Burkert Type 0333 User Manual

Page 4

8

5.6 electrical data

Connections

DIN EN 175301-803 (DIN 43 650), shape A for

cable plug Type 2508 or 2509

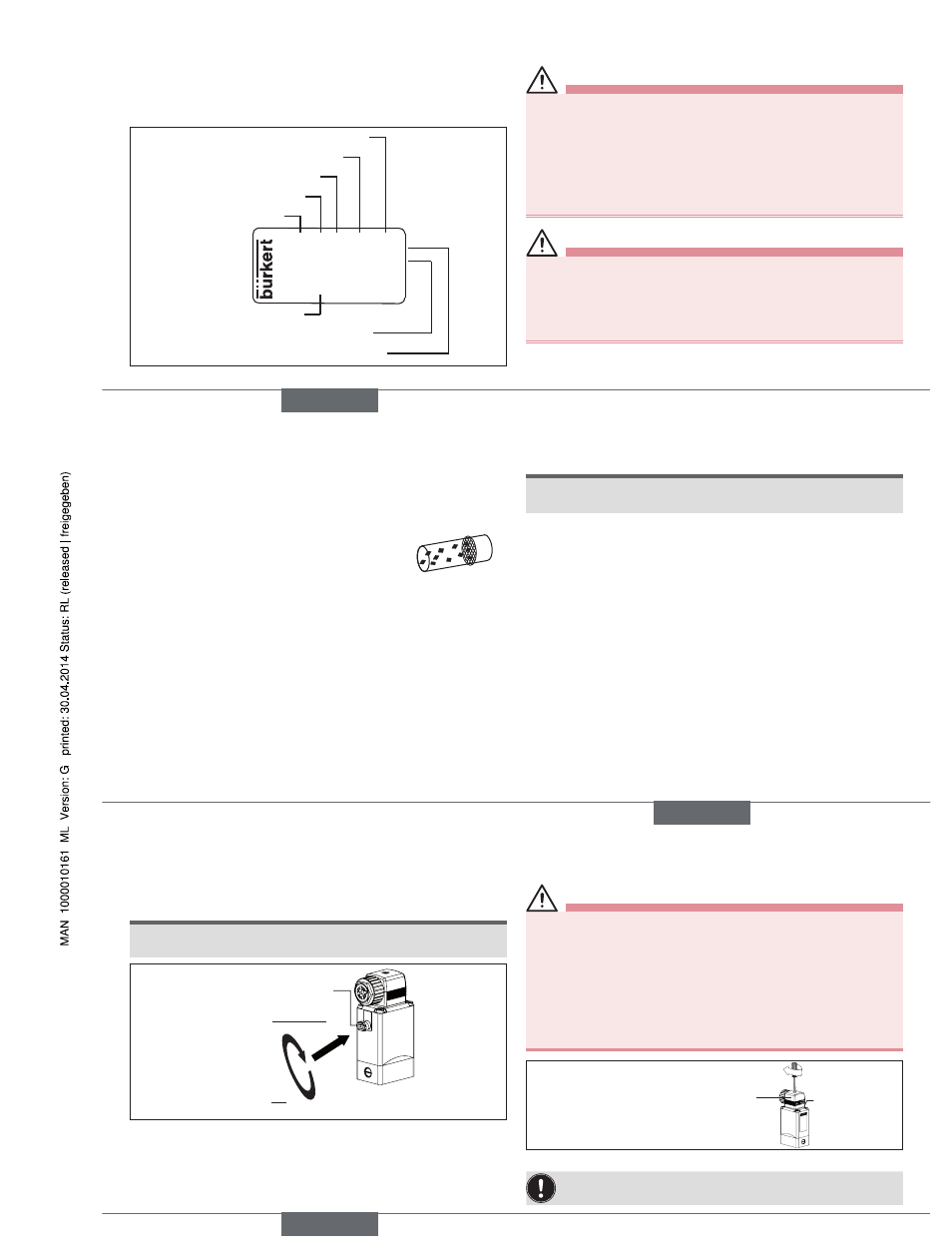

5.7 Type label

Made in Germany

00450000

W14UN

CE

0330 C 2.0 FKM MS

G1/4 0-6 bar

24V DC 8W

Identification number

Voltage, frequency, output

Port connection, nominal pressure

Type

Circuit function

Orifice

Sealing material

Body material

Fig. 1:

Description of the type label (example)

6

assemBly

Danger!

Risk of injury from high pressure in the system/device.

▶ Before working on the system or device, switch off the pressure

and vent/drain lines.

Risk of injury due to electrical shock.

▶ Before working on the system or device, switch off the power sup-

ply and secure to prevent reactivation.

▶ Observe applicable accident prevention and safety regulations for

electrical equipment.

WarnIng!

Risk of injury from improper assembly.

▶ The assembly may be carried out only by trained technicians and

with the appropriate tools.

▶ Secure system against unintentional activation.

▶ Following assembly, ensure a controlled restart.

english

9

6.1 Before installation

Installation position:

The installation position is optional. Preferably: Actuator at the top.

→

Prior to installation check pipelines for dirt and clean if necessary.

Dirt filter: To ensure that the solenoid valve func-

tions reliably, a dirt filter (

≤ 500 µm) must be

installed in front of the valve input.

6.2 installation

→

Observe flow direction:

Functioning of the device is only ensured if the circuit function is

maintained.

Devices in socket model

→

Use PTFE tape as sealing material.

→

Determine the maximum screw-in depth of the connecting threads

as this does not comply with any standard.

note!

Caution risk of breakage.

▶ Do not use the coil as a lifting arm.

→

Hold the device with a suitable tool (open-end wrench) on the

body; screw into the pipeline.

Attaching the device:

→

Via bore holes M4x8 (made from brass or stainless steel) or self-

tapping screws 3.9 DIN 7970 (made from plastic, max. screw-in

depth 10 mm) on the bottom side of the body at drill pattern

38x24.

Devices in flange model

Attaching the device:

→

Via supplied screws on basic devices or manifold.

→

Tighten fastening screws on the coil to a maximum torque of 2 Nm.

english

10

6.3 manual control

note!

▶ When the manual control is locked, the valve cannot be actuated

electrically.

1

2

Press

Turn

Manual control

Fig. 2:

Manual control

7

elecTrical connecTion

Danger!

Risk of injury due to electrical shock.

▶ Before working on the system or device, switch off the power sup-

ply and secure to prevent reactivation.

▶ Observe applicable accident prevention and safety regulations for

electrical equipment.

If the protective conductor is not connected, there is a risk of

electric shock.

▶ Always connect protective conductor and check electrical continuity

between coil and housing.

Approved cable plug, e.g. Type

2508 or other suitable cable plug

in accordance with

DIN EN 175301-803 shape A

max. 1 Nm

Seal

Fig. 3:

Connecting the cable plug to the power supply

Note the voltage and current type as specified on the type label.

english

Type 0121 / 0330 / 0331