Key features, Economical designs, Higher conductivity limits – GE P&W Ultrapure and Drinking Water TOC Analyzers - Sievers 500 RLe Brochure User Manual

Page 3: References, The 500 rl, Comes in two models to meet your needs. the 500 rl

Key Features

Economical Designs

The 500 RL

e

comes in two models to meet your needs. The

500 RL

e

with Standard iOS (Integrated On-Line Sampling

System) utilizes the familiar Sievers sample inlet device,

allowing for on-site calibration and running standards

and grab samples. The 500 RL

e

Base Model utilizes a

simplified sample inlet block, facilitating continuous on-

line operation. On-site calibration may be performed

using an optional iOS accessory. The 500 RL

e

Base Model

is cost-competitive with even the simplest TOC sensors,

while still providing superior analytical performance and

optional on-site calibration.

Higher Conductivity Limits

The 500 RL

e

incorporates design elements from the

Sievers 800 and 900 Series that enable reagentless

TOC measurement in waters up to 25 μS/cm at neutral

pH. Equally as important, this design enhancement

means that upsets and abnormal fluctuations in UPW

system conductivity from plant transients do not affect

analytical performance.

Sensitivity, Accuracy, Instrument-to-Instrument

Matching, and Stability

With microelectronic TOC limits being driven ever lower,

it is critical that TOC analyzers operate accurately

and reliably at sub-ppb levels. The 500 RL

e

achieves

the lowest detection limit of any TOC analyzer on the

market — 0.03 ppb — and provides the confidence

that all organics are being fully recovered regardless

of chemical composition. The automated advanced

TOC zero function provides world class Instrument-

to-Instrument matching of ± 0.05 ppb C, allowing you

to compare critical differences between water loops

at your site or on the other side of the world. The

combination of analytical sensitivity, Instrument-to-

Instrument matching, robustness, and stable sub-ppb

performance provides confidence that critical UPW

and fabrication processes are controllable and that

even the most subtle trends can be closely monitored

to protect your manufacturing processes.

References

1

Godec, Richard D., “Monitoring and Controlling UPW Organic Nitrogen Con-

tamination to Improve Immersion Photolithography Process Control.” Presented

at ULTRAPURE WATER Conference, Portland, OR, November 2011, Tall Oaks

Publishing, Inc.

2

Godec, Richard D., ”The Performance Comparison of Ultrapure Water TOC

Analyzers using an Automated Standard Addition Apparatus.” Published and

copyrighted by Semiconductor Pure Water and Chemical Conference, 2000

Proceedings.

3

Kauffman, Jon S.,Ph.D., “Validating On-Line TOC Analyzers for Real-Time

Release.” Pharmaceutical Manufacturing, Nov/Dec 2006.

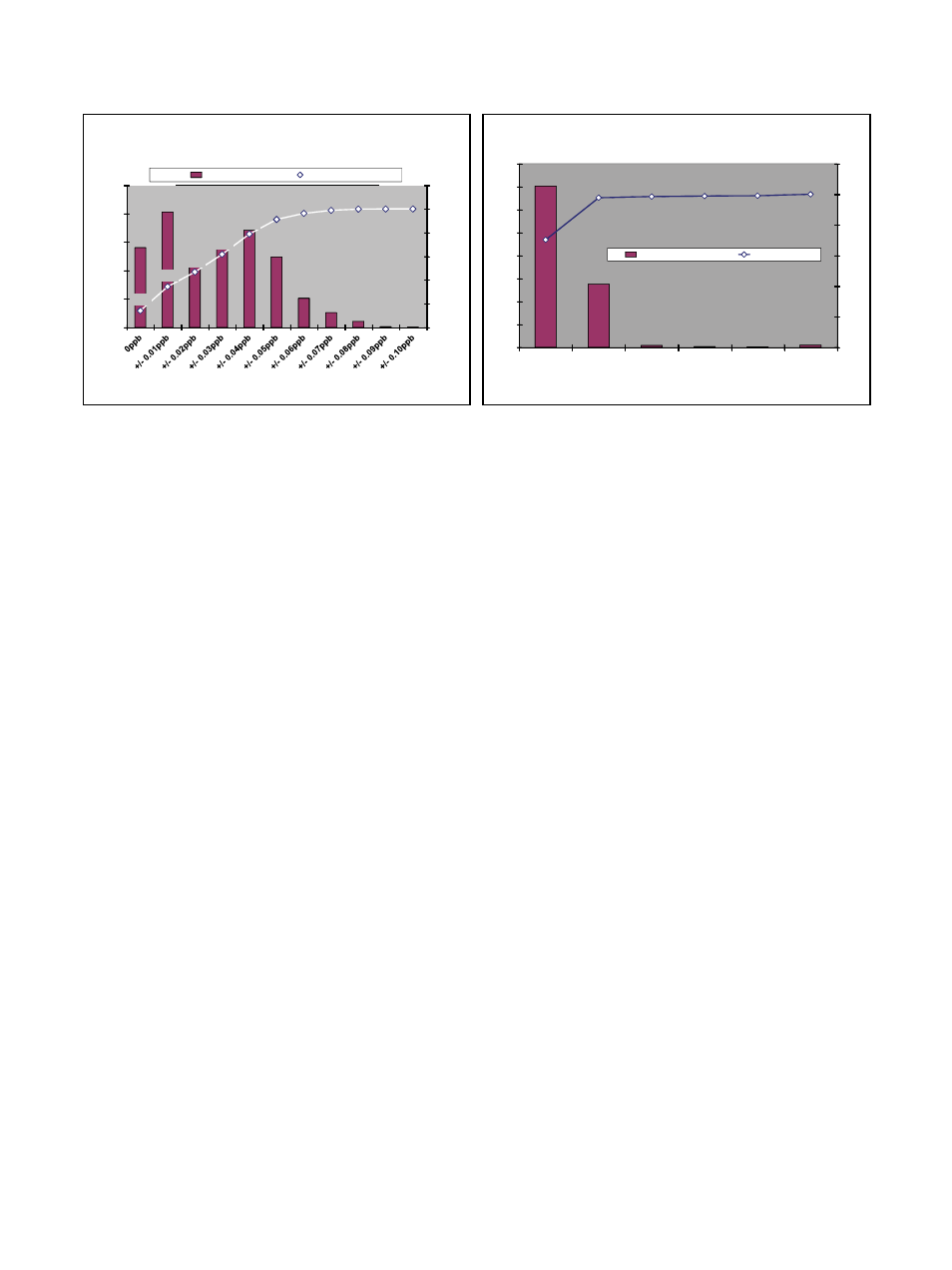

Figure 3. Instrument-to-Instrument study results proving the

± 0.05 ppb C match between five analyzers

Figure 4. LOD study results proving the 0.03 limit of detection

for multiple 500 RL

e

Analyzers

14%

34%

47%

62%

79%

91%

96% 99% 100% 100% 100%

0%

20%

40%

60%

80%

100%

120%

0%

5%

10%

15%

20%

25%

C

um

ul

at

iv

e

%

%

o

f T

ot

al

R

ea

di

ng

s

Instrument-to-Instrument Matching (ppb C)

91% of Measurements are within

± 0.05 ppb C

5 Separate 500 RLe On-line TOC Analyzers

- Matching on Same 0.3 ppb C UPW

Data Collected for 2 Months n = 155,925 data points

Difference

Cumulative

70%

98%

99%

99%

99%

100%

0%

20%

40%

60%

80%

100%

120%

0%

10%

20%

30%

40%

50%

60%

70%

80%

0-0.01

0.01-0.02 0.02-0.03 0.03-0.04 0.04-0.05

> 0.05

LOD (ppb C)

98% of LODs are Less that 0.02 ppb C

Five Each On-line 500 RLe TOC Analyzers- Same UPW- 32 Days

LODs Calculated Using a 10 PT Moving Average N = 44,272 Separate LOD Analyses

Percent of values

Cumulative