Product description, Installation in a dispenser – Franklin Fueling Systems DC406 Dispensing Cutoff System User Manual

Page 3

3

Product Description

The DC400 system uses a sump sensor (latching float

sensor or non-latching optical sensor) to detect the

presence of liquid in the STP (Submersible Turbine Pump)

or dispenser sump. If liquid is detected, the system will

shut down power to the STP or dispenser.

Installation in a Dispenser

Unpack unit and check for shipping damage. The system

consists of two components, the controller and the sensor.

1. Shut off the power to the dispenser:

Remove power to avoid possible

electrocution or ignition of explosive

gasoline vapors.

2. Remove the cover from the junction box and

locate a spare threaded hub.

3. Remove the plug from the hub and if needed

install a reducing bushing so that you have a ½”

threaded opening.

4. The controller has 7 wires extending from the

end of a ½" nipple. Feed the 7 wires through this

opening and thread the ½" nipple into a hub.

5. Tighten the nipple using a wrench on the nipple

and not the body of the controller.

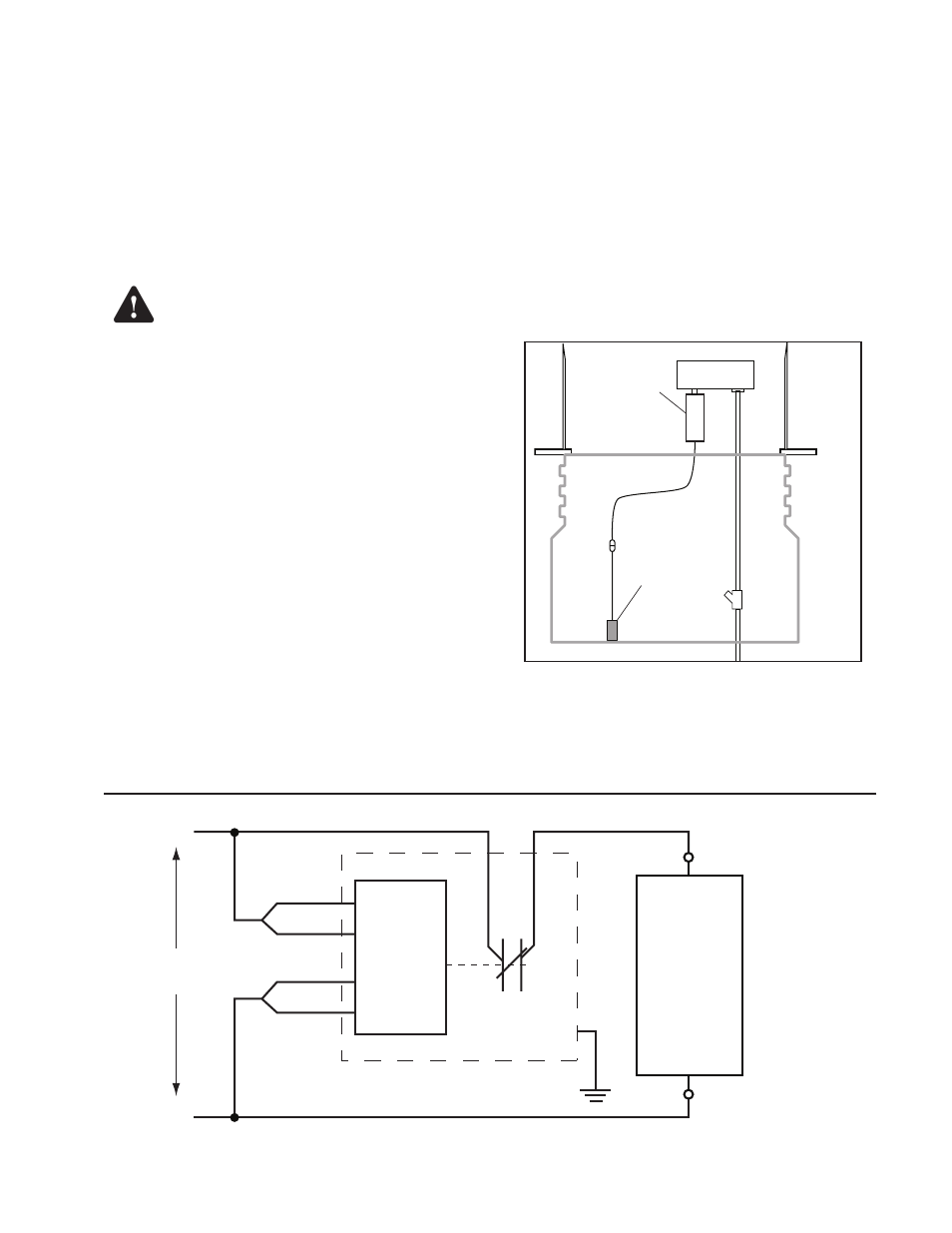

6. Connect the wires as shown in Figure 1.

7. Plug the sensor into the 4 - wire female plug on

the end of the controller. Wrap the plugs with the

electrical tape.

Never plug or unplug the sensor unless

the controller is de-energized. Doing so

will damage the unit.

8. Place the sensor into the bottom of the sump at

the level to cause dispenser shutdown (Figure 2).

Remember that the unit will shut down when the

sensor detects liquid.

9. Loop and secure the excess cable with a tie-wrap

so that the sensor is suspended at the appropriate

position. The S404 float sensor must be installed

in a vertical orientation for proper operation!

10. Replace the junction box cover.

11. Turn the dispenser power back on. The dispenser

should operate normally.

12. If the float sensor causes the dispenser to shut

down, the sensor must be reset by pushing the

float back down with the provided reset tool

through the vent hole in the sensor top to restore

power to the dispenser. The optical sensor does

not need to be reset.

Note: Use only the provided reset tool to push the float down.

404-4

Controller

S406 or

S404 sensor

Dispenser

Junction Box

EYS

Dispenser

Sump

Figure 2: System Installed in Dispenser Sump

CAUTION:

Relay

Dispenser

Red

Black

Orange / Black

Dispenser

110 VAC Input

Dispenser

Neutral

Orange

Blue

Yellow

N.C.

110 VAC

L1

Neutral

Green

404-4 Controller

Figure 1: 110 VAC Wiring Schematic for Controller Dispenser Connection

Warning