GE Industrial Solutions Power Break II Motor Operator User Manual

Page 3

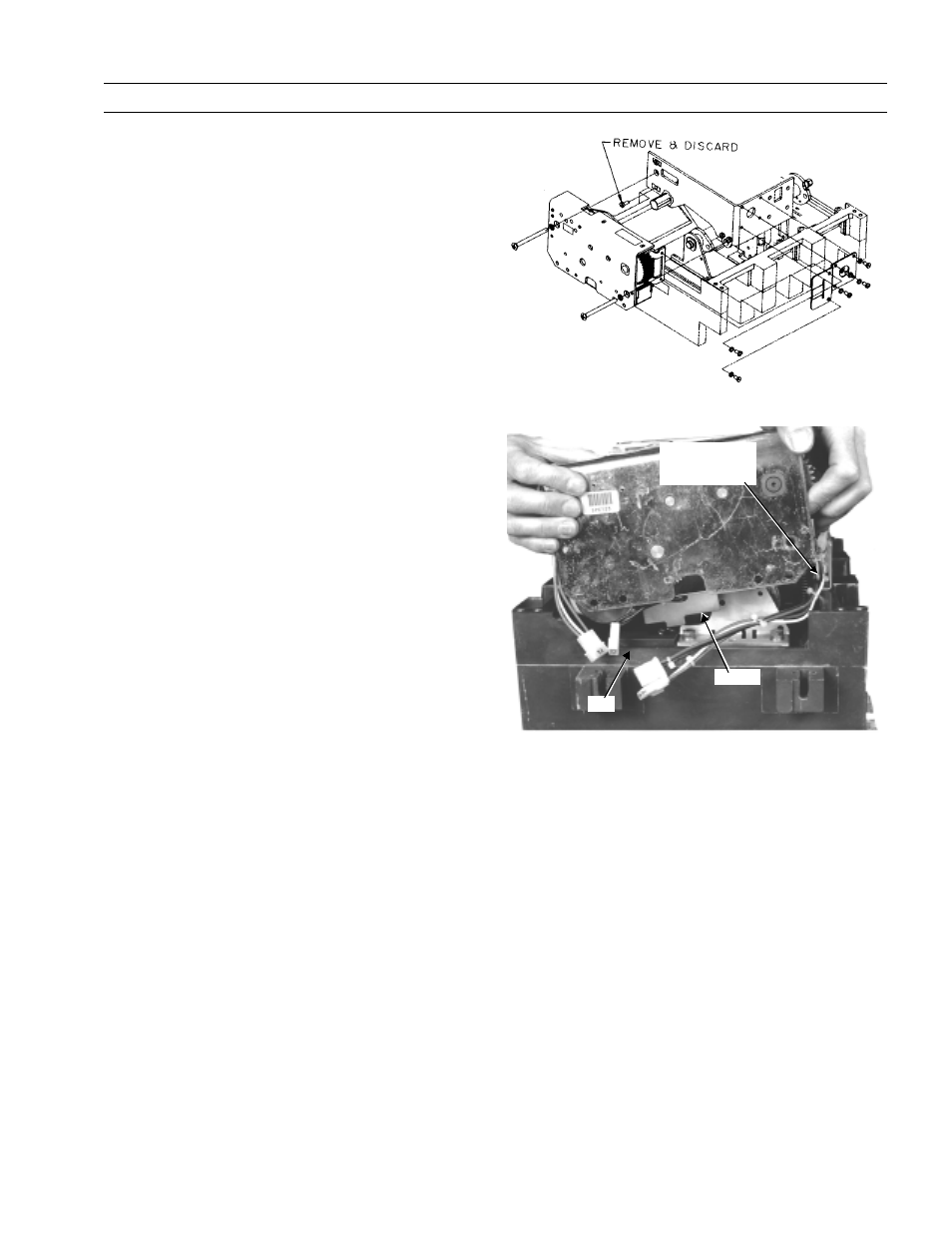

Power Break® II Motor Operator Mechanism

Installation in 800–4000 A Stationary Breaker

3

onto the breaker until the spacers engage the

spring frame and the stop block.

1

1

1

1 2

2

2

2 .... Attach the Mounting Bracket to the four holes

opposite the stop block on the spring frame with

#10-32 screws tightened to 32 in-lb torque. The

bend of the bracket must be outward from the

spring frame.

1

1

1

1 3

3

3

3 .... Align the two holes in the Mounting Bracket with

the two holes in the Motor Operator Mechanism

and attach with two #10-32 screws tightened to 32

in-lb torque.

1

1

1

1 4

4

4

4 .... Thread a

1

⁄

4

–20 flat-head screw and conical lock

washer through the spacer and into the stop block,

as illustrated in Figure 4. Thread the other

1

⁄

4

–20

flat-head screw and conical lock washer through

the spacer into the captive nut in the spring frame.

Tighten both screws to 70 in-lb.

1

1

1

1 5

5

5

5 .... Plug the color-coded, numbered Motor Operator

Mechanism wires into the corresponding num-

bered sockets, as illustrated in Figure 6. Mating

connector wires are installed at the factory and are

located in the gray-painted channel, shown in

Figure 5

1

1

1

1 6

6

6

6 .... Dress the wires and install cable ties as shown in

the illustration in Figure 7. Ensure that wires are

clear of all moving parts.

1

1

1

1 7

7

7

7 .... Reinstall the secondary terminal block onto the

breaker midcover terminal block mounting ridge

and fasten with the screw previously removed.

1

1

1

1 8

8

8

8 .... Crank the operating handle once and hold the

handle extended to reinstall the breaker top cover.

Tighten the four #10-32 mounting screws to 15 in-

lb.

1

1

1

1 9

9

9

9 .... Replace the trim plate and tighten the four #8-32

screws to 20 in-lb.

2

2

2

2 0

0

0

0 .... Affix the accessory rating label to the breaker cover

above the right-side secondary terminal block.

2

2

2

2 1

1

1

1 .... Affix the “Electrically Operated” label to the top

cover over the knock-out space above the ON-OFF

indicator flag.

2

2

2

2 2

2

2

2 .... Crank the operating handle until the closing

springs are completely charged.

2

2

2

2 3

3

3

3 .... Close and trip the breaker.

2

2

2

2 4

4

4

4 .... Test the Motor Operator Mechanism electrically

according to Table 1.

Figure 4. Installing the Motor Operator Mechanism onto the breaker.

Figure 5. Rotating the Motor Operator Mechanism so that the guard

clears the lip on the side of the circuit breaker.

Motor Operator

Wires in Gray

Channel

Guard

Lip