Through-hole lead-free soldering information – GE Industrial Solutions FLT012A0-SZ User Manual

Page 9

Data Sheet

February 9, 2012

FLT012A0Z/FLT012A0-SZ Input Filter Modules

75Vdc Input Voltage Maximum, 12A Output Current Maximum

LINEAGE

POWER

9

minimum of 12 months from the bag seal date, when

stored at the following conditions: < 40° C, < 90%

relative humidity.

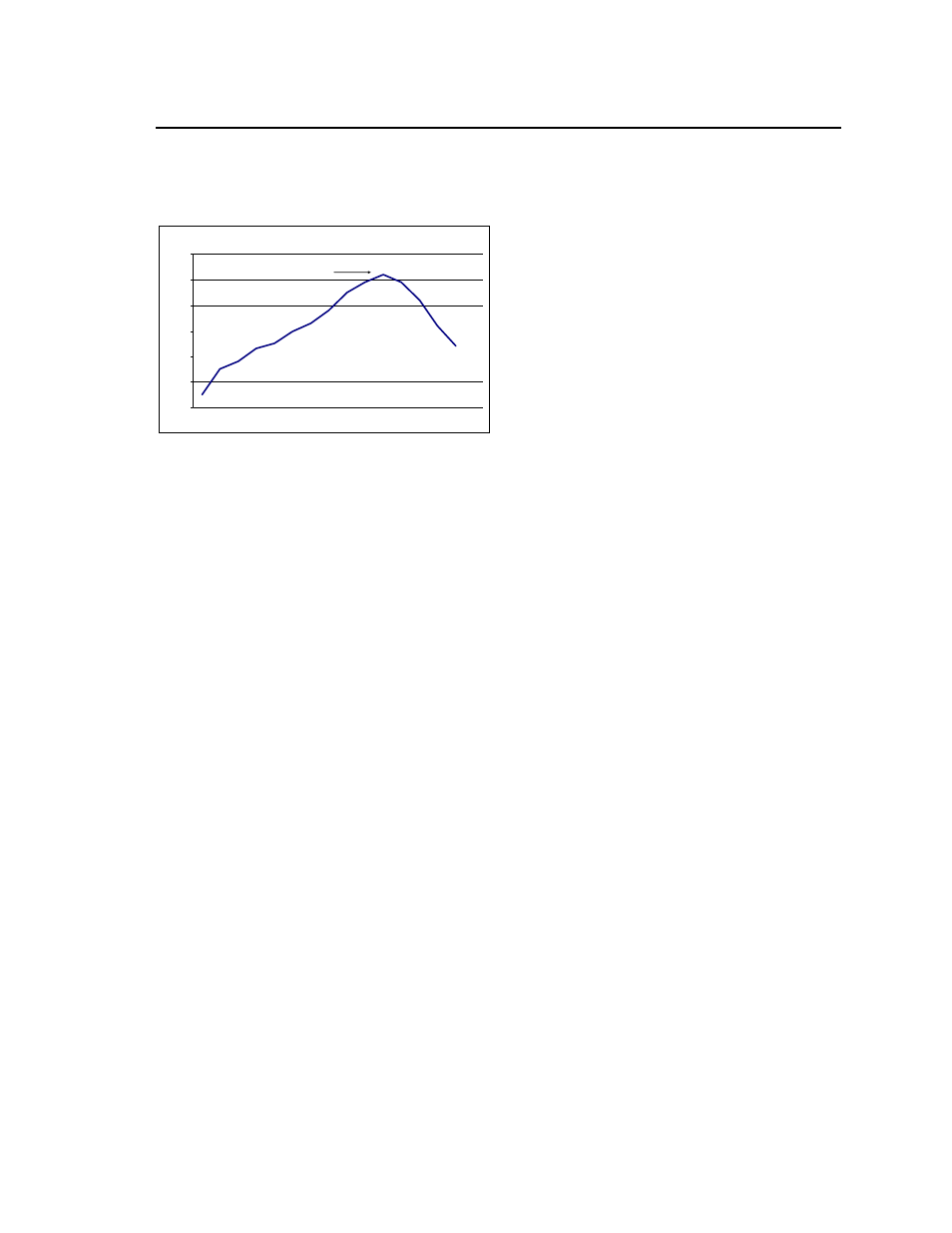

Per J-STD-020 Rev. C

0

50

100

150

200

250

300

Reflow Time (Seconds)

R

efl

ow

Te

m

p (°

C)

Heating Zone

1°C/Second

Peak Temp 260°C

* Min. Time Above 235°C

15 Seconds

*Time Above 217°C

60 Seconds

Cooling Zone

4°C/Second

Figure 15. Recommended linear reflow profile

using Sn/Ag/Cu solder.

Post solder Cleaning and Drying

Considerations

Post solder cleaning is usually the final circuit-board

assembly process prior to electrical board testing. The

result of inadequate cleaning and drying can affect

both the reliability of a power module and the

testability of the finished circuit-board assembly. For

guidance on appropriate soldering, cleaning and

drying procedures, refer to Lineage Power Board

Mounted Power Modules: Soldering and Cleaning

Application Note.(AN04-001)

Through-Hole Lead-Free Soldering

Information

The RoHS-compliant through-hole products use the

SAC (Sn/Ag/Cu) Pb-free solder and RoHS-compliant

components. They are designed to be processed

through single or dual wave soldering machines. The

pins have an RoHS-compliant finish that is compatible

with both Pb and Pb-free wave soldering processes.

A maximum preheat rate of 3

°C/s is suggested. The

wave preheat process should be such that the

temperature of the power module board is kept below

210

°C. For Pb solder, the recommended pot

temperature is 260

°C, while the Pb-free solder pot is

270

°C max. Not all RoHS-compliant through-hole

products can be processed with paste-through-hole

Pb or Pb-free reflow process. If additional information

is needed, please consult with your Lineage Power

representative for more details.