Overview, Materials required, Installation sequence – Franklin Fueling Systems TSP-DVS User Manual

Page 2

Overview

The TSP-DVS sensor is an intelligent BriteSensor ® that

is used to detect the presence of hydrocarbon vapors

(product). The sensors are installed suspended above

the highest recorded ground water table (level) in 4 or

2 inch monitoring wells around tanks. The sensors use

intrinsically safe (I.S) leak detection circuits and are rated

for use in Class 1, Division 1, Group D Hazardous Areas.

Three types of sensors are integrated in the TSP-DVS: a

vapor sensor to detect hydrocarbon vapors, conductivity

electrodes to detect water (submerged sensors can’t

detect product vapors), and a temperature sensor (to help

minimize false alarms).

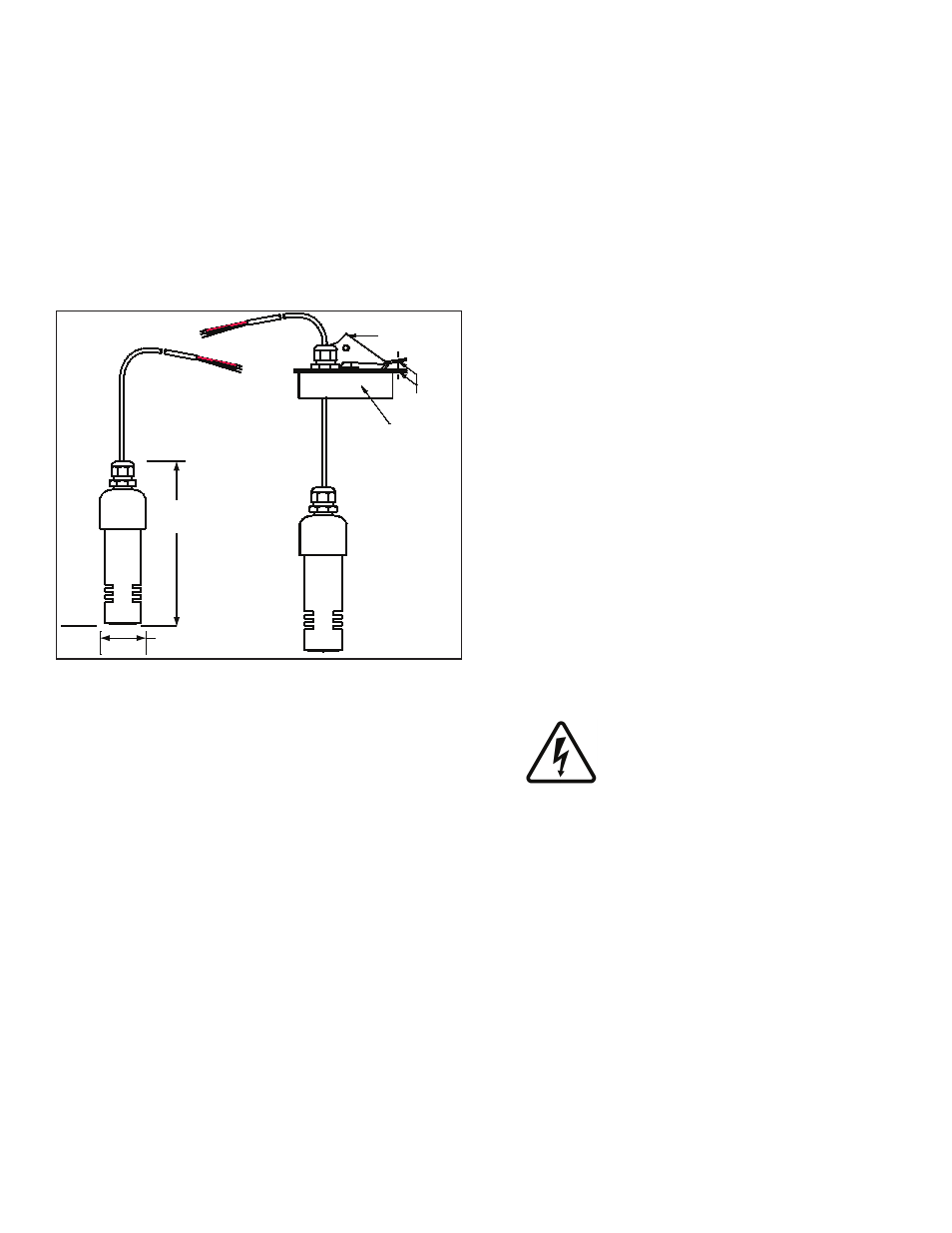

Datum

6.00 inch

(152.4 mm) Ref.

1.63 inch (41.4 mm)

Max. dia. Ref.

TSP-DVS

Discriminating monitoring

well vapor sensor

(Britesensor)®

Locking riser cap:

TSP-KW4

4 inch (102 mm)

or

TSP-K12

2 inch (51 mm)

Lever

Thru holes

for locking

Figure 1: TSP-DVS Sensor Dimensions

Like other BriteSensors, the TSP-DVS sensors have a

microprocessor that analyze the environmental conditions

at the sensor and transmits this data to the Automatic

Tank Gauge console. TSP-DVS sensors detect and

communicate: a WATER alarm (from the conductivity

sensors), VAPOR present (from vapor & temperature

sensors), and a NORMAL no-alarm state (hydrocarbon

vapors are not present and sensor is not in water), plus it

transmits a specific sensor ID code.

No-strip electrical wire connectors, 25 feet of cable

attached to the sensor, a Model ID tag, and a cord-

grip fitting (for connection to a weatherproof electrical

junction box) are supplied with the TSP-DVS sensor (see

diagrams).

Materials Required

• Optional – TSP-DB1 epoxy seal kit for no-strip electrical

connectors – recommended for sites: within flood zones,

high groundwater tables, with poor drainage, or when

junction boxes are not used.

• Monitoring well screen pipe (perforated / slotted) –

Schedule 40 PVC, 4 inch (102 mm) diameter, OR 2 inch

(50.8 mm) diameter.

• Riser Cap – TSP-KW4 for 4 inch dia. monitoring well

screen pipe or TSP-KI2 for 2 inch dia. monitoring well

screen pipe.

• ½ or ¾ inch NPT (National Pipe Thread, tapered), Rigid

Metal Conduit (RMC) or nonmetallic (PVC) conduit if

allowed by local code.

• EYS Seal fittings and epoxy to fill the fitting after

operational testing is completed.

• Weatherproof junction box, gasket, and cover, plus a

3/4 to 1/2 inch NPT reducing bushing if 1/2 inch RMC is

used – see the ATG Installation Guide for recommended

electrical junction boxes.

• Wire: THHN, TFFN or THWN, 18 AWG: Red, White, &

Black, or Alpha Cable # 58113, 0.131 (3.3 mm) O.D. –

1,500 feet (457 meters) max. length. Alpha Wire #58113

must be used if using nonmetallic (PVC) conduit.

• Slip joint pliers to seat the no-strip, self-sealing wire

connectors – connectors are supplied with the sensor.

• U.L. classified thread sealant or pipe dope.

Installation Sequence

1. Install sump.

2. Install conduit, EYS fittings, and weatherproof

junction box.

3. Shut off power.

ELECTRICAL DANGER Avoid electrical

shock hazards: ensure all power

going to the ATG console is turned off,

tagged, and locked-out at the power

panel before doing any maintenance or

installation work at the ATG console.

4. Install the sensor cable through the supplied

compression fitting.

5. Install the compression fitting at the waterproof

junction box and tighten the cord-grip fitting.

NOTE Do not cut / trim the sensor cable because it must

be removed and tested occasionally outside in the

open air (coil up cable).

6. Trim wire / cables at the junction box to a 6 or 8

inch length (15 or 20 cm) or service-loop, and

splice the sensor and console wires together per

Figure 3. Before pulling wires, mark them to avoid

confusion when connecting to the ATG.

7. Turn power on to console to test sensor.

2