Installation procedures, Step 6 - maintenance, Step 7 - general wiring information – Xylem IM131R01 AQUAVAR AV II User Manual

Page 18

Installation Procedures

17

Electrical Connections continued

Step 6 - Maintenance

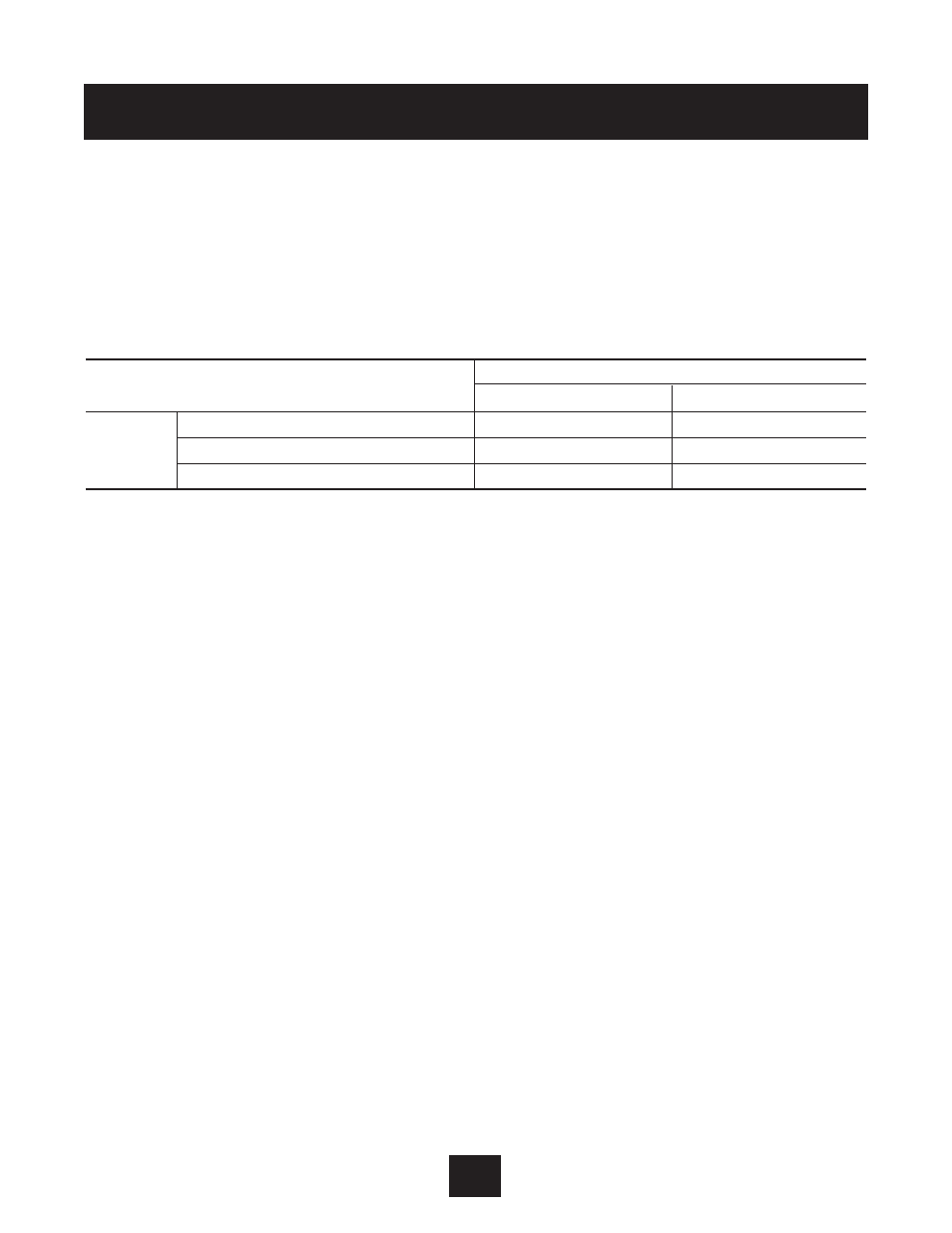

Minimum Torque Values to Secure Cover

If you remove the cover of an IP55 AQUAVAR controller, it is imperative that the cover be

closed and re-secured with sufficient tightness to maintain environmental integrity. The table

below specifies the torque values for the bolts that secure the covers on the various models.

Step 7 - General Wiring Information

Wiring Practices

When making power and control connections, observe these precautions:

• Follow all Federal, State, NEC codes and local codes.

• Never connect input AC power to the motor output terminals T1/U, T2/V or T3/W – or

damage to the controller will result.

• Power wiring to the motor must have the maximum possible separation from all other power

wiring. Do not run in the same conduit, this separation reduces the possibility of coupling

electrical noise between circuits.

• Cross conduits at right angles whenever power and control wiring cross.

• Good wiring practice also requires separation of control circuit wiring from all power wiring.

Since power delivered from the controller contains high frequencies which may cause

interference with other equipment, do not run control wires in the same conduit or raceway

with power or motor wiring.

Considerations for Power Wiring

Power wiring refers to the line and load connections made to terminals L1/R, L2/S, L3/T and

T1/U, T2/V, T3/W respectively. Select power wiring as follows:

• Use only UL recognized wire. (Shielded or armored wire is recommended for power and motor

wiring.)

• Wire voltage rating must be a minimum of 300 V for 230 Vac systems and 600 V (Class 1 wire)

for 460 Vac and 575 Vac systems.

AV2 Enclosure Type

Torque Value

English

Metric

1-20 HP, 230 Vac input

12 in-lbs

1.35 Nm

IP55

1-20 HP, 460 and 575 Vac input

18 in-lbs

2.03 Nm

25-75 HP, 460 and 575 Vac input

12 in-lbs

1.35 Nm