Bray 70 Series SERVO PRO User Manual

Page 21

19

BRAY Series 70 Servo Pro

Operation and Maintenance Manual

BRAY Series 70 Servo Pro

Operation and Maintenance Manual

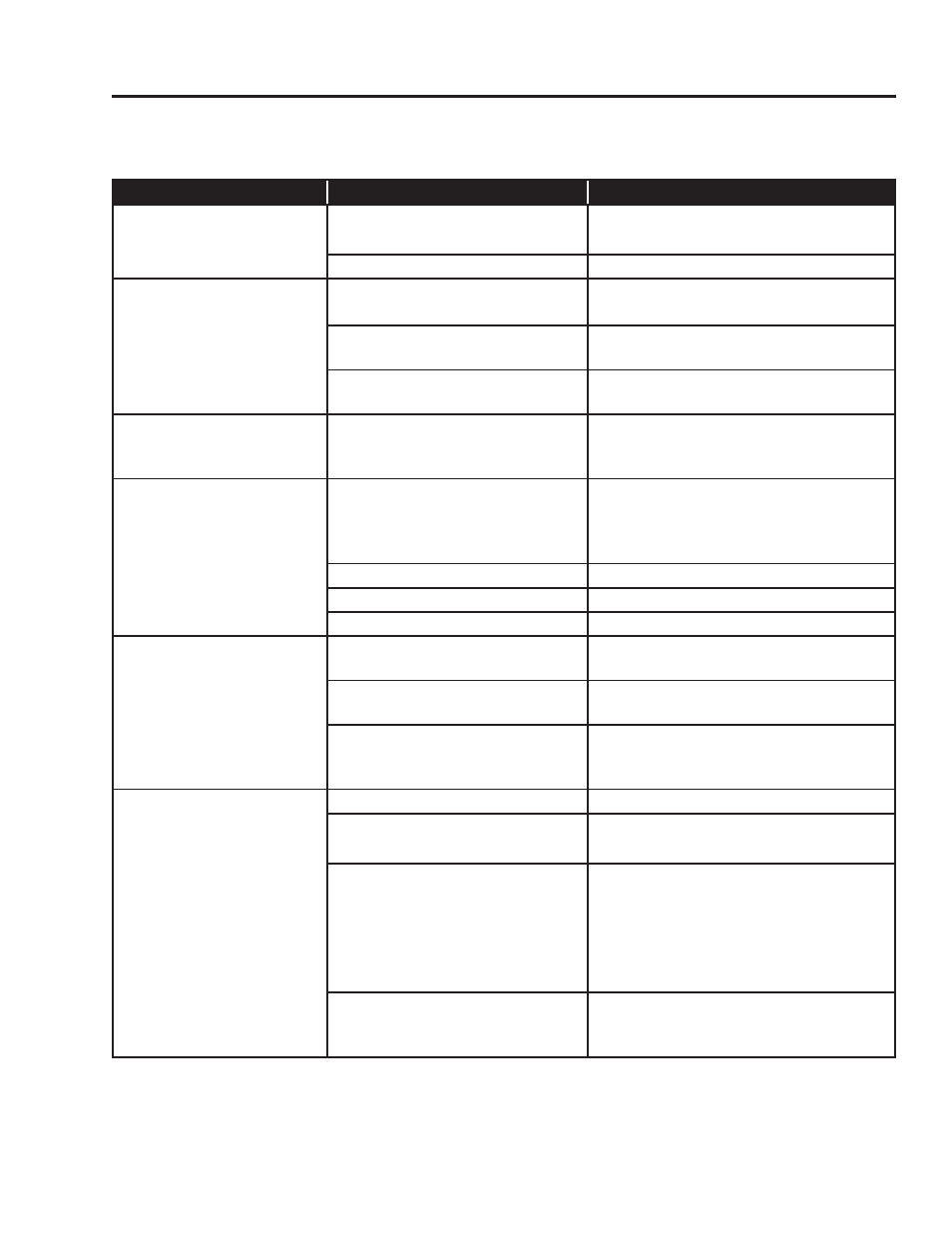

Problem

Possible Cause

Possible Solutions

Actuator moves back and

forth near setpoint (hunts)

Signal is fluctuating beyond the

deadband setting

Increase the deadband using the

Deadband trim pot

Signal has interference

Shield signal from interference.

Actuator does not travel fully

open or fully closed

Travel limit switches are not

set correctly

Set travel limit switches for 90° operation

Servo DIP switches are not

set correctly

See Quick Setup Instructions on page 9.

Mechanical travel stops are not

set correctly

Set mechanical travel stops just outside

the electrical travel limit switch positions

Actuator motor does not run

in either direction and the

green Power LED is off

Power does not match Servo Pro

voltage and phase, fuse is missing

or blown, power is turned off

Verify fuse, verify power voltage and

phase, turn power on & recalibrate

Actuator motor does not run

in either direction and the

green Power LED is on

Limit switches or torque switches

are activated

Verify that the travel limit switches are

properly set; verify torque switches are

presents or set configuration to Torque

Switch Disabled

Handwheel is engaged

Push handwheel in (disengage)

Servo Pro is not wired correctly

Check all Servo Pro wiring

Motor has thermally tripped

Allow motor to cool down

Actuator does not

properly respond to a

command signal

Potentiometer gear is not engaged

or adjusted properly

Engage and adjust potentiometer gear

Command signal does not match

Configuration switches

Set the Configuration switches correctly

Command signal is faulty or wired

incorrectly

Verify the value of the command signal

with a meter and verify the wiring polarity

is correct.

Actuator runs in one

direction only

Wiring is incorrect

Correct Wiring

Potentiometer wired backwards

Reverse white and gray wires, see wiring

diagram inside cover

Limit switch or torque switch

is activated

Verify continuity between the wires coming

from the switches. If your actuator has

reached its travel limit, reverse direction.

If one of your torque switches has tripped,

reverse the actuator direction and correct

the over torque condition

Command signal is faulty or

wired incorrectly

Verify the value of the command signal

with a meter and verify the wiring polarity

is correct

6.2 t

roublesHooting

c

Hart