Media – Burkert Type 2702 User Manual

Page 10

10 - 2702

T

ECHNICAL

D

ATA

hsi

l

g

n

e

CONSTRUCTION OF THE CONTROL VALVE

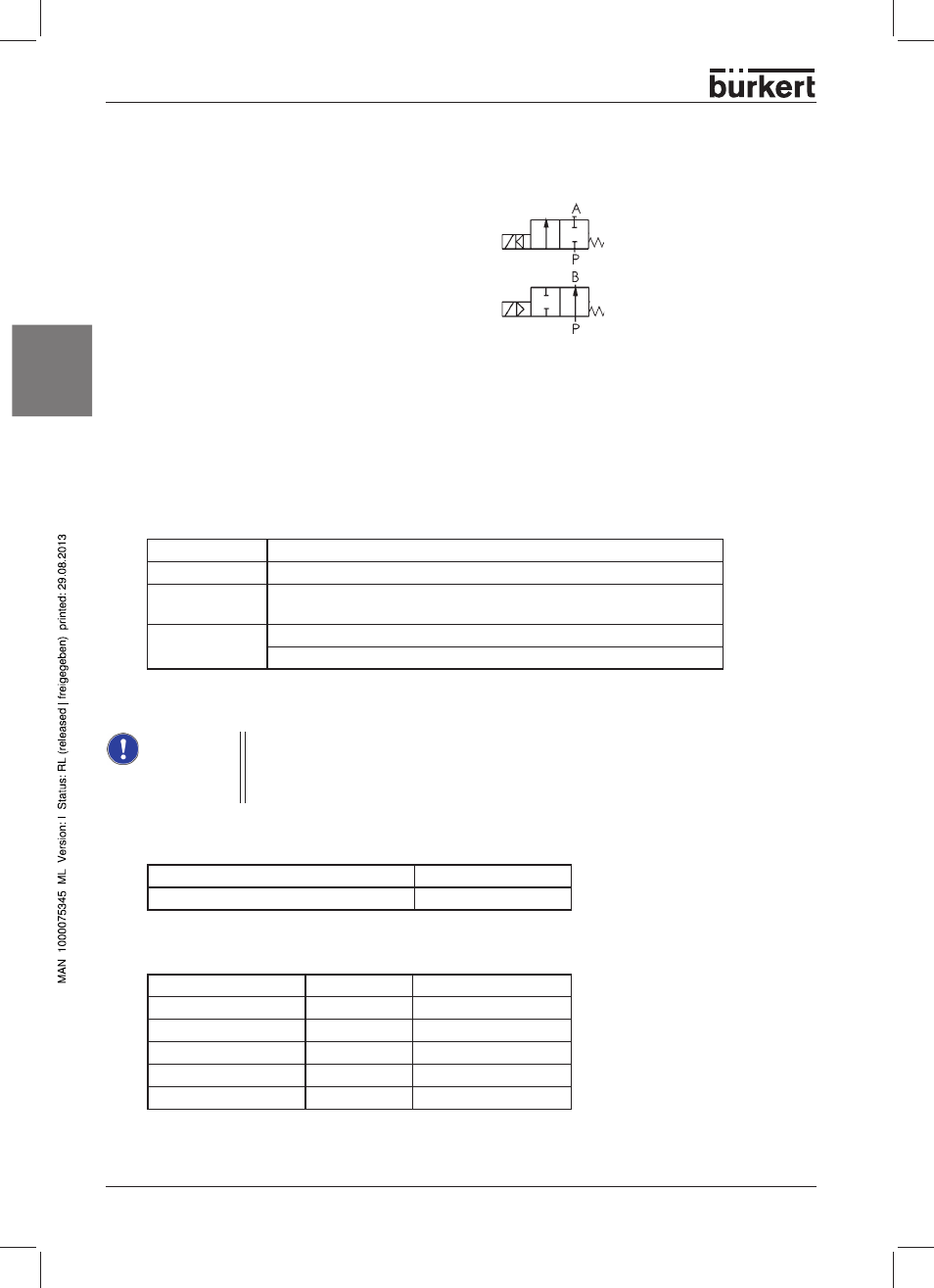

2/2-way piston actuated valve with control plug and angle seat body

Control function A (closed by spring force)

Normally close

Control function B (open in rest position)

Normally open

Actuator material:

PA (polyamide) or PPS

Body material:

stainless steel 316L

Seal materials:

steel/steel (1.4571) or PTFE/steel

MEDIA

Liquid and gaseous media that do not attack the body and seal materials.

Actuator size 80 (F)

5.5 - 10 bar

Actuator size 100 (G)

5.5 - 7 bar

Pilot pressure

Actuator size F

DN 15

0 - 16 bar

Actuator size F

DN 20

0 - 16 bar

Actuator size F

DN 25

0 - 16 bar

Actuator size F

DN 32

0 - 15 bar

Actuator size G

DN 40

0 - 12,5 bar

Actuator size G

DN 50

0 - 7,2 bar

Fluid pressure

NOTE

The permitted operating pressure and temperature of the medium are listed on the rating

plate and in the following tables. With regard to the permissible seat leakage, the values

given in DIN EN 1349 are complied with,whereby for the steel/steel seal, leakage class IV

and for the PTFE/steel leakage class VI apply.

Control medium

Quality classes according to DIN ISO 8573-1

Dust content

Class 5: Max. particle size 40 µm; max. particle density 10 mg/m

3

Water content

Class 3: Max. pressure dew point -20 °C or min. 10 degrees below the

lowest operating temperature

Oil content

Class 5: Max. 25 mg/m

3

in conjunction with Bürkert positioners

Class 3: Max. 1 mg/m

3

in conjunction with SIDE Control Type 8635

Note: Higher demands placed on the positioner must be observed!