Brooks, Model 5851 i – Brooks Instrument 5851i User Manual

Page 32

4-4

Installation and Operation Manual

X-TMF-5851i-MFC-eng

Part Number: 541B109AAG

September, 2009

Brooks

®

Model 5851

i

Section 4 Maintenance

& Troubleshooting

Table 4-1 lists possible malfunctions which may be encountered during

bench troubleshooting.

C. Sensor Troubleshooting

The sensor tube is part of a calibrated flow divider that is designed to

operate within a preset gas flow range. The sensor assembly may be

removed or replaced by referring to Section 4-4, Disassembly and

Assembly. If the sensor assembly is cleaned and reinstalled, a calibration

check should be performed. Refer to Section 3-4.

NOTE: Do not attempt to disassemble the sensor.

D. Cleaning Procedures

Should the Model 5851

i Mass Flow Controller require cleaning due to

deposition, use the following procedures:

1. Remove the unit from the system.

2. Refer to Section 4-4 to disassemble the controller.

3. Use a hemostat or tweezers to push a 0.007" diameter piano wire

through the flow sensor tube to remove any contamination. For best

results, push the wire into the downstream opening of the sensor tube

(end closest to the control valve). The sensor tube can be flushed with

a non-residuous solvent or DI water. A hypodermic needle filled with

solvent is a convenient means to accomplish this.

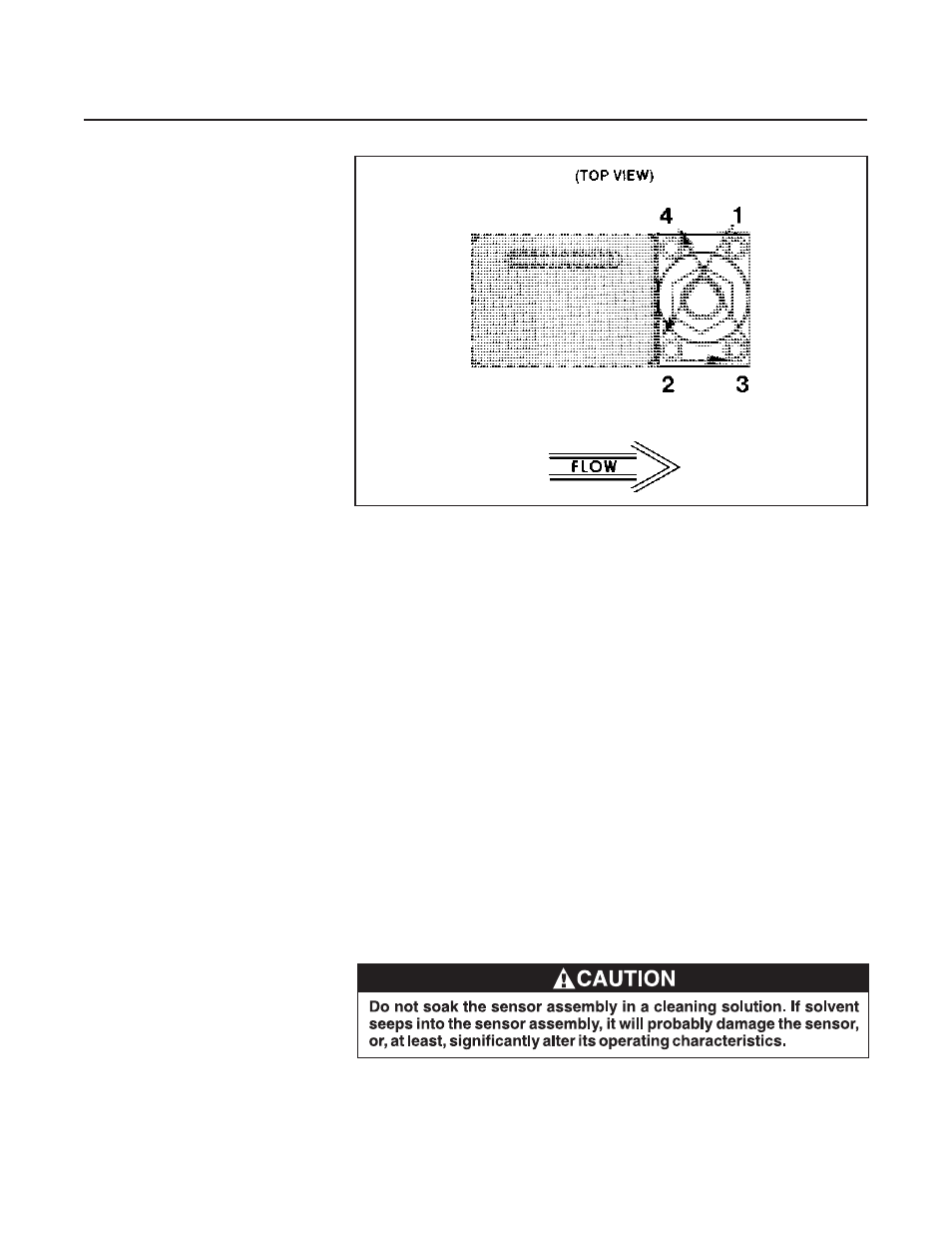

Figure 4-1 Torque Sequence for the Valve Retainer Plate