Heaters for mag-break, Controllers – GE Industrial Solutions Evolution Series E9000 User Manual

Page 26

25

Evolution Series E9000 Installation & Maintenance Guide

Size 5 (Standard and Ambient Comp.)

Heaters for Mag-Break

®

Controllers

The Mag-Break protector is factory adjusted to the

minimum trip setting.

For continuous-rated motors with a service factor of

1.15 to 1.25, select the appropriate heaters for the

motor full-load current. For continuous-rated motors

with a service factor of 1.0, multiply the motor full-load

current by 0.9 and use this value to select heaters.

Use the heater table to verify that the Mag-Break and

current limiter rating is correct for the motor full-load

current. Then set the Mag-Break trip setting to the

recommended value.

If the Mag-Break trips during motor startup, increase

the trip setting by one step at a time until the motor

can be consistently started. Do not exceed the maximum

trip setting shown in the heater table.

Overload relay tripping current in 40° C ambient is the

minimum value of heater full-load current multiplied

by 1.25.

Size 0 and 1 (Standard )

Circuit breaker tripping may be an indication that

a fault current has been interrupted. To provide

continued protection against fire or shock hazard,

examine all current-carrying parts and other

components of the motor controller and replace

any damaged components. If heater burnout

occurs, the complete overload relay must be replaced.

To maintain overload, short-circuit, and ground-

fault protection, use the following instructions

to select heaters and to adjust the Mag-Break

trip setting.

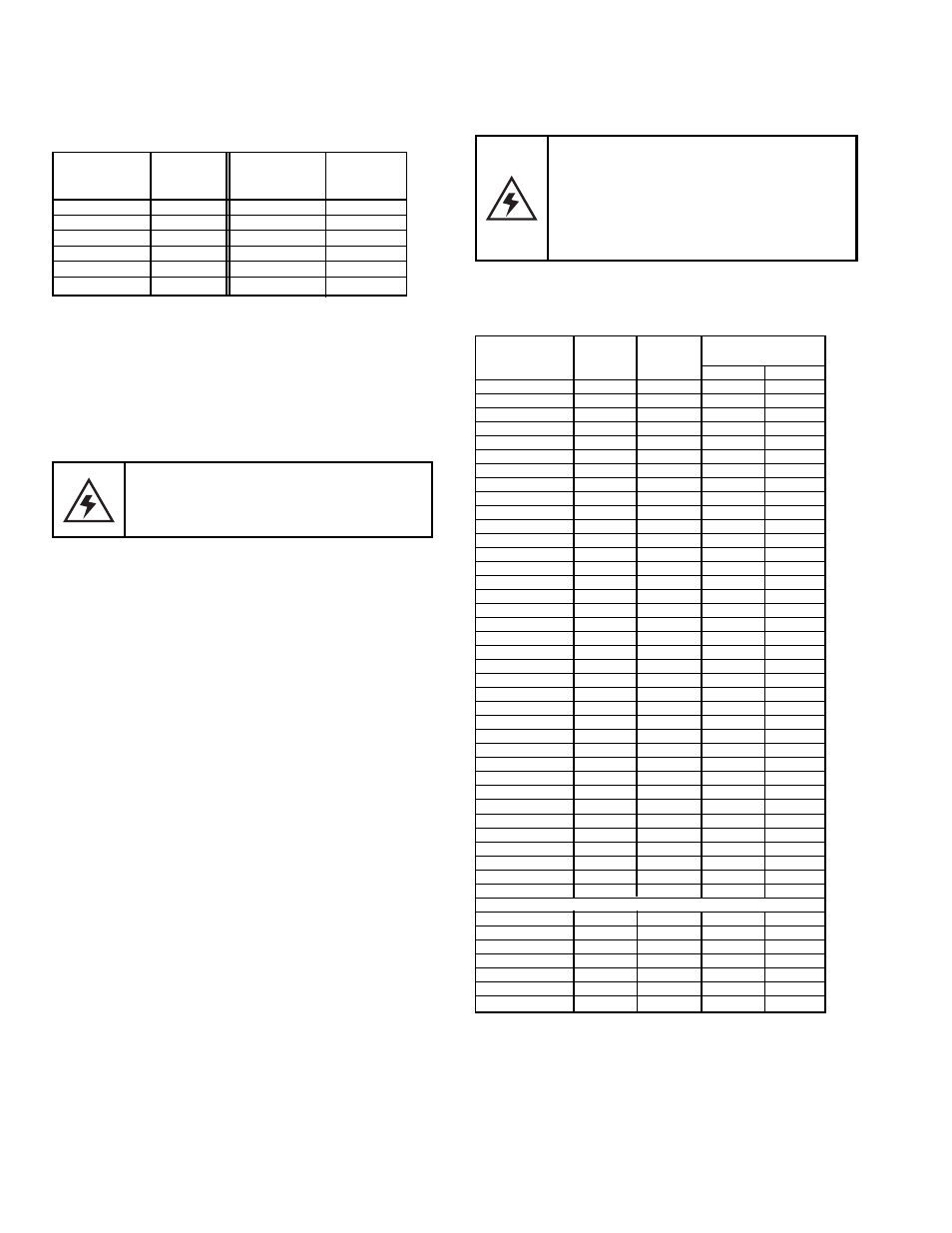

Motor Full-

Heater

TEC &

Mag-Break

Load Amps

Number

TECL

Trip Setting

3-Ph, 3 Heater

CR 123

Rating

Rec.

Max.

.65-.74

C087A

3

LO

LO

.75-.84

C097A

3

LO

LO

.85-.92

C109A

3

LO

1

.93-1.02

C118A

3

LO

1

1.03-1.10

C131A

3

LO

2

1.11-1.23

C148A

3

LO

2

1.24-1.38

C163A

3

LO

3

1.39-1.49

C184A

3

LO

4

1.50-1.67

C196A

3

1

4

1.68-1.79

C220A

3

1

5

1.80-1.98

C239A

3

1

6

1.99-2.24

C268A

3

2

7

2.25-2.43

C301A

3

3

8

2.25-2.43

C301A

7

LO

1

2.44-2.75

C326A

7

LO

2

2.76-3.25

C356A

7

LO

3

3.26-3.43

C379A

7

LO

4

3.44-4.03

C419A

7

1

4

4.04-4.43

C466A

7

1

5

4.44-4.94

C526A

7

2

6

4.95-5.36

C592A

7

2

7

5.37-5.77

C630A

7

3

6

5.37-5.77

C630A

15

LO

2

5.78-6.35

C695A

15

LO

2

6.36-6.92

C778A

15

LO

3

6.93-7.99

C867A

15

LO

3

8.00-8.47

C955A

15

1

4

8.48-9.19

C104B

15

1

5

9.20-10.0

C113B

15

1

6

10.1-10.7

C125B

15

2

6

10.8-12.0

C137B

15

2

7

10.8-12.0

C137B

30

LO

2

12.1-12.9

C151B

15

3

8

12.1-12.9

C151B

30

LO

2

13.0-15.1

C163B

30

LO

3

15.2-16.3

C180B

30

LO

4

16.4-17.9

C198B

30

1

4

Size 1

18.0-19.7

C214B

30

1

5

19.8-21.2

C228B

30

1

6

21.3-22.3

C250B

30

2

7

22.4-23.5

C273B

30

2

8

23.6-25.5

C303B

30

3

8

23.6-25.5

C303B

50

LO

3

25.6-27.0

C330B

50

LO

3

Motor Full-

Heater

Motor Full-

Heater

Load Amps

Number

Load Amps

Number

3-Ph, 3 Heater

CR 123

3-Ph, 3 Heater

CR 123

109-118

C592A

185-200

C104B

119-128

C630A

201-221

C113B

129-138

C695A

222-237

C125B

139-155

C778A

238-262

C137B

156-168

C867A

263-270

C151B

169-184

C955A