GE Industrial Solutions QPW025A0F41_H User Manual

Page 10

Data Sheet

October 5, 2009

QPW025A0F41/QPW025A0F41-H DC-DC Power Module

36-75Vdc Input; 3.3Vdc Output Voltage; 25A Output Current

LINEAGE

POWER

10

Please refer to the Application Note “Thermal

Characterization Process For Open-Frame Board-

Mounted Power Modules” for a detailed discussion of

thermal aspects including maximum device

temperatures.

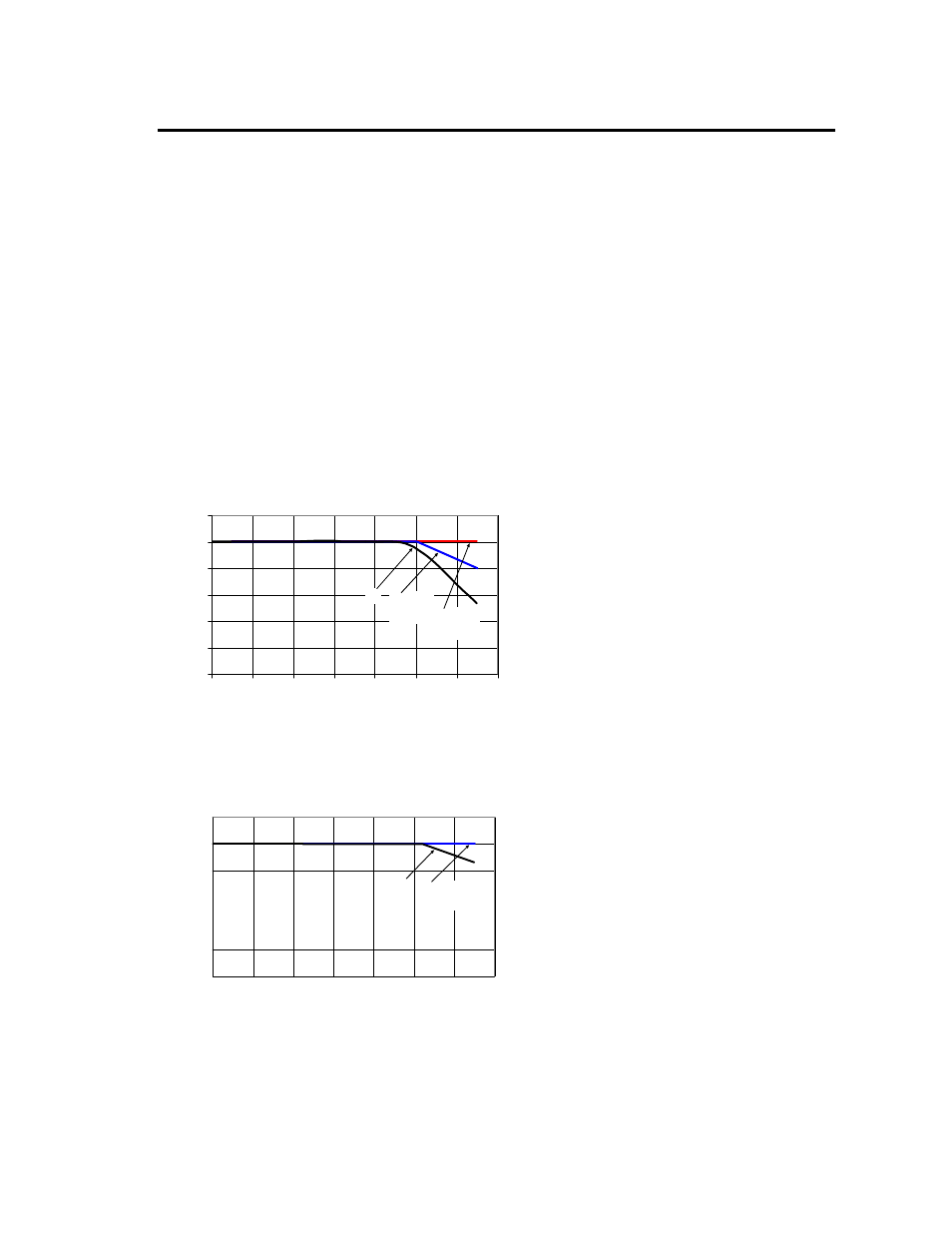

Heat Transfer via Convection

Increased airflow over the module enhances the heat

transfer via convection. Thermal derating curves

showing the maximum output current that can be

delivered by the module versus local ambient

temperature (T

A

) for natural convection, 0.5m/s (100

ft./min) and 1.0 m/s (200 ft./min) are shown in Fig. 15 for

the bare module and in Fig. 16 for the module with

baseplate.

Note that the natural convection condition was

measured at 0.05m/s to 0.1m/s (10ft./min. to 20ft./min.);

however, systems in which these power modules may

be used typically generate natural convection airflow

rates of 0.3m/s (60 ft./min.) due to other heat dissipating

components in the system.

0

5

10

15

20

25

30

20

30

40

50

60

70

80

90

0.5 m/s

(100 lfm) 1.0 m/s

(200 lfm)

NC

OUTP

U

T

CU

RR

E

N

T (

A

)

TEMPERATURE (

O

C)

Figure 15. Thermal Derating Curves for the

QPW025A0F41 module at 48Vin. Airflow is in the

transverse direction (Vin

− to Vin+).

0

5

10

15

20

25

30

20

30

40

50

60

70

80

90

0.5 m/s

(100 lfm)

NC

O

U

TP

UT

C

URRE

NT

(A

)

TEMPERATURE (

O

C)

Figure 16. Thermal Derating Curves for the

QPW025A0F41-H baseplate module at 48Vin. Airflow

is in the transverse direction (Vin

− to Vin+).