Installation and operation manual – Brooks Instrument QMBM User Manual

Page 16

QmB Series IP40, IP66, IP66XP

Section 1 Introduction

1-4

Installation and Operation Manual

X-CM-QmB-eng

Part Number: 541B029AAG

June, 2011

Repeatability

(7)

:

± 0.05% or ± [0.5 x (zero stability/flowrate) x 100]% of rate whichever is greater

Device Leak Integrity

(8)

:

Elastomer Sealed Device: Outboard 1 x 10

-9

atm. cc/sec., helium (maximum)

Metal Sealed Device: 1 x 10

-10

atm. cc/sec., helium (maximum)

Turn Down:

Controller: 100:1 or down to the minimum measurable flow, whichever flow rate is greater

Meter: to minimum measurable flow

Settling Time:

Controller (Stainless Steel sensor tube): Less than 2 seconds within 2 % full scale of final

value, ± [(zero stability/flowrate) x 100]% of rate per SEMI Guideline E17-91

Controller (Hastelloy sensor tube): Less than 12 seconds within 2 % full scale of final

value per SEMI Guideline E17-91

Meter: Less than 0.5 seconds within 2 % full scale of final value, ± [(zero stability/flowrate)

x 100]% of rate per SEMI Guideline E17-91

Maximum Operating Pressure

(8)

:

Standard: 3.5 MPa, 35 bar or 500 psi

Optional: 10 MPa, 100 bar or 1500 psi

Optional: 30 MPa, 300 bar or 4500 psi (Hastelloy sensor tube only)

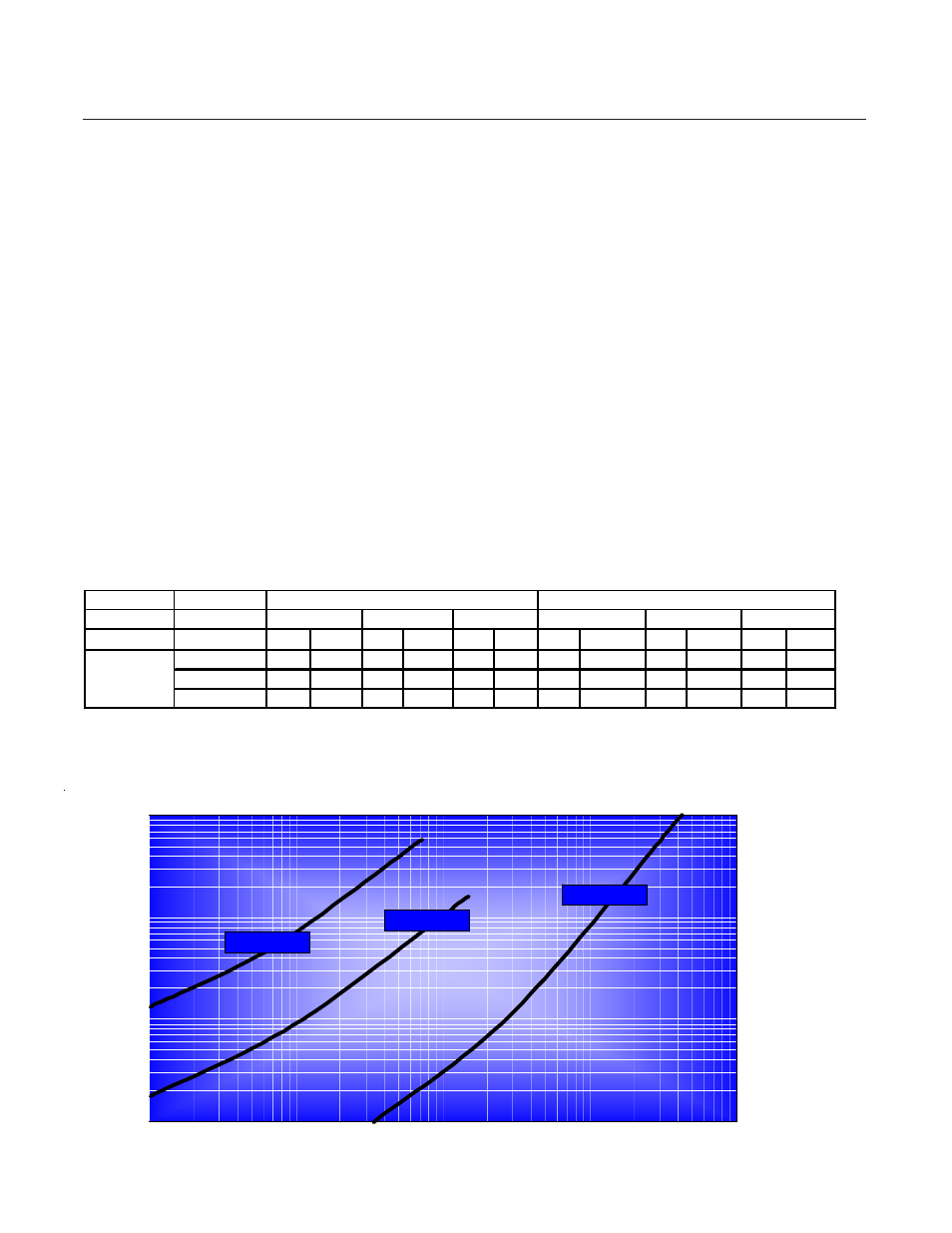

0.1

1.0

10.0

100.0

10

100

1,000

10,000

100,000

Mass Flow (grams/hr)

Pressu

re Drop (psi)

Tube Size 2

Tube Size 3

Tube Size 4

Differential Pressures , Meter

(9)

Pressure Drop Liquid - (H

2

0)

Differential Pressure Requirements, Controller

(9)

:

Liquid

Gas

Quantim

Quantim

KpA

bar

psi

KpA

bar

psi

Model

(1)

Tube Size

min

max* min max* min max* min

max*

min

max*

min

max*

2

69

1034

0.7

10.3

10

150

69

1724

0.7

17.2

10

250

QMBC

3

69

1379

0.7

13.8

10

200

69

1034

0.7

10.3

10

150

4

69

1379

0.7

13.8

10

200

69

1034

0.7

10.3

10

150

* Actual maximum pressure drop will depend on process conditions and orifice selection.