Electrical installation – Burkert Type 8694 User Manual

Page 16

16

Electricalinstallation

Important information for the problem-free functioning of

the device:

• The installation must not cause back pressure to build up.

• Select a hose for the connection with an adequate

cross-section.

• The exhaust air line must be designed in such a way that

no water or other liquid can get into the device through

the exhaust air port (3) or (3.1).

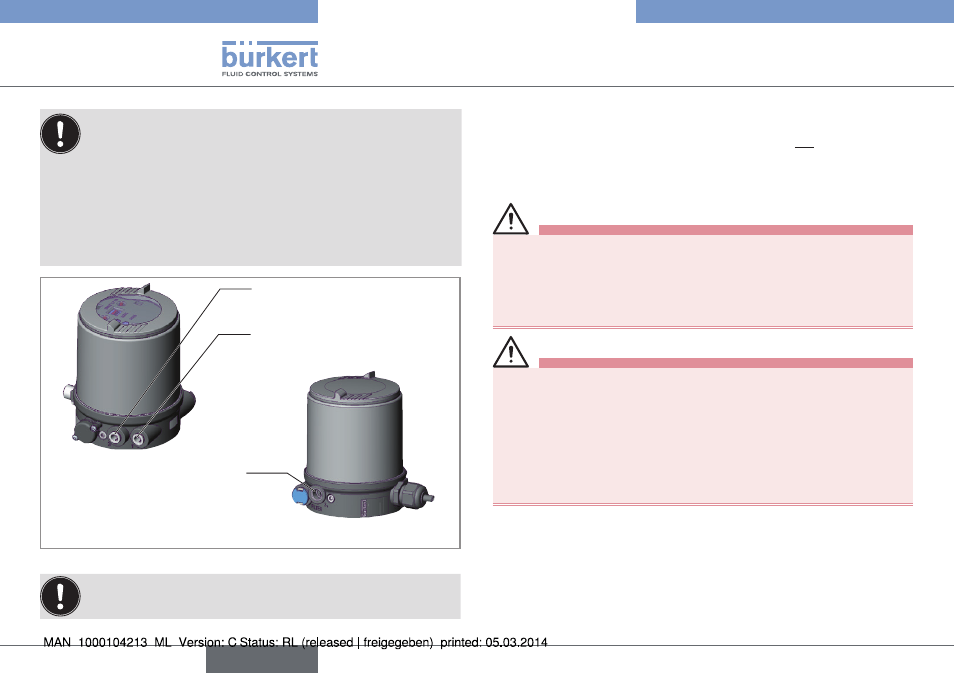

Additional exhaust air port

(label: 3.1)

only for Type 23xx and 2103

with pilot-operated control system

for high air output (actuator size ø 130)

Pilot air port

(label: 1)

Exhaust air port

(label: 3)

Fig. 8:

Pneumatic Connection

Caution:

(Exhaust air concept): In compliance with protection

class IP67, an exhaust air line must be installed in the dry area.

9. ELECTRICAL INSTALLATION

All electrical inputs and outputs of the device are not galvanically

isolated from the supply voltage.

9.1. Safety instructions

DANGER!

Risk of electric shock!

• Before reaching into the system, switch off the power supply

and secure to prevent reactivation!

• Observe applicable accident prevention and safety regulations

for electrical equipment!

WARNING!

Risk of injury from improper installation!

• Installation may be carried out by authorized technicians only

and with the appropriate tools!

Risk of injury from unintentional activation of the system and

an uncontrolled restart!

• Secure system from unintentional activation.

• Following installation, ensure a controlled restart.

9.2. Electrical installation 24 V DC

Two kinds of connections are used for the electrical bonding of the

positioner:

• Cable gland with screw-type terminals

• Multi-pole with circular plug-in connector M12 x 1, 8-pole

english

Type 8694