Overload heaters for fused controllers – GE Industrial Solutions Evolution Series E9000 User Manual

Page 31

30

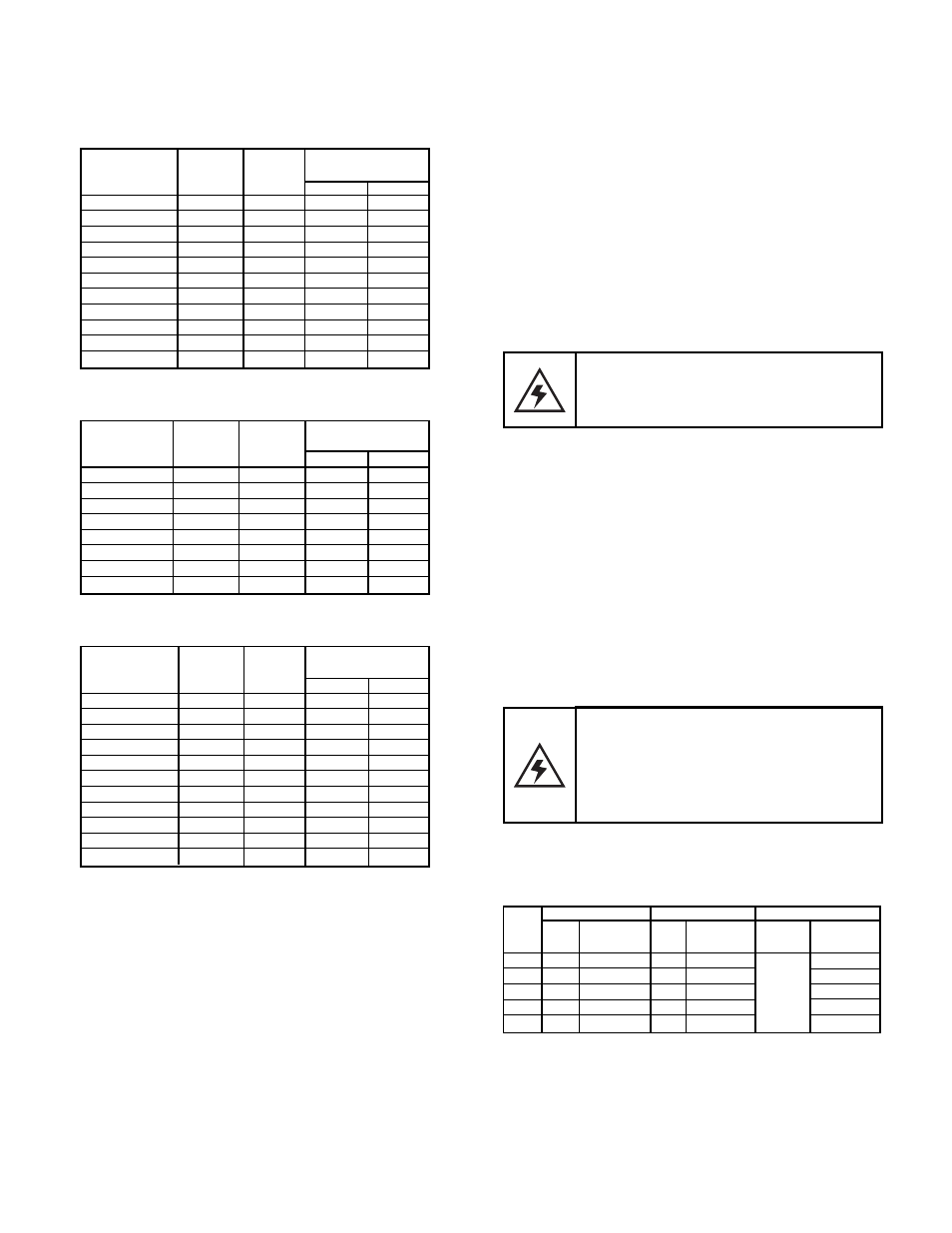

Size 5 – 300:15 CT (Standard and Ambient Comp.)

Size 6 – 600:5 CT (Standard and Ambient Comp.)

Size 6 – 600:5 CT (Standard and Ambient Comp.)

Overload Heaters for Fused Controllers

For continuous-rated motors with a service factor of

1.15 to 1.25, select the appropriate heaters for the

motor full-load current. For continuous-rated motors

with a service factor of 1.0, multiply the motor full-load

current by 0.9 and use this value to select heaters.

Overload relay tripping current in 40° C ambient is the

minimum value of full-load current multiplied by 1.25.

Provide short-circuit protection in accordance with the

National Electrical Code, except that fuses are not to

exceed the value shown in the table.

Suitable for use in a circuit capable of delivering not

more than the maximum RMS symmetrical amperes

indicated in the Maximum Fuse and Short-Circuit

Rating table below, 600 V maximum, when protected

by an appropriate fuse having an interrupting rating

not less than the available short-circuit current.

Maximum Fuse and Short-Circuit Rating

Class RK Fuse

Class J Fuse

Class K-1, K-5 Fuse

NEMA

Max.

Max. RMS

Max.

Max. RMS

Max.

Max. RMS

Size

Clip

Sym. Amps

Clip

Sym. Amps

Clip

Sym. Amps

1

30A

100,000

60A

100,000

Fuse

5,000

2

60

100,000

100

100,000

per

5,000

3

100

100,000

200

100,000

Overload

5,000

4

200

100,000

400

100,000

Heater

10,000

5

400

100,000

600

100,000

Table

10,000

Opening of the fuse(s) may be an indication that

a fault current has been interrupted. To provide

continued protection against fire or shock hazard,

examine all current-carrying parts and other

components of the motor controller and replace any

damaged components. If heater burnout occurs,

the complete overload relay must be replaced.

Overload relays with automatic reset may auto-

matically start a motor connected to a two-wire

control circuit. When automatic restarting is not

desired, use a three-wire control circuit.

Motor Full-

Heater

SK

Instantaneous

Load Amps

Number

Rating

Trip Setting

3-Ph, 3 Heater

CR123

Plug

Rec.

Max.

181-197

C220A

400

LO

4

198-214

C239A

400

2

4

215-238

C268A

400

3

5

239-258

C301A

500

LO

4

259-290

C326A

500

2

5

291-346

C356A

800

LO

4

347-387

C379A

800

LO

5

388-423

C419A

800

2

5

424-467

C466A

1000

LO

4

468-516

C526A

1000

2

4

517-540

C592A

1000

2

5

Motor Full-

Heater

SG

Instantaneous

Load Amps

Number

Rating

Trip Setting

3-Ph, 3 Heater

CR123

Plug

Rec.

Max.

181-197

C220A

400

MIN.

4

198-214

C239A

400

2

5

215-238

C268A

500

MIN

4

239-258

C301A

500

MIN

4

259-290

C326A

500

2

5

291-346

C356A

600

MIN

5

347-387

C379A

600

2

5

388-424

C419A

600

3

MAX

Motor Full-

Heater

SG

Instantaneous

Load Amps

Number

Rating

Trip Setting

3-Ph, 3 Heater

CR123

Plug

Rec.

Max.

106-115

C592A

250

LO

3

116-125

C630A

250

LO

4

126-135

C695A

250

2

4

136-151

C778A

250

2

5

152-164

C867A

300

2

4

165-179

C955A

300

2

5

180-195

C104B

350

2

4

196-215

C113B

350

2

5

216-231

C125B

400

2

4

232-255

C137B

400

2

5

256-270

C151B

400

3

5

Evolution Series E9000 Installation & Maintenance Guide