Electrical connection, 7 installation and commissioning – Burkert Type 0641 User Manual

Page 12

12

Installation and Commissioning

6.2 Electrical connection

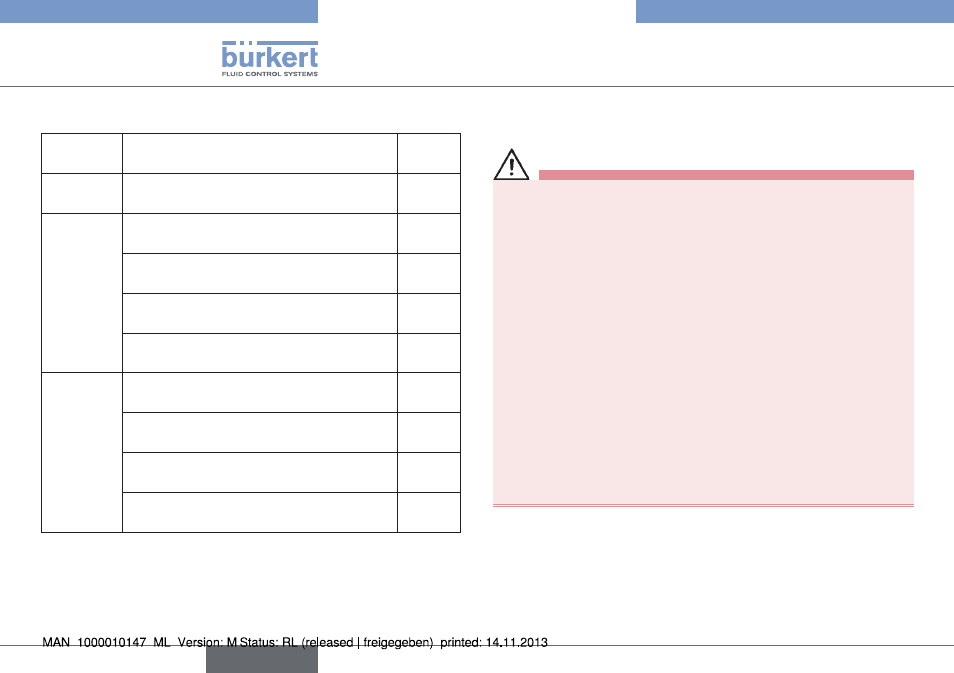

Marking

Execution

Internal

code

A *

Permanently installed rubber sheathed

cable of Type H05 RN-F3G0.75

none

L

** Terminal box with cable bushing

M20 x 1.5, without fuse

JA02

Terminal box with threaded nipple

M20 x 1.5, without fuse

JA08

Terminal box with threaded nipple

NPT 1/2, without fuse

JA09

Terminal box with threaded nipple

G 1/2, without fuse

JA10

K ***

** Terminal box with cable bushing

M20 x 1.5 and fuse

JA01

Terminal box with threaded nipple

M20 x 1.5 and fuse

JA05

Terminal box with threaded nipple

NPT 1/2 and fuse

JA06

Terminal box with threaded nipple

G 1/2 and fuse

JA07

* The connecting cable of solenoid Type 64..-, 65..- must be laid

permanently such that it is adequately protected from mechanical damage.

** Cable bushing to separate Design Inspection Certificate.

*** Fuse/contactor to separate Design Inspection Certificate.

7

INSTALLATION AND

COMMISSIONING

DANGER!

Danger of explosion!

▶ The device is a sealed system. The unit must not be dismantled!

The following safety regulations must be observed:

▶ The surface of the device may develop an electrostatic charge.

▶ In areas with an explosion hazard, the surface of the units may

only be cleaned with a damp cloth!

▶ Only permanently laid cables and wiring may be inserted.

▶ The operator must provide suitable stress relief.

▶ Wires with an outside diameter of 6 mm ... 13 mm may be used.

Observe the maximum thermal loading of the cables or wires to

be inserted.

▶ The inserted break-off seal must be matched to the diameter of

the cable or wire.

▶ The rated cross-section of the cable or wire strands must be at

least 0.75 mm² and may not exceed 2.5 mm².

▶ The screws for fixing the cover of the terminal box must be tight-

ened with a torque of 100 Ncm (±5%).

english

PTB 02 ATEX 2094 X