Atec EuroSMC-Mentor-12 User Manual

Page 11

11

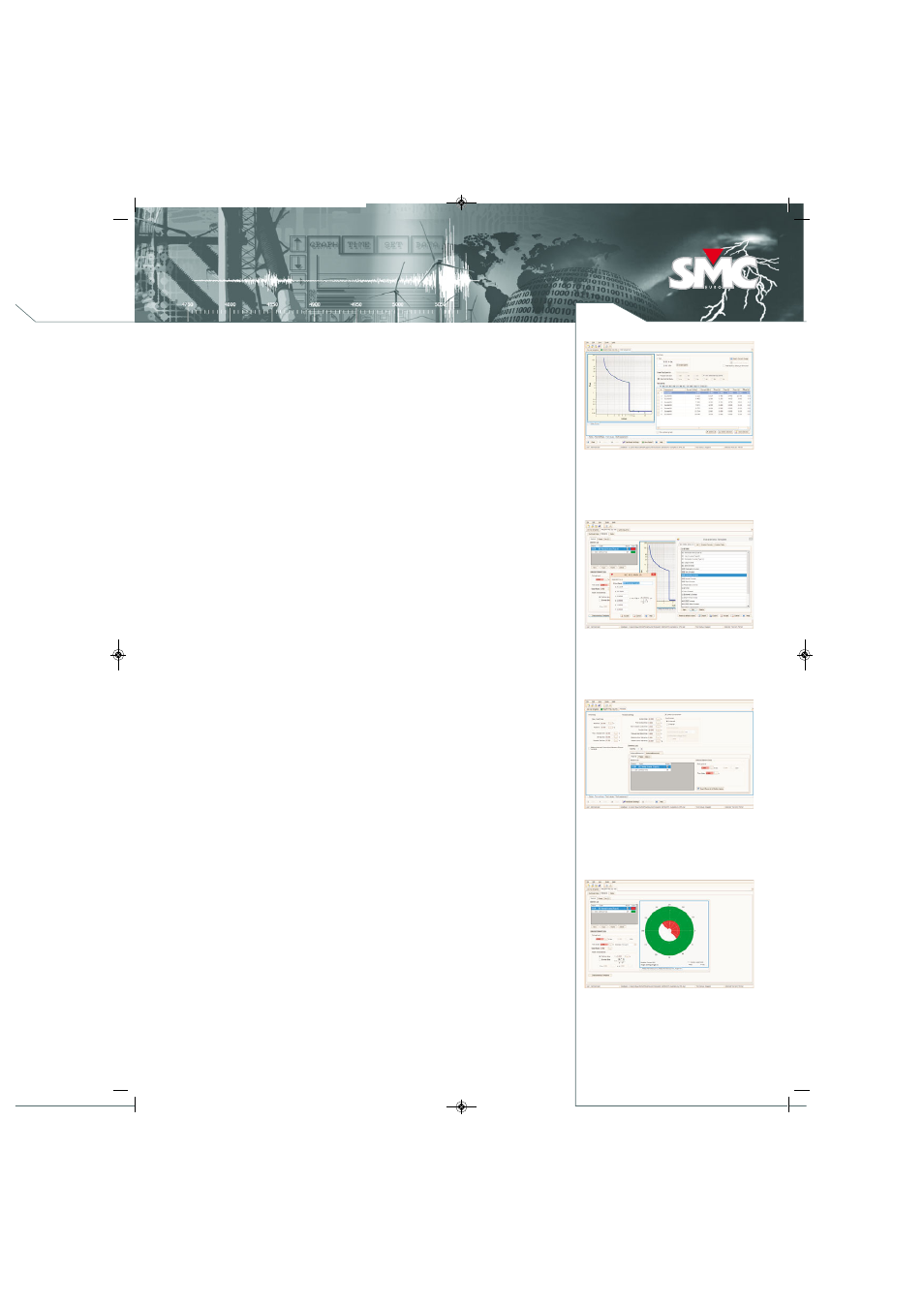

Click Sequence Test

Element list and characteristic templates

Test Settings

Angle View

OVERCURRENT MODULE

The Overcurrent test module is used to automatically test the performance of protective devices that

implement any combination of the 50, 50N, 51, 51N, 67, 67N, 46 and 49 protection functions. It includes

tests of operating values, and the external scheme tests related to these protective functions.

The module's functionality is distributed in the following sections, among others:

Technical data: general parameters that affect all the tests contained in the Overcurrent module, such

as: work with primary values, elements used for phase-ground faults, ground CT data, sensitive ground

CT data, Current, time and angle tolerances, directional settings, grounding characteristics and

transformer connection.

Element list: the test module supports any number of phase, neutral, negative sequence, ground and

sensitive ground elements. Different element characteristics can be selected, added and activated in

the Element List, and different settings can be adjusted for each one. A Graphical View of the Relay

curve is available for Non Directional and Directional Relays (Forward Curve, Reverse Curve and

Operation/No Operation zone view).

Characteristics Template: access to the edition of the different inverse time characteristics that

Roots contain. Groups of pre-defined Characteristics are available depending on specific equations

(IEC, IEEE, ANSI, U.S.), user-defined formulas, and curves in tabular form. Each one can be edited through

modification of the associated variables. The user can also easily create new curves from scratch.

Test Screen: with flexible access and configuration of the various test elements:

- Test Settings (prefault, fault and postfault).

- Test Points: table of test points for each Fault type loop with the set values. With several methods to

define and insert test points, individually, interactively clicked right onto the characteristic’s drawing

or a number of time-saving tools can be used to automatically generate series of test points,

supporting separate or multiple fault loops selection (A-N, B-N, C-N, A-B, ABC, etc).

- Test Result Assessment, automatic and manual.

- Test Graph of the protection element: For directional relays, the graph shows three views, relay curve

for forward and backward faults, and an angular view, indicating the operating area by colors.

- Phasor Graph: allow to view the phasor diagram of every point being tested.

- Hardware Settings: map the test set I/O and power connections to the relay, configuration of operating

options of the test set for Binary I/O (Relay/Open Collector, NO, NC, Dry/Voltage).

- Report and Report Configuration: automatic report generation with user selection of data to be shown.

The report can be produced in PDF format or other data interchange like XML. Reports are saved along

with the results in the database.

- Test execution: automatic sequential injection of test settings for every test point, comparing the operating

time measurement with the allowable current and time tolerances in technical data, assessing the

result as correct or incorrect and printing it both in the test point table and the test graph. The test

sequence can be stopped at any time by the operator, and then resumed from the first non-tested

point. The user may also decide to reset the tested points and restart the entire test from the

beginning, or to repeat the test only for a selection of the points in the list without affecting the other

test points.

Test List: Multiple tests can be selected and attached to the device under test from a wide choice of

test types including scheme-oriented tests like reclosing or CB failure:

- Click Sequence

- Pick up/drop out

- Reclose

- Cold Load

- SOTF (Switch On To Fault)

- I2/I1 Ratio

- Breaker Fail

- Fuse Failure

- SOL (Selective OC Logic)

- Reset Time

Mentor12 EN v3_SMC fichas 09/08/13 15:10 Página 11