Installation procedures, Electrical connections continued – Xylem IM131R01 AQUAVAR AV II User Manual

Page 25

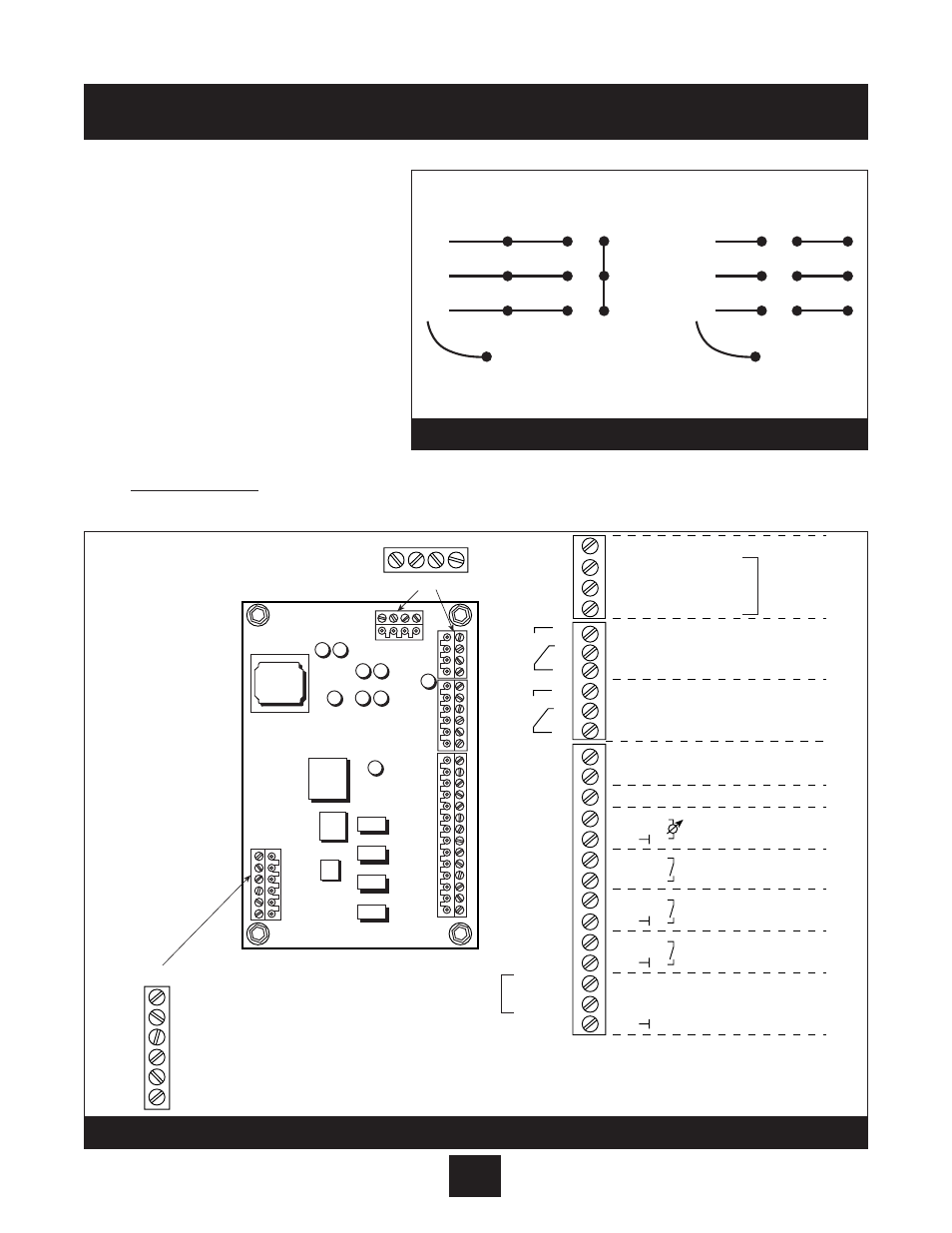

Electrical Connections continued

1. The wires routed from the

terminal block U, V, W, and

ground screw, should now be

connected to the motor leads

using the motor nameplate and

Diagram 6 for reference. Always

refer to motor wiring nameplate.

2. Pressure Transducer

Installation and Wiring

It is recommended that the

transducer be mounted in the

discharge piping. The location should be in a non-turbulent, straight piece of pipe. See layout

on page 5. Locate the adapter for the pressure transducer, if needed.

Installation Procedures

24

220 Volt

460 Volt

AQU

A

VA

R

WU

V

GROUND = PE

AQU

A

VA

R

789

GROUND = PE

456

789

12

3

12

3

WU

V

6

54

Diagram 6

BROWN – 3

WHITE – 2

4

3

2

1

6

5

4

3

2

1

14

13

12

11

10

9

8

7

6

5

4

3

2

1

+ 5VDC

GND

SIO +

SIO -

15 V

IN

(4-20 mA)

RS-485

connected to drive

“Run Signal”

fault signal

Current Signal Input (4-20 mA)

Analog signal output (0-10V)

connected to drive

Motor thermo or PTC *

low Water or jumper *

external on or jumper *

U

b

(max 100 mA)

actual value signal

shielding

X1

X2

Multi-

pump

Transducer

connection

X5

NO

CC

NC

NO

CC

NC

Digital Input

Voltage Signal Input (0-10Vor 2-10V)

X2

6

5

4

3

2

1

12

11

10

9

8

7

6

5

4

3

2

1

X1

13

14

X5

4

3

2

1

X6

4 3 2 1

RS485

6 – CONNECTED TO DRIVE

5 – CONNECTED TO DRIVE JUMPER

4 – CONNECTED TO DRIVE JUMPER

3 – CONNECTED TO DRIVE

2 – ANALOG OUT (PRESSURE)

1 – RETURN SIGNAL

X9

* NOTE: Jumpers are installed from the factory.

Must remove to wire motor thermal, low water

switch or external ON/OFF if used.

- 24 VDC

+ 24 VDC

+ 24 VDC

FAULT RELAY

Diagram 7