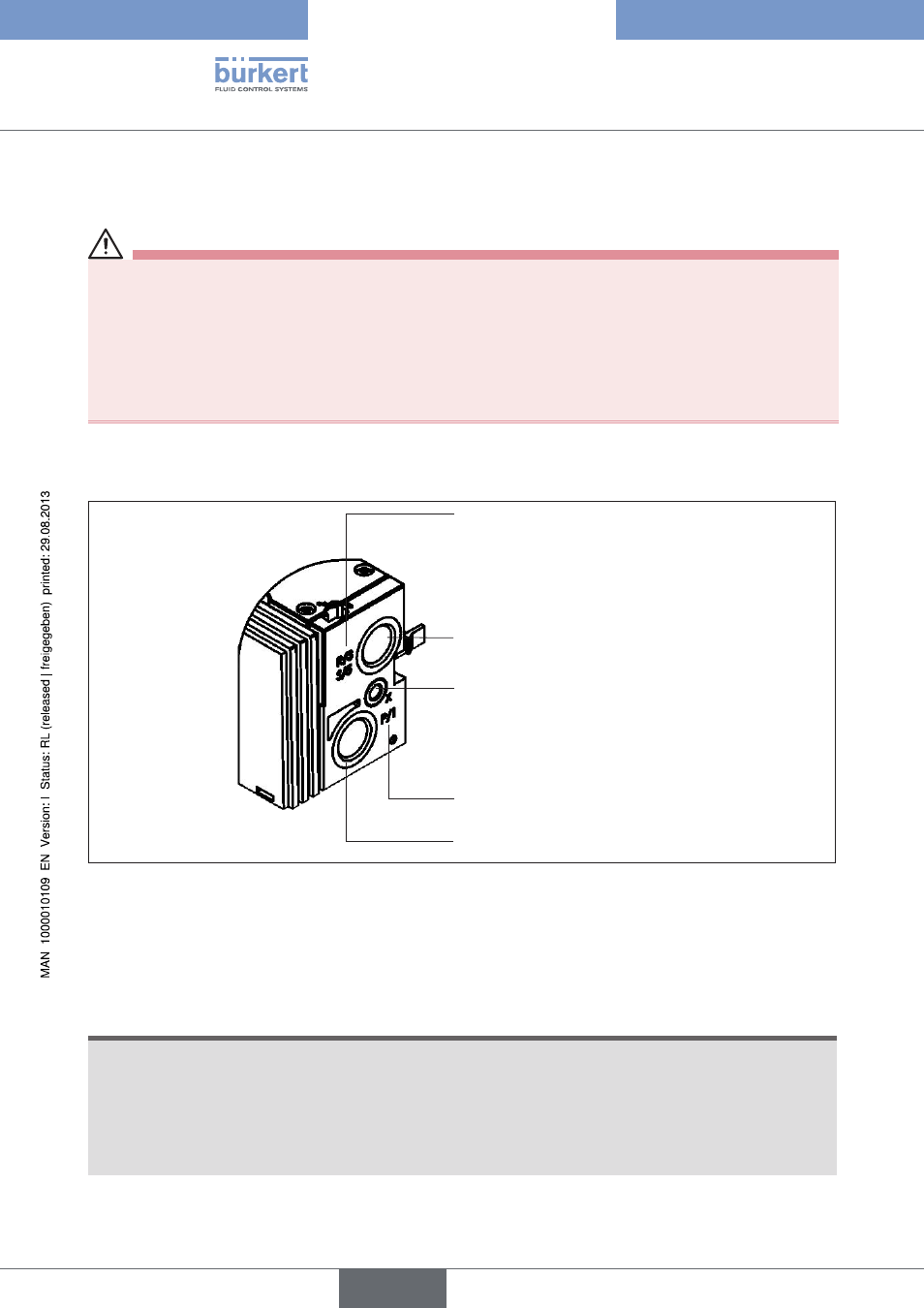

pneumatic connections - feed

8.5.1.

Exhaust air

Pressure supply connection

X channel:

Standard version:

Deaeration of the control valves

Control assist air version:

P connection for control valves

(R/S) 3/5

(P) 1

Pneumatic connections

Figure 33:

Procedure

Depending on the version, insert (D10) or screw (G1/4, NPT 1/4) the connections to the corresponding working

→

connections.

NoTE!

For the plug-in connections the hose pipes must meet the following requirements:

Minimum hardness of 40 Shore D (in accordance with DIN 53505 or ISO 868);

•

Outer diameter in accordance with DIN 73378 (max. permitted deviation ± 0.1 mm of the nominal dimension);

•

Burr-free, cut off at right angles and undamaged on the outer diameter;

•

The hose pipes must be pressed all the way into the plug-in connections.

•

Typ 8644

deutsch