Test configurations, Design considerations, Safety considerations – GE Industrial Solutions QPW025A0F41_H User Manual

Page 6

Data Sheet

October 5, 2009

QPW025A0F41/QPW025A0F41-H DC-DC Power Module

36-75Vdc Input; 3.3Vdc Output Voltage; 25A Output Current

LINEAGE

POWER

6

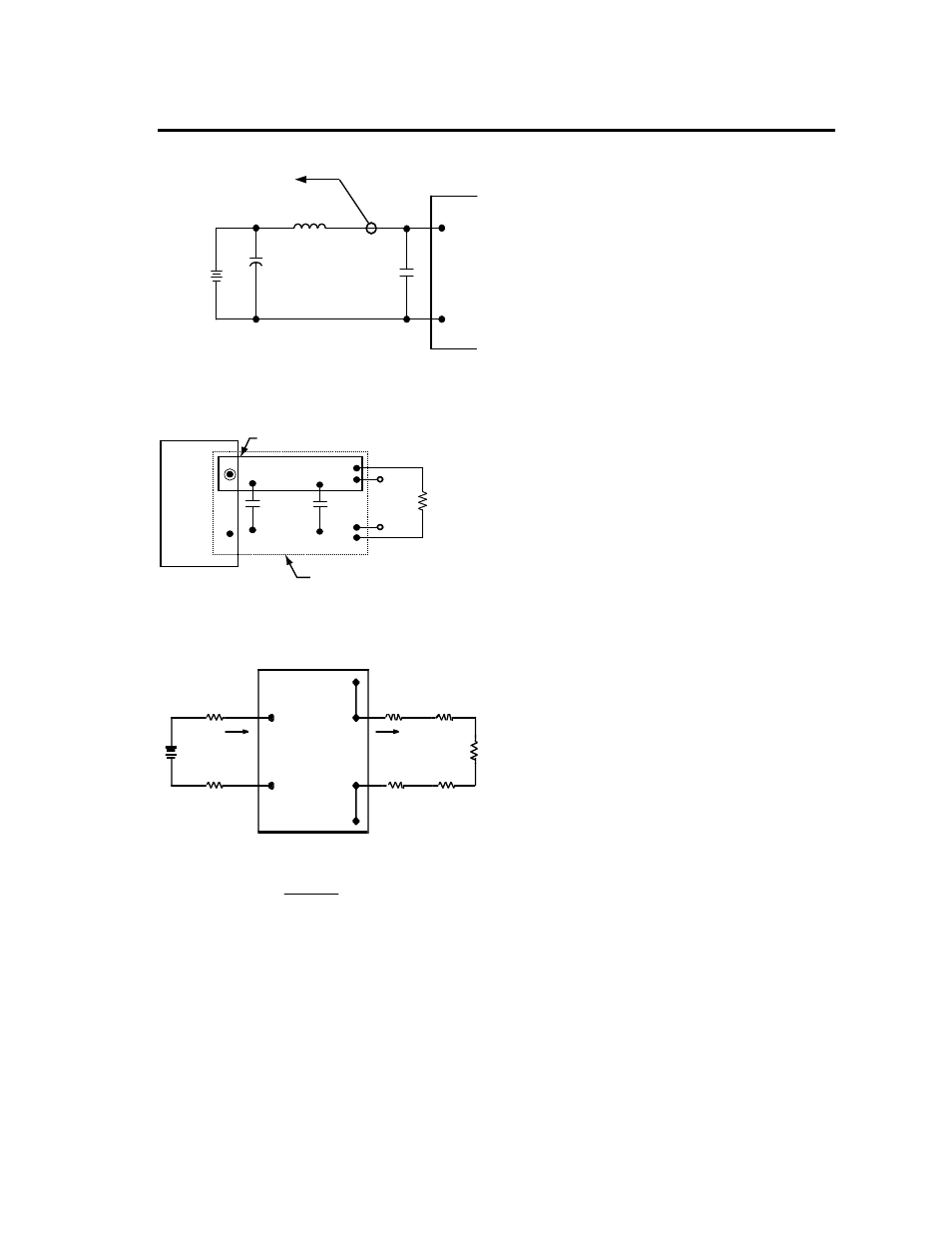

Test Configurations

TO OSCILLOSCOPE

12 µH

C

S

220 µF

ESR < 0.1 W

@ 20 °C, 100 kHz

V

I

(+)

V

I

(-)

BATTERY

33 µF

CURRENT

PROBE

L

TEST

ESR < 0.7 W

@ 100 kHz

Note: Input reflected-ripple current is measured with the simulated

source inductance of 1uH. Capacitor Cs offsets possible battery

impedance. Current is measured at the input of the module

Figure 7. Input Reflected Ripple Current Test Setup.

V

O

(+)

V

O

(–)

1.0 µF

RESISTIV

LOAD

SCOPE

COPPER STRIP

GROUND PLANE

10 µF

Note: Use a 10uF tantalum and a 1uF ceramic capacitor. Scope

measurement should be made using BNC socket. Position the load

between 51 mm and 76mm (2 in. and 3 in.) from the module

Figure 8. Output Ripple and Noise Test Setup.

V

I

(+)

I

I

I

O

SUPPLY

CONTACT

CONTACT AND

LOAD

SENSE(+)

V

I

(–)

V

O

(+ )

V

O

(–)

SENSE(–)

RESISTANCE

DISTRIBUTION LOSSES

Figure 9. Output Voltage and Efficiency Test Setup.

η =

V

O

. I

O

V

IN

. I

IN

x

100 %

Efficiency

Design Considerations

Input Source Impedance

The power module should be connected to a low

ac-impedance input source. Highly inductive source

impedances can affect the stability of the power module.

For the test configuration in Figure 7, a 33 µF

electrolytic capacitor (ESR < 0.7

Ω at 100 kHz) mounted

close to the power module helps ensure stability of the

unit. Consult the factory for further application

guidelines

.

Output Capacitance

High output current transient rate of change (high di/dt)

loads may require high values of output capacitance to

supply the instantaneous energy requirement to the

load. To minimize the output voltage transient drop

during this transient, low E.S.R. (equivalent series

resistance) capacitors may be required, since a high

E.S.R. will produce a correspondingly higher voltage

drop during the current transient.

Output capacitance and load impedance interact with

the power module’s output voltage regulation control

system and may produce an ’unstable’ output condition

for the required values of capacitance and E.S.R.

Minimum and maximum values of output capacitance

and of the capacitor’s associated E.S.R. may be

dictated, depending on the module’s control system.

The process of determining the acceptable values of

capacitance and E.S.R. is complex and is load-

dependant. Lineage Power provides Web-based tools to

assist the power module end-user in appraising and

adjusting the effect of various load conditions and output

capacitances on specific power modules for various

load conditions

Safety Considerations

For safety-agency approval of the system in which the

power module is used, the power module must be

installed in compliance with the spacing and separation

requirements of the end-use safety agency standard,

i.e., UL60950-1, CSA C22.2 No. 60950-1-03, EN60950-

1 and VDE 0805:2001-12.

For end products connected to –48V dc, or –60Vdc

nominal DC MAINS (i.e. central office dc battery plant),

no further fault testing is required. For all input voltages,

other than DC MAINS, where the input voltage is less

than 60V dc, if the input meets all of the requirements

for SELV, then:

The output may be considered SELV. Output

voltages will remain within SELV limits even with

internally-generated non-SELV voltages. Single