Burkert Type 2105 User Manual

Page 13

13

Installation

8.3.3

installation of the actuator (welded body)

Installation for actuator with control function a:

notiCe!

damage to the diaphragm or the seat contour!

▶ When installing the actuator, ensure that the valve is in open

position.

→

Control function A pressurize the pilot air port 1 with compressed

air (5 bar): valve opens.

→

Lightly cross-tighten the body screws until the diaphragm is

between the body and actuator. do not tighten the screws yet.

→

Actuate the diaphragm valve twice.

→

Without pressurization tighten the body screws to the permitted

tightening torque (see following table “Tab. 1”).

Installation for actuator with control functions B and I:

→

Lightly cross-tighten the body screws without pressurization until

the diaphragm is between the body and actuator.

do not tighten the screws yet.

→

Pressurize pilot air port 1 of the actuator with compressed air

(5 bar).

→

Actuate the diaphragm valve twice.

→

Tighten the body screws to the permitted tightening torque (see

“Tab. 1”).

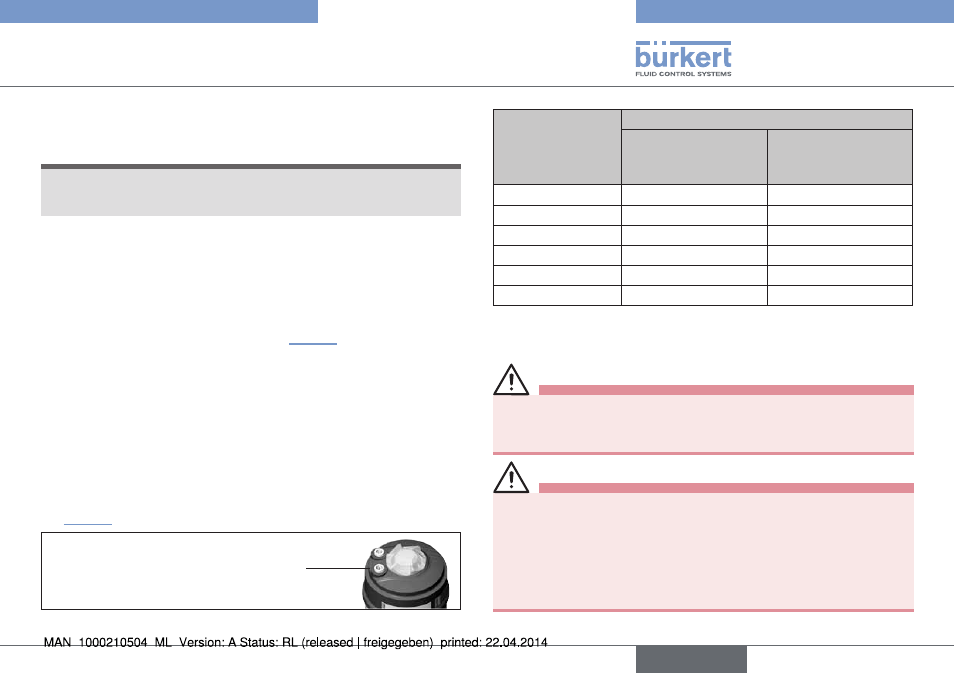

1

Pilot air port

CFA, CFB, CFI

Fig. 9:

Pilot air port

orifice dn

(diaphragm size)

[mm]

tightening torques for diaphragms [nm]

epdm/fkm

ptfe / advanced

ptfe / laminated

advanced ptfe

8

2.5

2.5

15

3.5

4

20

4

4.5

25

5

6

40

8

10

50

12

15

Tab. 1: Tightening torques for diaphragms

8.4 pneumatic connection

Danger!

danger – high pressure in the equipment!

▶ Before loosening the lines and valves, turn off the pressure and

vent the lines.

Warning!

risk of injury from unsuitable connection hoses!

Hoses which cannot withstand the pressure and temperature range

may result in hazardous situations.

▶ Use only hoses which are authorised for the indicated pressure

and temperature range.

▶ Observe the data sheet specifications from the hose manufacturers.

english

Type 2103, 2104, 2105