Burkert Type 2731 User Manual

Page 16

7.2.1 installation position general

installation for self-drainage of the body

It is the responsibility of the installer and operator to

ensure self-drainage.

installation for leakage detection

One of the bores (in the actuator base) for monitoring

leakage must be at the lowest point.

7.2.2 installation position 2/2-way valve

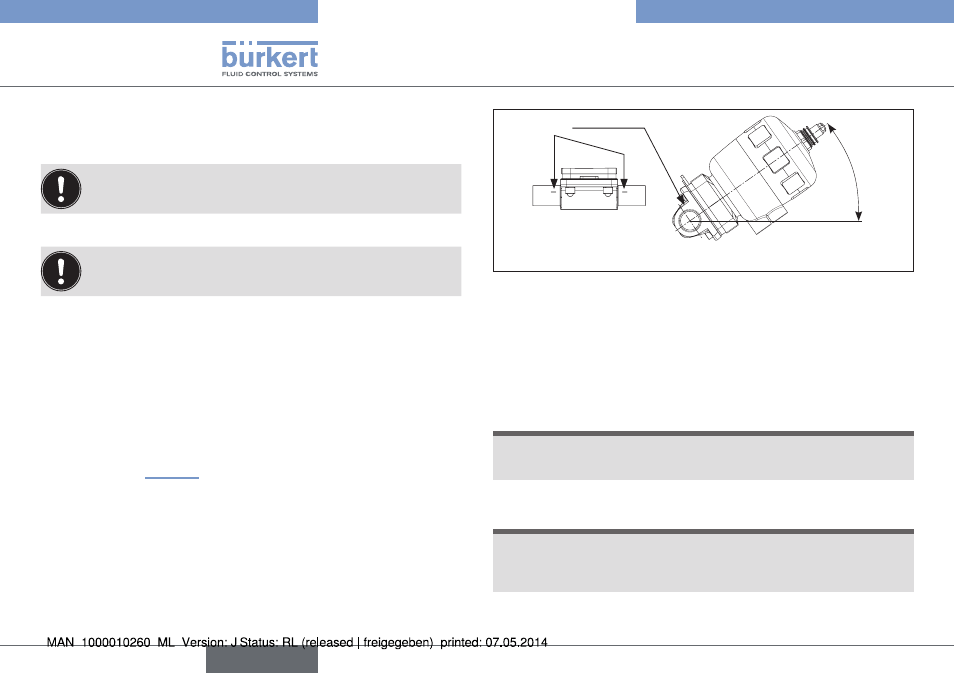

• The piston-controlled diaphragm control valve can be installed in

any installation position, preferably with the actuator face up.

To ensure self-drainage:

→

Install body inclined by an angle α = 15° – 35° to the horizontal.

→

Observe an inclination angle of 1° – 5° to the line axis.

Forged body: Mark on the body must point upwards (12 o’clock

position, see “Fig. 11”).

→

One of the bores (in the actuator base) for monitoring leakage

must be at the lowest point.

Angle α: 15 °– 35°

Inclination to the line axis 1° – 5°

Mark

α

Fig. 11: Installation position for self-drainage of the body

7.2.3 preparatory work

→

Clean pipelines (sealing material, swarf, etc.).

→

Support and align pipelines.

devices with vs/va welded body:

NoTe!

damage to the diaphragm or the actuator!

▶ Before welding in the body, remove the actuator.

Remove the actuator from the valve body:

NoTiCe!

damage to the diaphragm or the seat contour!

▶ When removing the actuator, ensure that the valve is in open

position.

16

Installation

english

Type 2730 / 2731 DN 65-100