Brooks, Model 5851 i – Brooks Instrument 5851i User Manual

Page 27

3-9

Installation and Operation Manual

X-TMF-5851i-MFC-eng

Part Number: 541B109AAG

September, 2009

Brooks

®

Model 5851

i

Section 3 Operation

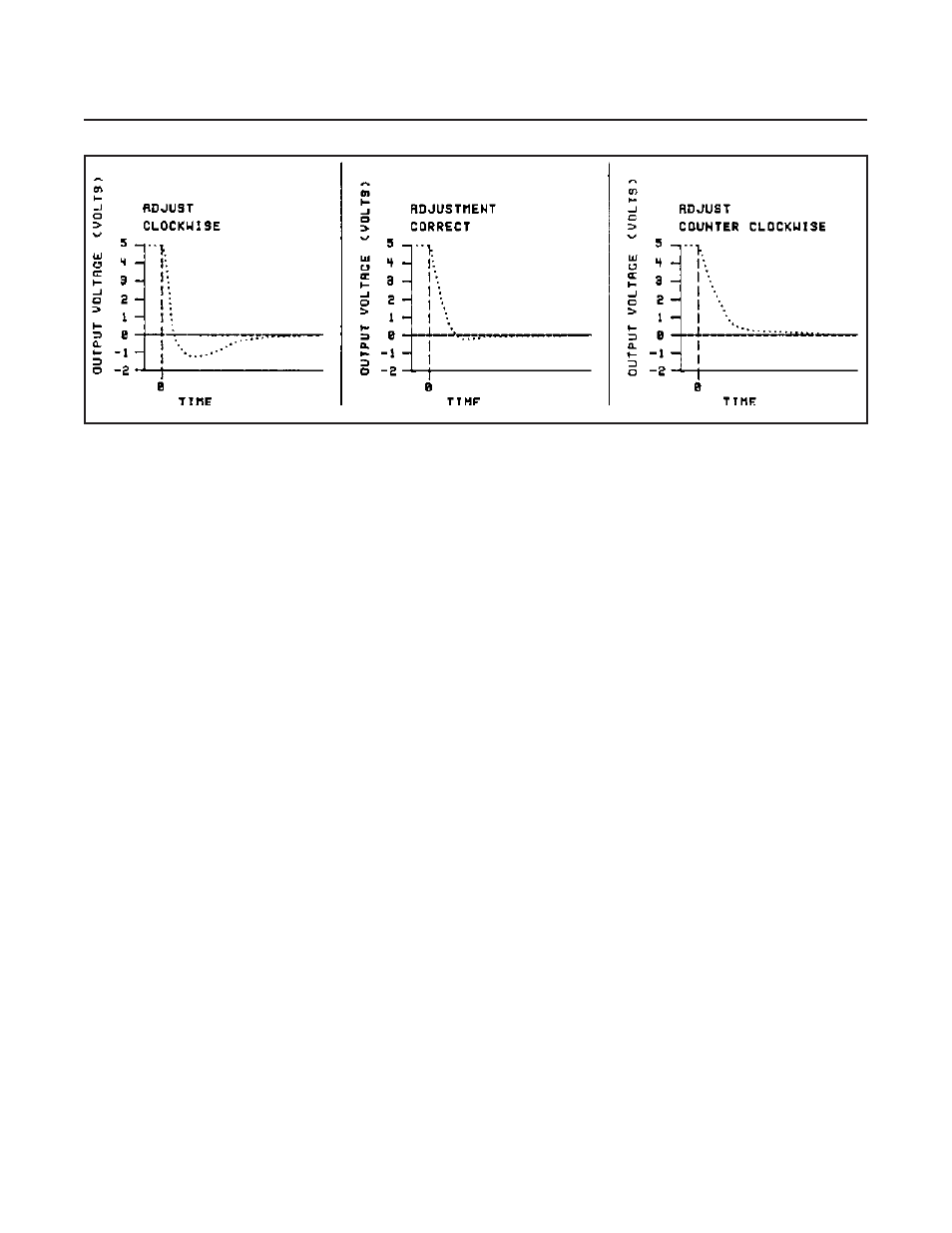

Figure 3-6 Fast Response Adjustment

a. Set the command potentiometer for 100% flow (5.00V) and wait

about 45 seconds for the flow output signal to stabilize.

b. Step the command signal to 0% or activate valve override closed to

stop the flow. Observe the flow signal output as it decays.

c. The behavior of the flow signal during this transition between 100%

and 0% flow indicates the adjustment required of the anticipate

potentiometer. Refer to Figure 3-6.

d. If the flow signal measured on pin 2 decays to -0.05 to -0.5V, then

rises to 0V, the anticipate potentiometer is properly adjusted.

e. If the flow signal decays rapidly and goes below -0.5V before rising to

0 V, the anticipate potentiometer must be adjusted clockwise and

steps a and b repeated.

f. If the flow signal decays slowly and does not go below -0.05 V, the

anticipate potentiometer must be adjusted counterclockwise and

steps a and b repeated.

2. Fast response adjustment (six second response specification

guaranteed)

Adjustment of the anticipate potentiometer to obtain a flow rate

performance to be within 2% of flow rate commanded in less than six

seconds after setpoint change requires the use of a fast response

flowmeter (500 millisecond response to be within 0.2% of final value or

better) in series with the 5851i and a storage oscilloscope or recorder.

a. Allow the flow controller to stabilize at 0% setpoint for at least thirty

seconds. Make a step in setpoint to the controller from 0-100% of

full scale flow and record the output signal of the fast response

flowmeter.

b. If this signal shows more than 4% overshoot, adjust the anticipate

potentiometer one-half to one turn counterclockwise. If the signal

does not show overshoot but is not within 2% full scale of final value

after six seconds, adjust the anticipate potentiometer one-half to one

turn clockwise. Set command potentiometer for 0% of flow.

c. Repeat steps a and b until the fast response flowmeter output signal

meets the specified response requirements.

NOTE: With the above equipment, the anticipate potentiometer can be

adjusted to give optimum response characteristics for any process.