Burkert Type 2731 User Manual

Page 24

replacement for control function a

→

Clamp the valve body in a holding device

(applies only to valves not yet installed).

NoTiCe!

damage to the diaphragm or the seat contour!

▶ When removing the actuator, ensure that the valve is in open

position.

→

Pressurize lower pilot air port of the actuator with compressed

air (5 bar): valve opens.

→

Loosen the body screws / body nuts.

→

Remove the actuator from the body.

→

Unscrew old diaphragm. If attachment is with a bayonet catch,

remove the diaphragm by rotating it through 90°.

→

Install new diaphragm.

→

Align diaphragm.

the marker flap of the diaphragm must be perpendicular to

the direction of flow (see “Fig. 16”)!

→

Place actuator back on the body.

→

Insert the body screws / body nuts

and lightly cross-tighten until

the diaphragm is between the body and actuator.

do not tighten the body screws / body nuts

yet.

→

Actuate the diaphragm control valve twice.

→

Without pressurization tighten the body screws / body nuts

to the permitted tightening torque (see “Tab. 11: Tightening

torques for diaphragms”).

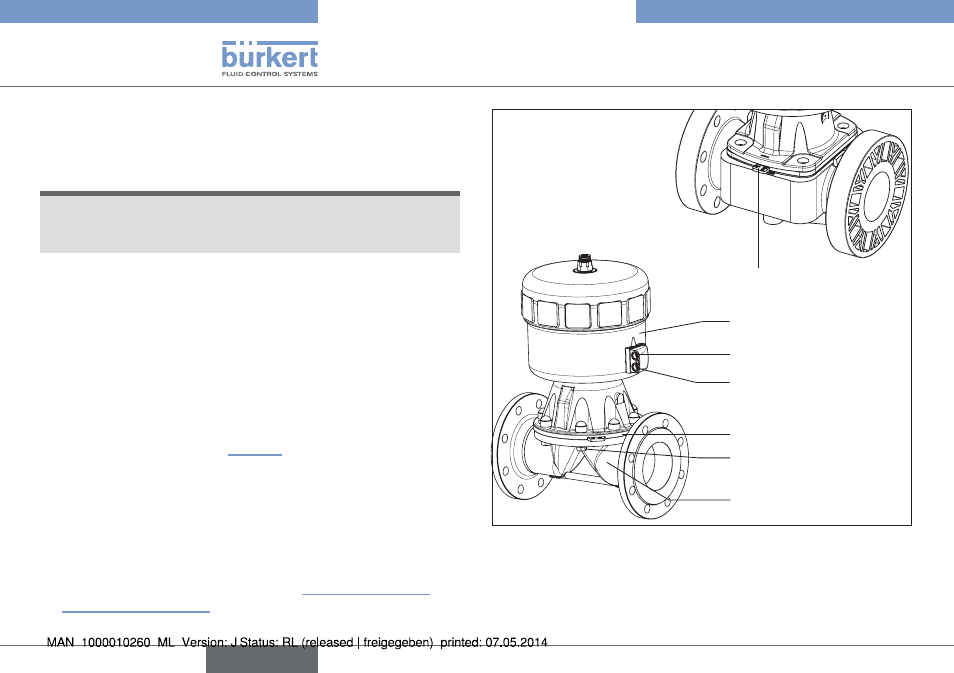

Actuator

Body screws / body nuts

Valve body

Lower pilot air port

Upper pilot air port

Diaphragm

Marker flap of the

diaphragm

Fig. 16: Repairs

replacement for control functions B

→

Clamp the valve body in a holding device

(applies only to valves not yet installed).

→

Loosen the body screws / body nuts.

24

Repairs

english

Type 2730 / 2731 DN 65-100