Burkert Type 2105 User Manual

Page 11

11

Installation

α

Angle α: 10° – 40°

Inclination to the line axis 1° – 5°

Mark

Fig. 6:

Installation position for self-drainage of the body

8.2.3

installation position T-valve type 2104

For the installation of the T-valves into circular pipelines, we recommend

the following installation positions:

When media is supplied:

When media is removed:

Fig. 7:

Installation position type 2104

8.2.4

installation position tank bottom valve

type 2105

Preferably with the actuator to the bottom.

8.2.5

preparatory work

→

Clean pipelines (sealing material, swarf, etc.).

→

Support and align pipelines.

remove the actuator from the valve body:

notiCe!

damage to the diaphragm or the seat contour!

▶ When removing the actuator, ensure that the valve is in open

position.

→

Control function A pressurize the pilot air port 1 with compressed

air (5 bar): valve opens.

→

Remove actuator with diaphragm by loosening the body screws.

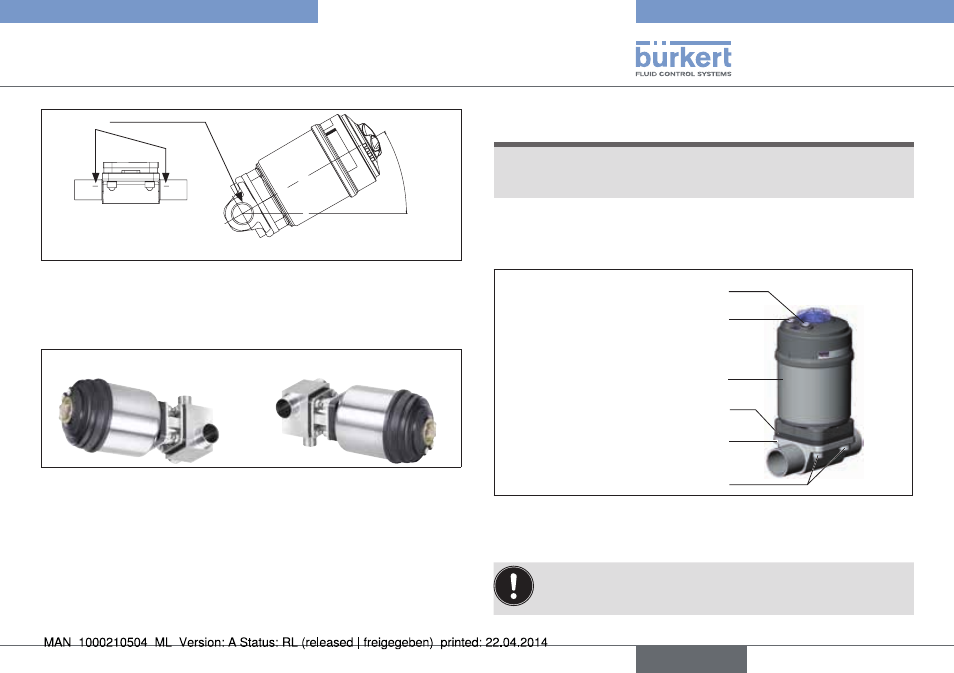

Actuator

Valve body

Air discharge connection CFA, CFB

Pilot air port CFI

Pilot air port CFA, CFB, CFI

2

1

Body screws (4x)

Diaphragm

Fig. 8:

Installation

8.3 installation

If used in an aggressive environment, we recommend con-

veying all free pneumatic connections into a neutral atmo-

sphere with the aid of a pneumatic hose.

english

Type 2103, 2104, 2105