Thermal considerations, Continued) – GE Industrial Solutions ESTW010A0A Series User Manual

Page 10

Data Sheet

November 29, 2011

ESTW010A0A Series Eighth-Brick Power Modules

36

–75Vdc Input; 5.0Vdc Output; 10A Output Current

LINEAGE

POWER

10

Thermal Considerations

(continued)

OU

TP

U

T

C

U

R

R

E

N

T

,

I

O

(

A

)

AMBIENT TEMEPERATURE, T

A

(

o

C

)

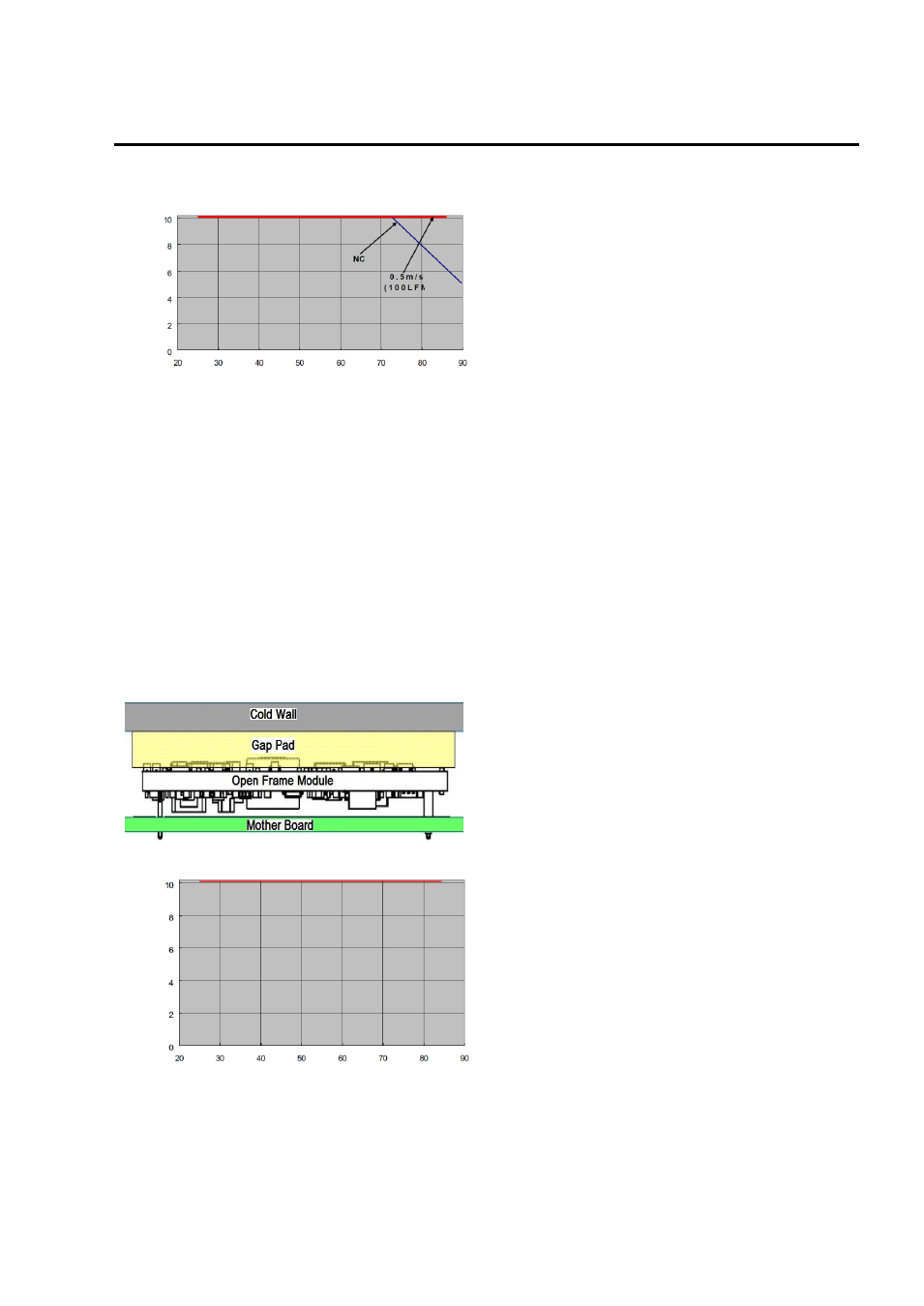

Figure 18. Output Current Derating for the Module

with Heatplate with Heatplate

and 0.50” Heatsink;

Airflow in the Transverse Direction from Vout(+) to

Vout(-); Vin =48V.

Heat Transfer via Conduction

The module can also be used in a sealed environment

with cooling via conduction from the

module’s top

surface through a gap pad material to a cold wall, as

shown in Figure 19. This capability is achieved by

insuring the top side component skyline profile

achieves no more than 1mm height difference

between the tallest and the shortest power train part

that benefits from contact with the gap pad material.

The output current derating versus cold wall

temperature, when using a gap pad such as Bergquist

GP2500S20, is shown in Figure 20.

Figure 19. Cold Wall Mounting

OU

TP

U

T

C

U

R

R

E

N

T

,

I

O

(

A

)

COLDPLATE TEMEPERATURE, T

C

(

o

C)

Figure 20. Derated Output Current versus Cold

Wall Temperature with local ambient temperature

around module at 85C; Vin=48V.