GE Industrial Solutions HE300GEN150 User Manual

Page 29

PAGE 30 13 APR 2000 MAN0373-01

CH. 5

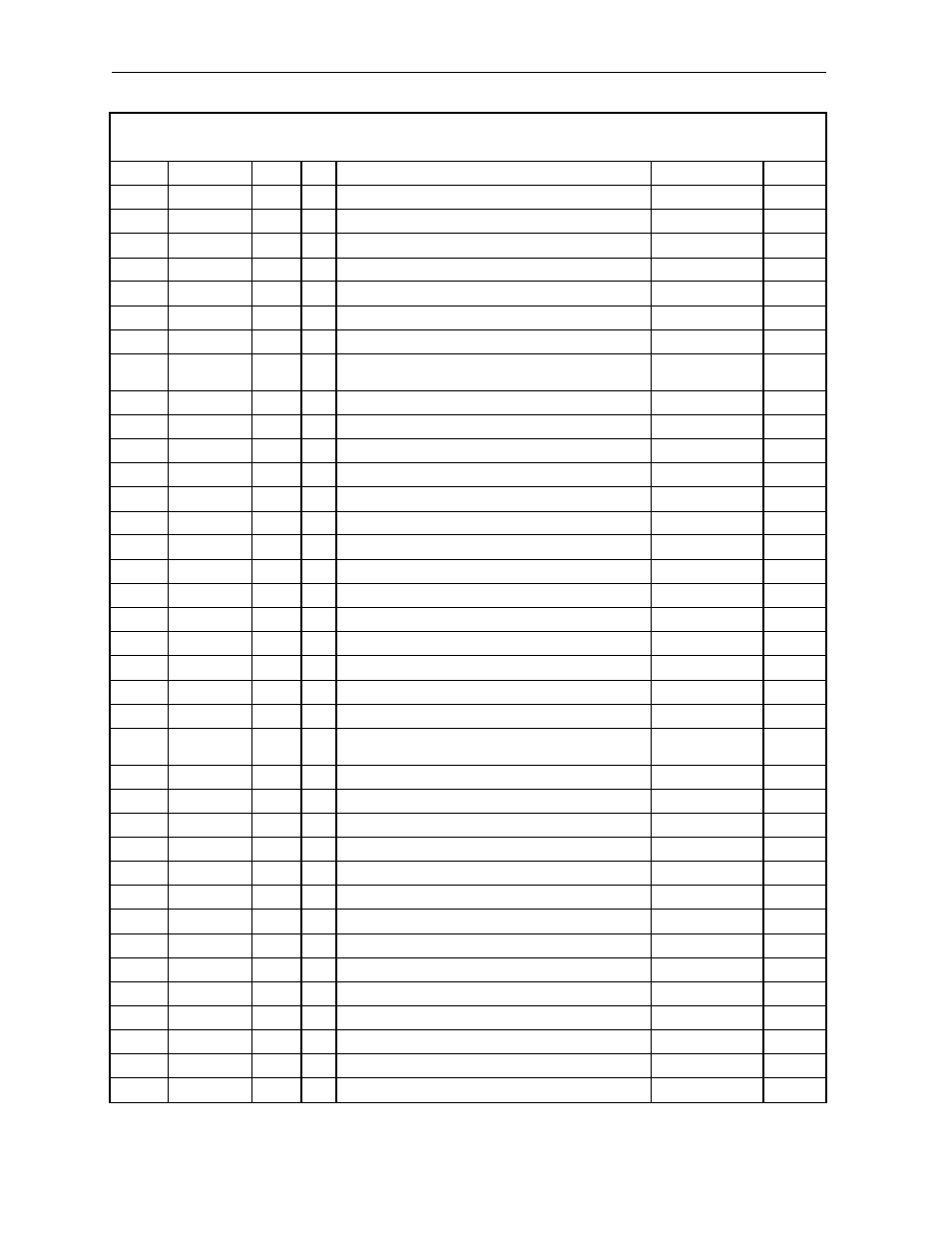

Table 5.1 – Communication Parameter Index

185

H23

B9

PID control (I-gain)

I-GAIN

3

186

H24

BA

PID control (D-gain)

D-GAIN

1

187

H25

BB

PID control (Feedback filter)

FB FILTER

5

188

H26

BC

PTC thermistor (Mode select)

PTC MODE

1

189

H27

BD

PTC thermistor (Level)

PTC LEVEL

5

190

H28

BE

Droop operation

DROOP

4

191

H30

BF

Serial link (Function select)

LINK FUNC

1

192

H31

C0

Modbus-RTU (Address)

ADDRESS

1

193

H32

C1

Modbus-RTU (Mode select on no response

error)

MODE ON ER

1

194

H33

C2

Modbus-RTU (Timer)

TIMER

3

195

H34

C3

Modbus-RTU (Baud rate)

BAUD RATE

1

196

H35

C4

Modbus-RTU (Data length)

LENGTH

1

197

H36

C5

Modbus-RTU (Parity check)

PARITY

1

198

H37

C6

Modbus-RTU (Stop bits)

STOP BITS

1

199

H38

C7

Modbus-RTU (No resp. error detection time) NO RES t

1

200

H39

C8

Modbus-RTU (Response interval)

INTERVAL

5

201

A01

C9

Maximum frequency 2

MAX Hz-2

1

202

A02

CA

Base frequency 2

BASE Hz-2

1

203

A03

CB

Rated voltage 2 (at Base frequency 2)

RATED V-2

1

204

A04

CC

Maximum voltage 2

MAX V-2

1

205

A05

CD

Torque boost 2

TRQ BOOST2

1

206

A06

CE

Electronic thermal 2 (Select)

ELCTRN OL2

1

207

A07

CF

Electronic thermal 2 (Level)

OL LEVEL2

19

208

A08

D0

Electronic thermal 2 (Thermal time

constant)

TIME CNST2

3

209

A09

D1

Torque vector control 2

TRQVECTOR2

1

210

A10

D2

Number of motor 2 poles

M2 POLES

1

211

A11

D3

Motor 2 (Capacity)

M2-CAP

5

212

A12

D4

Motor 2 (Rated current)

M2-Ir

19

213

A13

D5

Motor 2 (Tuning)

M2 TUN1

21

214

A14

D6

Motor 2 (On-line Tuning)

M2 TUN2

1

215

A15

D7

Motor 2 (No-load current)

M2-Io

19

216

A16

D8

Motor 2 (%R1 setting)

M2-%R1

5

217

A17

D9

Motor 2 (%X setting)

M2-%X

5

218

A18

DA

Motor 2 (Slip compensation control 2)

SLIP COMP2

5

219

o01

DB

Control method selection

1

220

o02

DC

Speed filter time constant

1

221

o03

DD

Number of feedback pulses

1

222

o04

DE

P-gain of feedback

1