Step 3 – install the handle operating mechanism – GE Industrial Solutions Record Plus Cable Operating Mechanism: FC100, FE250 User Manual

Page 5

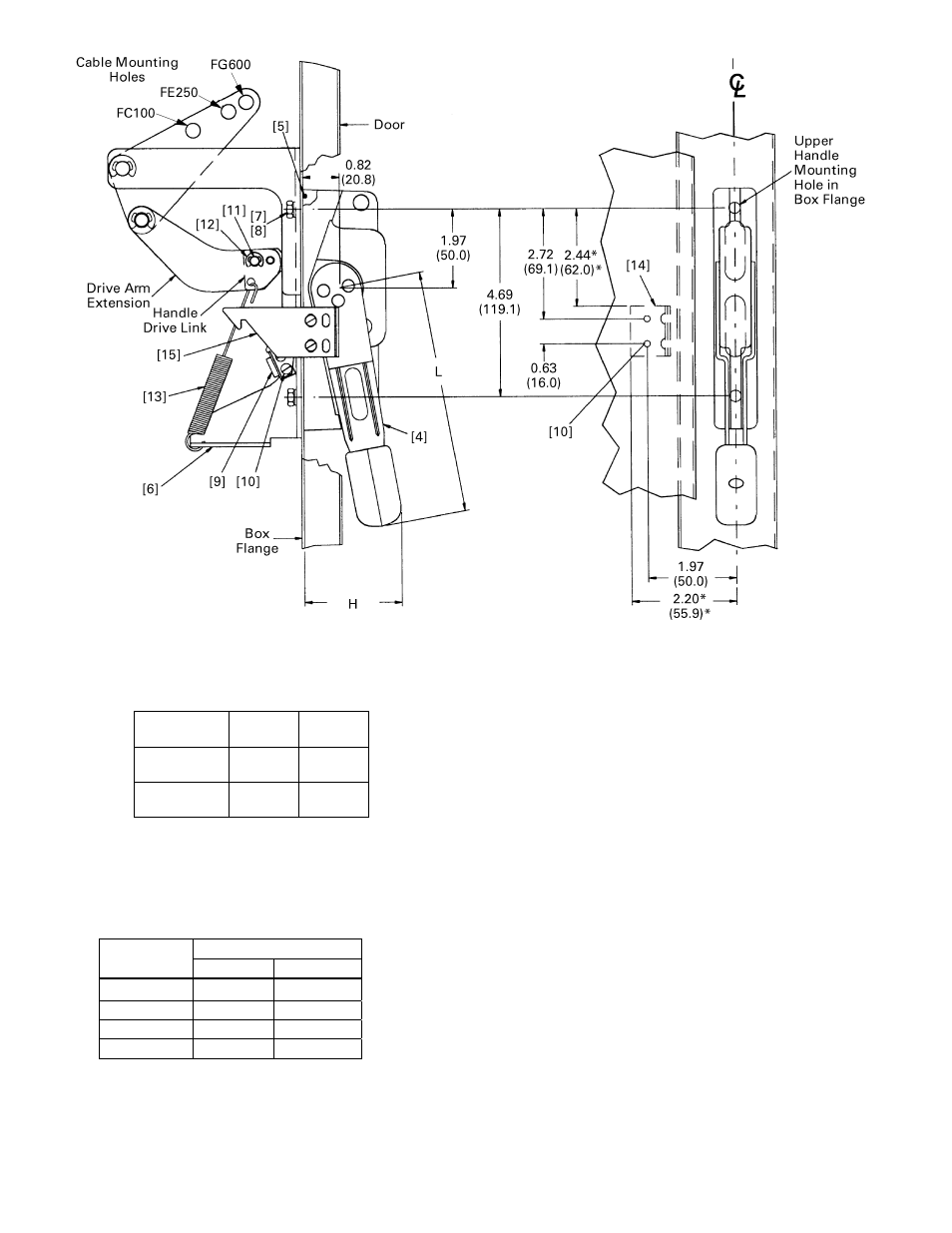

Figure 8. Handle mechanism installation.

Step 3 – Install the Handle

Operating Mechanism

Handle L,

in.

(mm)

H, in.

(mm)

This procedure is illustrated in Figure 2, Figure 5,

Figure 6, Figure 7, and Figure 8. The handle

dimensions, as shown in Figure 8, are listed in

Table7.

FCNHM1 /

FCNHM3

6.04

(153.4)

2.38

(60.5)

FCNHM2 /

FCNHM4

9.38

(238.3)

3.00

(76.2)

1.

In coordination with the location of the breaker,

select the mounting location for the handle

operating mechanism on the flange of the

enclosure. The handle can be mounted on either

the right or the left side of the enclosure.

Table 7. Handle dimensions shown in Figure 8.

2.

If the enclosure flange does not have handle

mounting holes and slots, drill these as shown in

Figure 5 and Figure 6.

3.

Position the O-ring [5] in the groove in the

handle, as shown in Figure . Assemble the handle

[4] and the cable adapter assembly [6] to the

flange of the enclosure with two 1/4-20 x 5/8"

screws [7] and lock washers [8]. Tighten the

screws to torque given as per Table 8.

4.

Attach the interlock blade [9] to the handle with

two #8-32 SEMS screws [10], as shown in Figure

5.

Torque

Screw Size

lb-in N-m

#8-32

16 to 20 1.8 to 2.25

#10-32

27 to 32 3.0 to 3.6

#1/4-20

40 to 50 4.5 to 5.6

Table 8. Tightening torque details

.