Testing the ts-rom2, Relay & led truth table, Active off mode, no-contact configuration – Franklin Fueling Systems TS-ROM2 User Manual

Page 7: Active off mode, nc-contact configuration, Active on mode, no-contact configuration

7 of 8

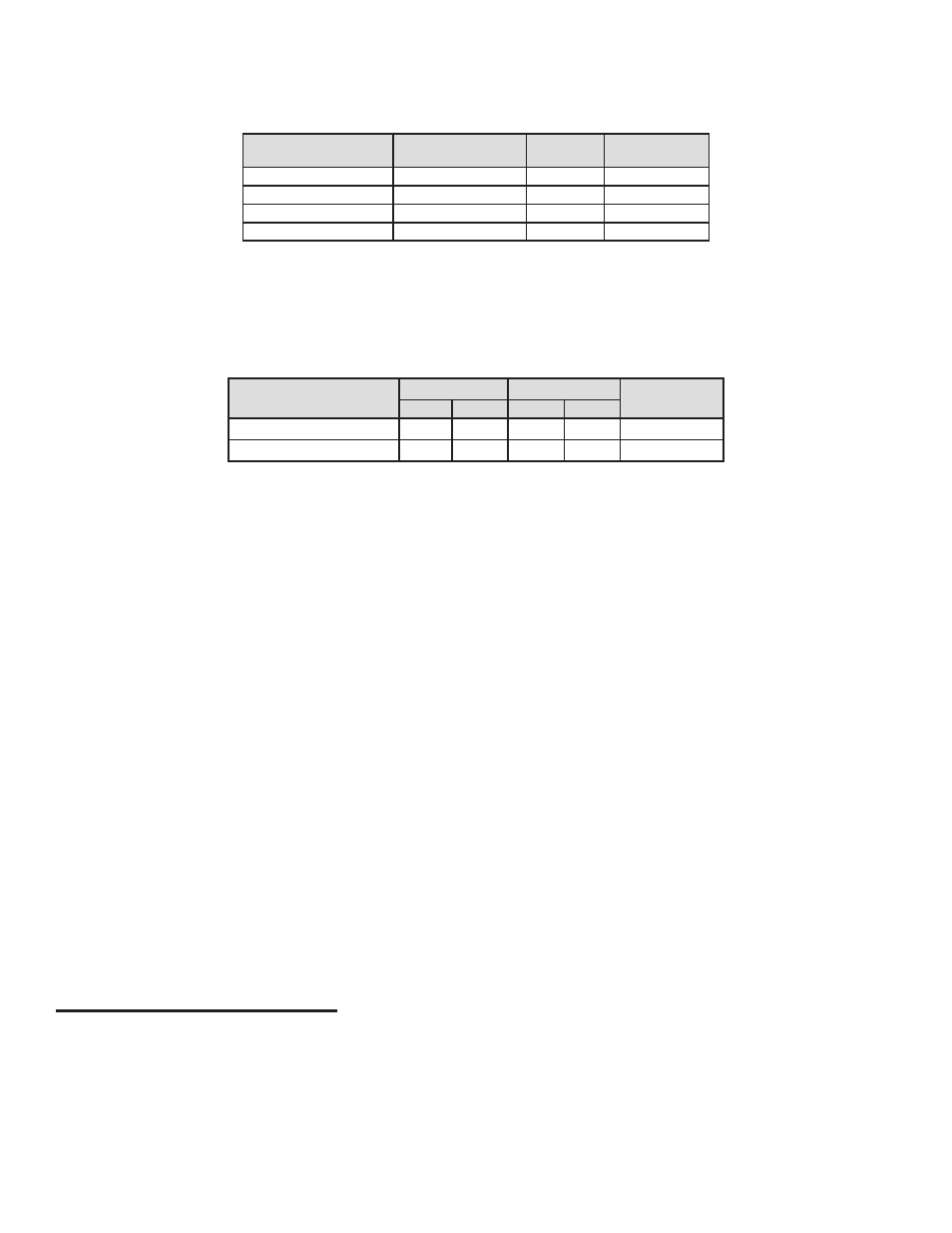

Table 1 – Example: Tank Sentinel or ATG Relay Output Assignments

TS-ROM2: Channel Output No. & Relay Contact Selection,

Dispenser Pump Relay No., Tank No. and Output Control

(Alarm Assignments)

Output Channel # &

(Relay Contact)

Circuit or Device

Description

Pump

Relay No.

Tank No.

OUT 1 (NO): @

Dispenser Pump

1

1

OUT 2 (NO): @

Dispenser Pump

2

2

OUT 3 (NC): @

Tank Leak Light

—

1 & 2

OUT 4 (NO): !

Sump High Light

—

2

Note: @ = SW1-n Active OFF, and ! = SW1-n Active ON

Refer to Table 1 above: Three outputs are configured in Active OFF mode (SW 1: -1, -2, & -3 = OFF

@) and one output

is configured in the Active ON Mode (SW 1: -4 = ON !). In addition, one output channel fuse is installed in the normally

closed contact position

(F3NC) and all other fuses are in the normally open (FnNO) contact position.

Relay & LED Truth Table

Relay Contact and Fuse

(Channel N) Position:

w/o alarms

with alarms

X = ON/Closed

O = OFF/Open

FnNO

FnNC

FnNO

FnNC

@ Active OFF Configuration

X

O

O

X

(SW1-n OFF)

! Active ON Configuration

O

X

X

O

(SW1-n ON)

Note: The Table 1 example, and this discussion, do not cover all possible uses of, or assignments to, the TS-ROM2.

Active Off Mode, NO-Contact Configuration

While no alarms exist, the output channels’ relay and relay status LED indicators will be on, and the

NO (normally

open) relay contacts will be held closed. The example above shows Tank 1 and Tank 2 relay outputs setup for product

dispenser pump - disable circuits. The LOW LOW product level limit alarms, and high WATER LIMIT level alarms have

been assigned to CONTROL the output channels. If a LOW LOW or a WATER LIM alarm fault occurs, then the assigned

outputs will turn off, and the previously held closed

NO relay contact will open disabling product dispensing.

Active Off Mode, NC-Contact Configuration

While no alarms exist, the output channels’ relay and relay status LED indicators will be on, and the

NC (normally closed)

relay contacts will be held open. The example above shows Point 1, Point 2, and Point 3 relay outputs have been setup

for a “Tank Leak Indicator” circuit. Point 1, Point 2, and Point 3 alarms have been assigned to CONTROL output channel

number 3. If any of these point fault-alarm occurs, then the assigned output No. 3 will turn off, and the previously held

open

NC relay contact will close and supply power to the “Tank Leak Indicator”.

Active On Mode, NO-Contact Configuration

While no alarms exist, the output channels’ relay and relay status LED indicators will be off, and the

NO (normally open)

relay contacts will be open. The example above shows Point 4 relay output setup for a tank 2 “Sump High Level Indicator”

circuit. Point 4 alarm has been assigned to CONTROL output channel number 4. If a Sump 2 High Point fault-alarm

occurs, then the assigned output No. 4 will turn on, and the previously open

NO relay contact will close and supply power

to the “Sump High - Level Indicator”.

Testing the TS-ROM2

After the TS-ROM2 is installed and programed, test all of the point sensors and tank Liquid Level probes to make sure

that they are operating properly with the TS-ROM2. Verify all functions according to your programming and jumper

settings. All new Tank Sentinel systems and new point sensors must be tested.

Note: If your ATG (except for the TS-750) does not automatically recognize your TS-ROM2, please contact Technical

Support.