Tsp-dms wiring – Franklin Fueling Systems TSP-DMS User Manual

Page 3

First Measure the height of the riser, measuring from the

top opening to the tank, make note of this length, and now

find the outside diameter of the tank. Add the riser length

to the diameter of the tank: this should be the total depth

from the interstitial opening to the bottom of the interstitial

shaft. Now you will need to subtract the length of the

sensor you are installing.

• The TSP- DMS-12 is 22”

The mark on the sensor wire needs to be:

Riser Length + Tank Diameter-Sensor Length

When lowering the sensor, the marked point should stop at

the top of the riser entrance confirming the sensor is at the

bottom of the interstitial space.

Slowly lower the TS-DMS down the shaft until the mark

made is near or at the opening of the interstitial shaft.

Feed the sensor wire through cap and compression

gland (purchased locally) making sure the sensor wire is

still slack indicating you have not pulled off the bottom.

Tighten compression gland. Do no tighten the cap down

at this time as the sensor will need to be tested once all

programing and learning has been completed. The sensor

is now ready to be wired and connected to the console.

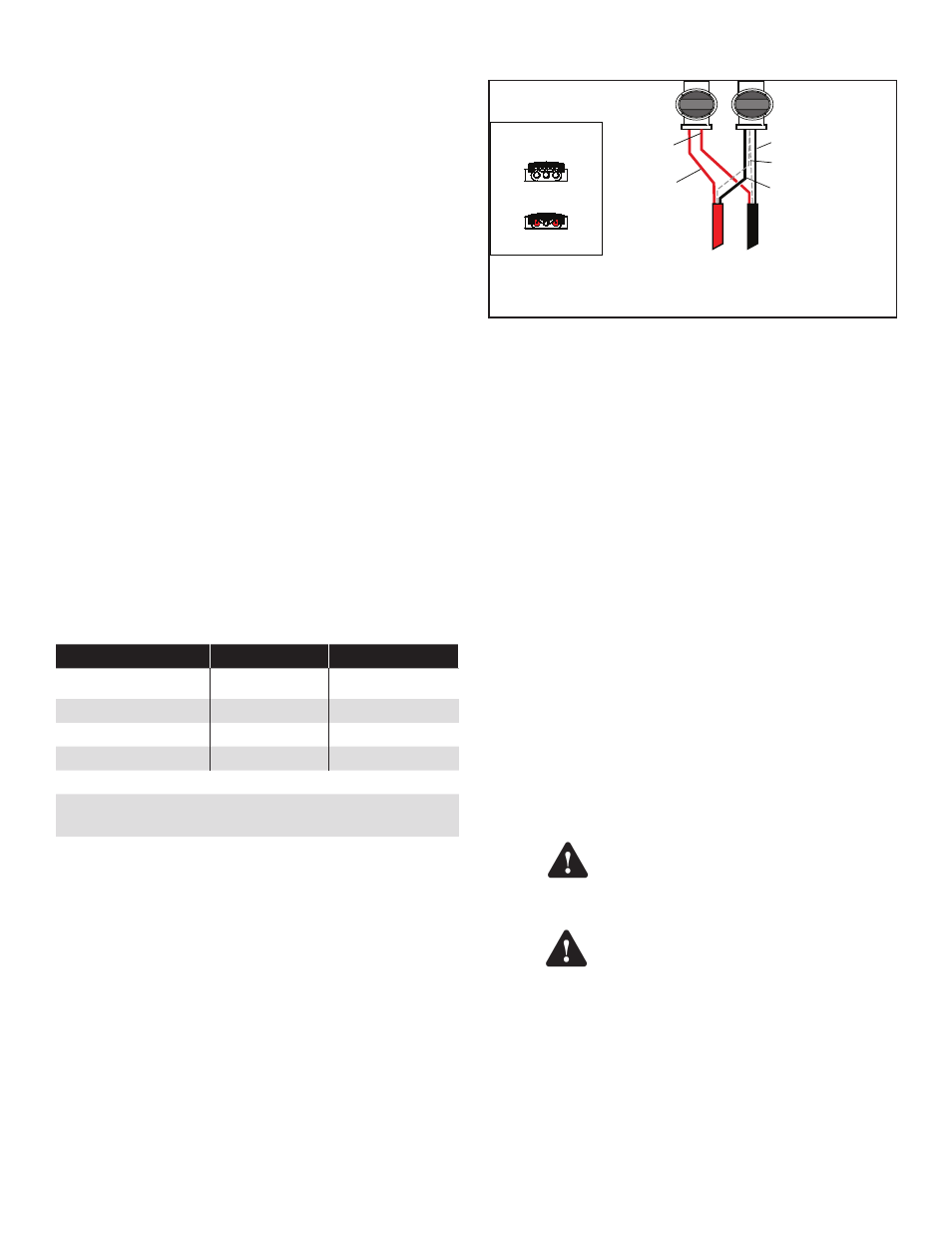

TSP-DMS Wiring

Use cables and wires compliant with national and local

codes. Franklin Fueling Systems recommends using

the types of cable list in Table 1 up to the recommended

lengths.

Cable Type

O.D.

Distance ft (M)

*

Belden No. 87760 0.12” (3 mm)

260 (80)

* Belden No. 87761 0.12” (3 mm)

400 (120)

*

Belden No. 88761 0.12” (3 mm)

400 (120)

* Belden No. 89182 0.31” (7.9 mm) 1500 (450)

* These cables can be ordered from INCON.

Use only cable as specified or equivalent to the above.

Do NOT exceed cable lengths of 1500 feet.

Table 1: Sensor Cables

WARNING: Use of sub-standard cables, or exceeding

maximum cable lengths may result in faulty operation, can

create an explosion hazard, and WILL void the warranty.

Conduit

The above-listed wiring is for use when run in Rigid Metal

Conduit. If local codes allow use of nonmetallic (PVC)

conduit, use Alpha Wire #58411 (INCON #600-0062).

Cable Color Code

Use the following color code for the sensor wiring:

RED or YELLOW WIRE = + (Signal)

BLACK WIRE = – (Signal Ground)

BARE = SHLD (Shield)

Label Cables

Label all sensor cables within the weatherproof pull box,

and at the console with the Tank / Sensor number.

After Crimp

To

Console

To

TSP-DMS sensor

Before Crimp

End view of splice

Black wire of sensor

Both shield wires

Red wire of

field cable

Black wire of

field cable

Red wire

of sensor

Connect bare metal shielding together

Figure 4: Model TSP-DMS — Cable Wire Splicing

Splice the sensor cables together at the weatherproof

junction box located in the manhole as shown in Figure 4.

Black wires from sensor and console are spliced together

with the shield (bare) from both.

Red wires from sensor and console are spliced together.

If a white wire is present on the sensor cable, cut it back.

Use the No-Strip Electrical connectors supplied in the

installation kit to make all connections.

Note: Do not use wire nuts to make sensor connections.

Use the crimp splice connectors supplied with the TSP-

DMS, or equivalent, only. Failure to use the appropriate

crimp-splice connectors will result in faulty operation and

will void the warranty.

Note: Avoid wiring errors by using consistent color codes

when making sensor cable connections. Always

use the Red (or yellow) wire for the + signal. Always

use the Black wire for – signal ground. And always

use the bare wire as the shield.

Note: Make sure that all conduits, conduit fittings, junction

box fittings and hole plug threads are waterproofed

with pipe-dope. Wet wiring will result in faulty

operation.

Make sure that the sensor cable is

wired correctly. Reversing the plus

and minus terminals can damage the

Intrinsically Safe circuits.

Only one sensor should be connected

per channel. Connecting multiple

sensors to a single cable or channel in

the FMS console may cause damage to

the unit and may create an explosion

hazard, and will result in improper

system operation.

Warning

Caution