Step 1 – unpack and inspect product description – GE Industrial Solutions Record Plus Cable Operating Mechanism: FC100, FE250 User Manual

Page 2

Step 1 – Unpack and Inspect

Product Description

Unpack the cable operator components and

inspect for damage. Verify that all parts are

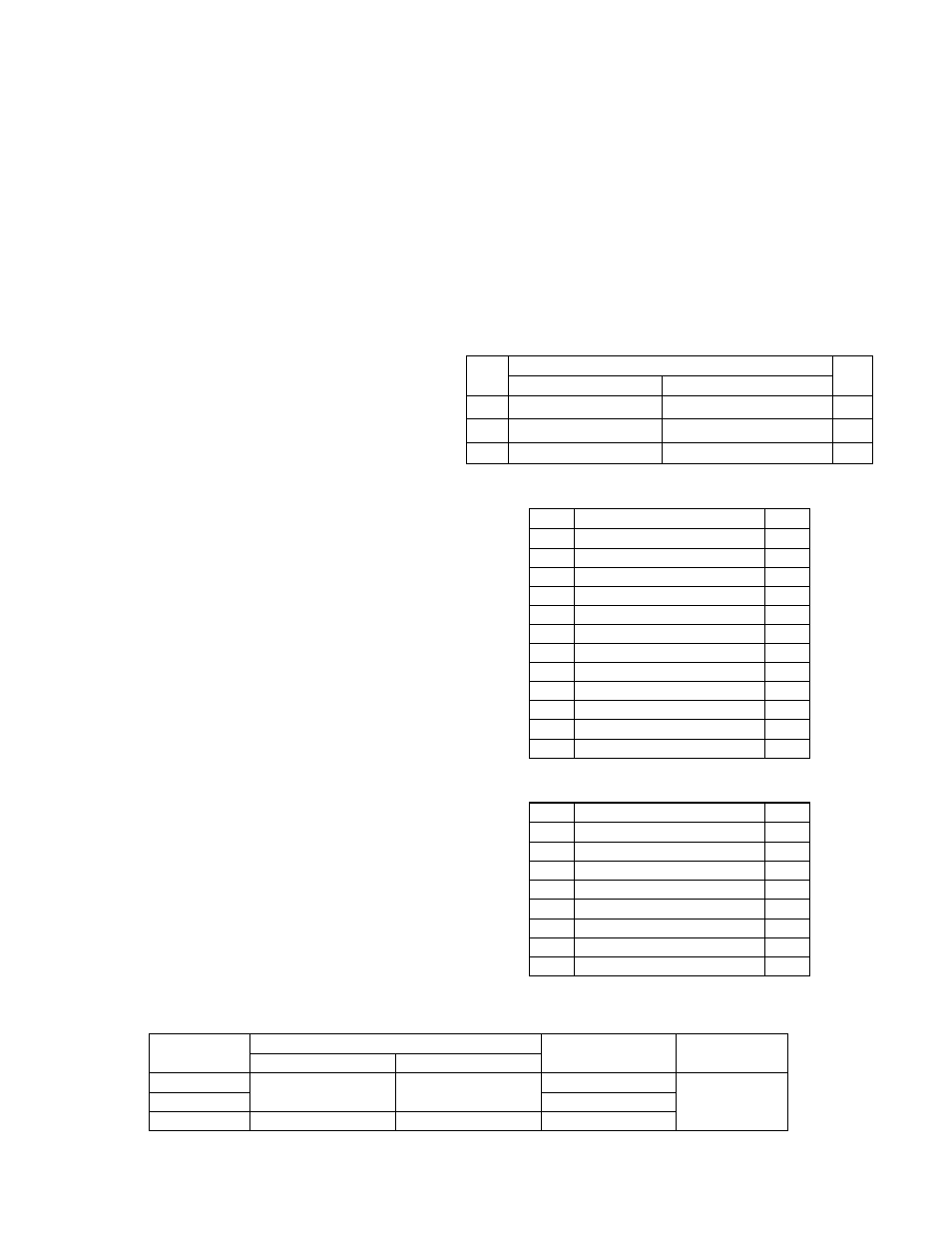

supplied, as listed in Table 2, Table 3, and Table 4.

Note that the numbers in brackets in the following

figures and installation instructions refer to the

item numbers in these tables.

GE Cable Operating Mechanisms, illustrated in

Figure 1, are suitable for application with GE

circuit breakers mounted in a wide variety of

flanged enclosure types and sizes. The catalog

numbers and appropriate applications for the

available handle operating mechanisms, breaker

operating mechanisms, and cables are listed in

Table 1.

Check Table 4 to verify that the handle assembly,

cable, and breaker operating mechanism you have

are correct for the job. Check Figure 2 and Table 5

to ensure that the cable is long enough to reach

the breaker and that the 3-inch minimum bending

radius requirement is not violated.

Flange-mounted handle assemblies are available

for NEMA Type 1, 3R, 12, or 13 enclosures in either

6-inch (model FCNHM1) or 10-inch handle

lengths (model FCNHM2). Corresponding

assemblies, FCNHM3 and FCNHM4, are available

for NEMA Type 4/4X enclosures. Handle

assemblies are suitable for either left- or right-

flange operation.

Description

Item

QTY

FCNBM FENBM

1 Mechanism

Mechanism

1

The handle assembly is combined with one of

eight operating cables, with lengths from 3 to 10

feet, to cover a broad range of breaker mounting

locations in the enclosure. The cable links the

handle assembly to the breaker-mounted operating

mechanism and transmits the mechanical force

and motion of the handle mechanism to the

breaker-mounted mechanism. The force and

motion are transmitted independent of the breaker

mounting plane or location relative to the location

of the handle assembly, provided only that the

bending radius of the cable is no less than 3 inches.

No mounting reinforcement of the breaker or

enclosure flange is required.

Screw,

#10-32 X 3.15"

2

Screw, #8-32 x 2.81"

4

Screw, #10-32 x 0.50"

3

Screw, #8-32 x 0.312"

4

Table 2. Parts included in the breaker operating mechanism kits.

Item Description Qty.

4 Handle

assembly

1

5 O-ring

1

6 Cable

adapter

assembly

1

7 Screw,

1

/

4

-20 x

5

/

8

" 2

8 Lock

washer,

1

/

4

" 2

9 Interlock

blade

1

SEMS screws, #8-32 x

3

/

8

"

10

6

The breaker operating mechanism mounts directly

to the face of the breaker and does not involve any

mounting interface with the enclosure. Standard

breaker mounting screws for tapped holes are

furnished with each mechanism to mount the

breaker in the enclosure.

11 Connecting

pin

1

12 Retaining

ring

1

13 Spring

1

14 Interlock

bracket

1

15 Interlock

hook

1

Installation of the handle assembly onto the

enclosure flange can be performed independently

from installation of the breaker operating

mechanism onto the circuit breaker and from

installation of the circuit breaker in the enclosure.

First, install the breaker into the enclosure, and

then mount the breaker operating mechanism on

the breaker and the handle operating mechanism

to the enclosure. Install the cable between the

handle assembly and the breaker mechanism as

the final step.

Table 3. Parts included in the handle mechanism kits.

Item Description Qty.

16 Cable

assembly

1

17 Hex

nut,

7

/

16

-20 2

18 Lock

washer,

7

/

16

" 2

19 Cable guide pin

1

20 Retaining

ring

1

21 Hex nut, #10-32

2

22 Spring

1

23 Spring

retainer

1

Table 4. Parts included in the cable kits.

Handle Operating Mechanism

Circuit

Breaker Type

Breaker Operating

Mechanism

Operating

Cable

NEMA 1, 3R, 12, 13

NEMA 4/4X

FC100 FCNBM

FCNHM1 FCNHM3

FE250

FENBM

SC3L to SC10L

FG600 FCNHM2 FCNHM4 FGNBM

Table 1. Catalog numbers of the cable operating mechanism components covered by these instructions.