Data sheet, Feature descriptions (continued) – GE Industrial Solutions EBVW020A0B Barracuda Series User Manual

Page 10

GE

Data Sheet

EBVW020A0B Barracuda Series; DC-DC Converter Power Modules

36-75Vdc Input; 12.0Vdc, 20.0A, 240W Output

July 22, 2013

©2012 General Electric Company. All rights reserved.

Page 10

Feature Descriptions (continued)

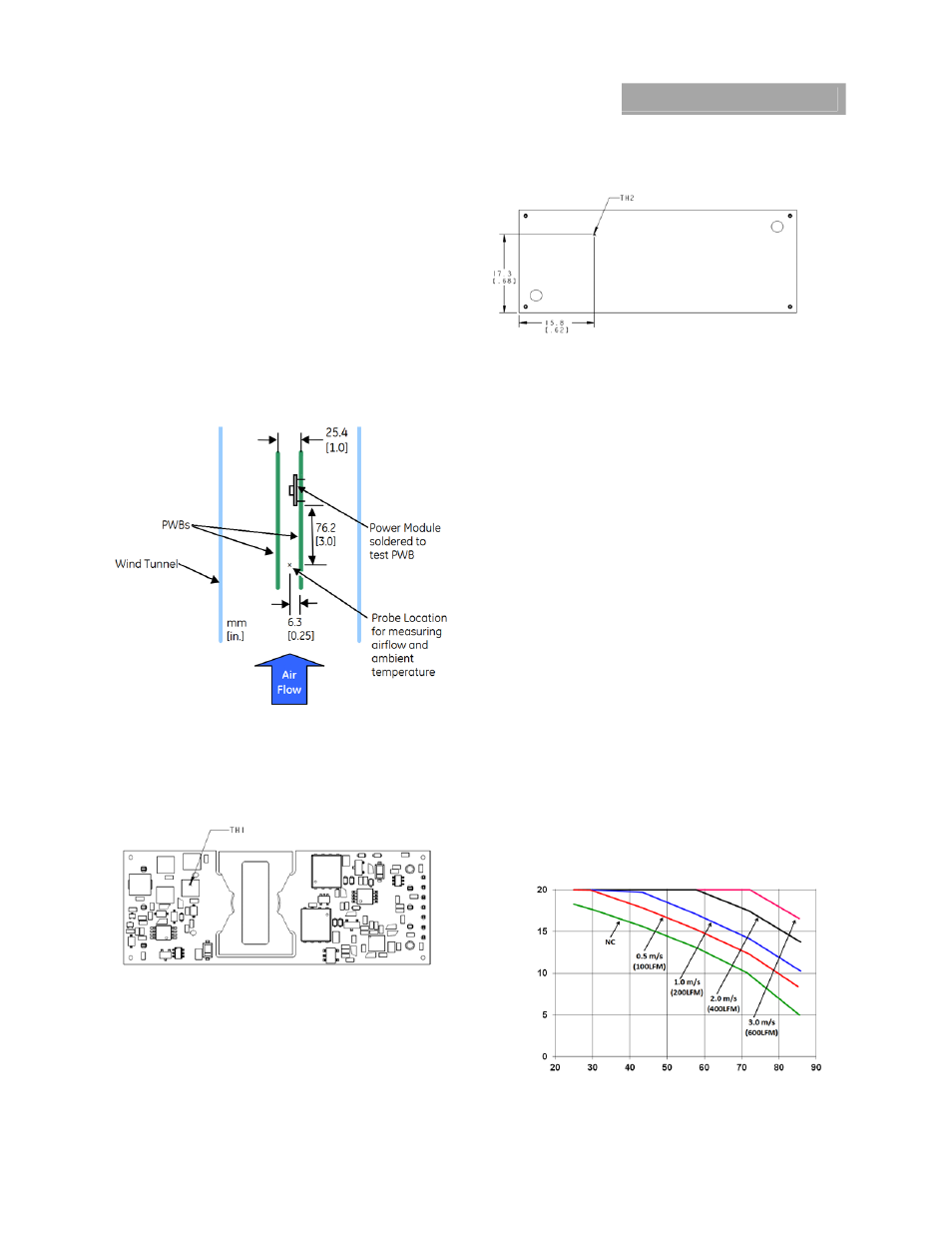

The thermal data presented here is based on physical

measurements taken in a wind tunnel, using automated

thermo-couple instrumentation to monitor key component

temperatures: FETs, diodes, control ICs, magnetic cores,

ceramic capacitors, opto-isolators, and module pwb

conductors, while controlling the ambient airflow rate and

temperature. For a given airflow and ambient temperature, the

module output power is increased, until one (or more) of the

components reaches its maximum derated operating

temperature, as defined in IPC-9592. This procedure is then

repeated for a different airflow or ambient temperature until a

family of module output derating curves is obtained.

Heat-dissipating components are mounted on the top side of

the module. Heat is removed by conduction, convection and

radiation to the surrounding environment. Proper cooling can

be verified by measuring the thermal reference

temperature

(TH

x

). Peak temperature (TH

x

) occurs at the position indicated in

Figure 18 and 19. For reliable operation this temperature should

not exceed the listed temperature threshold.

Figure 18. Location of the thermal reference temperature

TH

1

. Do not exceed 113 °C.

Figure 19. Location of the thermal reference temperature TH

2

for Base Plate module. Do not exceed 110 °C.

The output power of the module should not exceed the rated

power for the module as listed in the Ordering Information

table.

Although the maximum temperature of the power modules is

TH

x

, you can limit this temperature to a lower value for

extremely high reliability.

Please refer to the Application Note “Thermal Characterization

Process For Open-Frame Board-Mounted Power Modules” for a

detailed discussion of thermal aspects including maximum

device temperatures.

Heat Transfer via Convection

Increased airflow over the module enhances the heat transfer

via convection. The thermal derating of figures 20 through 22

show the maximum output current that can be delivered by

each module in the indicated orientation without exceeding the

maximum TH

x

temperature versus local ambient temperature

(T

A

) for air flows of, Natural Convection, 1 m/s (200 ft./min), 2

m/s (400 ft./min).

The use of Figures 20 is shown in the following example:

Example

What is the minimum airflow necessary for a EBVW020A0B

operating at V

I

= 48 V, an output current of 14A, and a

maximum ambient temperature of 70 °C in transverse

orientation.

Solution:

Given: V

in

= 48V, I

O

= 14A, T

A

= 70 °C

Determine required airflow (V) (Use Figure 20):

V = 200LFM or greater.

OUTP

U

T CU

RR

EN

T, I

O

(A

)

LOCAL AMBIENT TEMPERATURE, T

A

(C)

Figure 20. Output Current Derating for the Open Frame

EBVW020A0B in the Transverse Orientation; Airflow

Direction from Vin(-) to Vin(+); Vin = 48V.