Robust method, Low do / hydrogenated water applications, Toc recovery – GE P&W Ultrapure and Drinking Water TOC Analyzers - Sievers 500 RLe Brochure User Manual

Page 2: Risk of simplified toc methods, The 500 rl, 2 ppb

affecting the lithography or another critical process.

Because you are measuring all the organics with the

500 RL

e

, your facilities engineers are given the best tool

to optimize their processes. The top semiconductor

companies in the world accept no other options for

their critical UPW TOC measurements.

Low DO / Hydrogenated Water Applications

Low DO and hydrogenated water systems are becoming

more common in microelectronics applications. Low DO

systems present a significant challenge to reagentless

TOC analyzers because all reagentless TOC analyzers

rely on the process water as a source of oxygen for fully

oxidizing the organics in the sample.

In low DO systems, there is insufficient oxygen available

to facilitate full oxidation, resulting in artificially low TOC

results. If a contamination event occurs, the lack of

oxygen may prevent complete oxidation of the organics.

Consequently, most analyzers will show little or no change

in the TOC value. Only the Sievers 500 RL

e

incorporates

trace oxygen addition to ensure fully oxidized organics in

low DO and hydrogenated water systems. This gives you

the ability to see important changes in your water system

that other analyzers completely miss (see Figure 2).

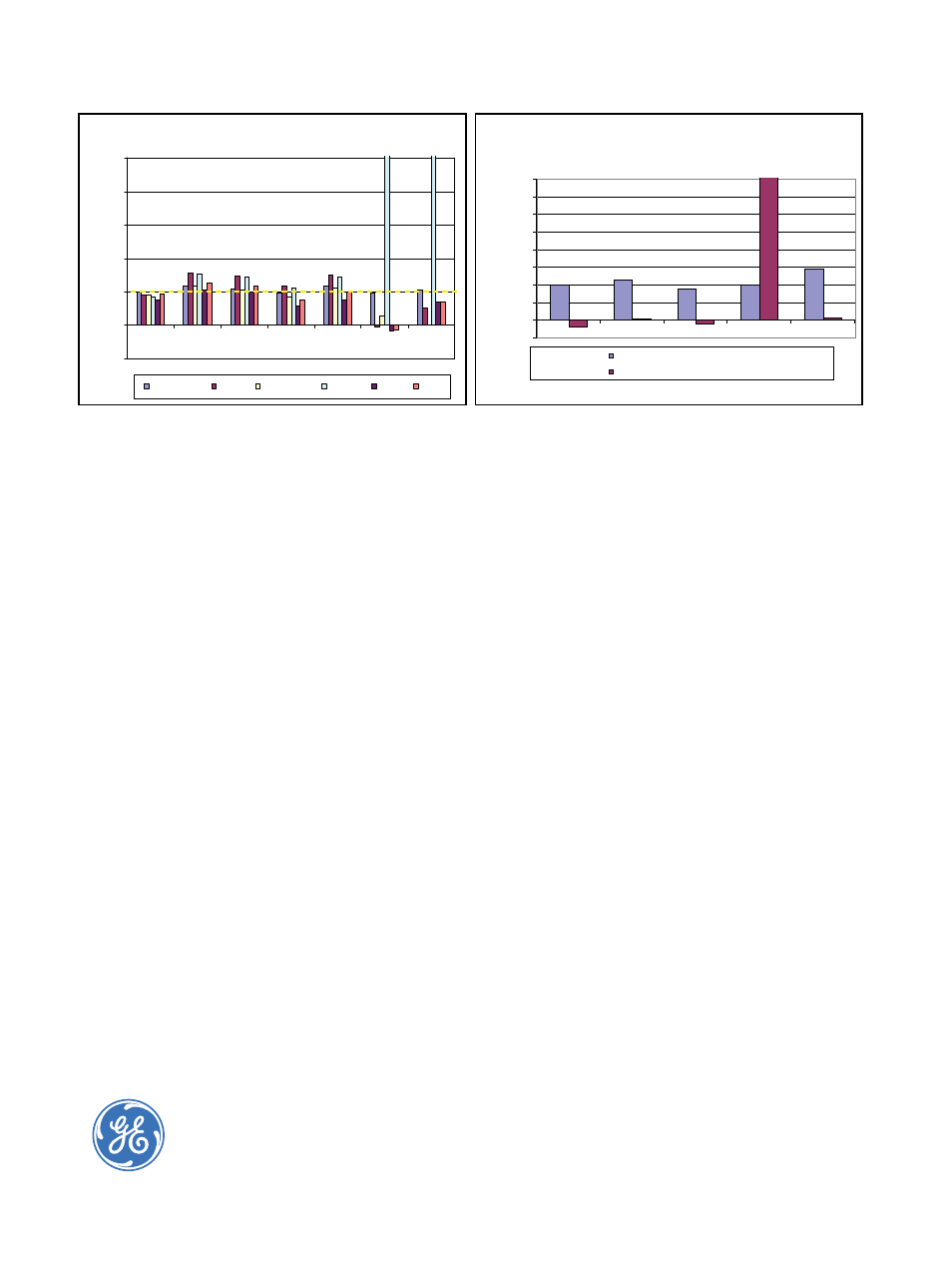

Robust Method

TOC Recovery

The 500 RL

e

has been extensively tested to demonstrate

comparability to the Sievers PPT Analyzer as well as

superior performance relative to competitive TOC

technologies.

1,2,3

Figures 1 and 2 show the performance

of the 500 RL

e

in normal and Low DO systems, compared

to the PPT and alternative TOC technologies.

Risk of Simplified TOC Methods

Can you trust the TOC results from your analyzer

to provide your fabrication engineers with the best

measurement tools? Simplified TOC methods used in

other TOC analyzers expose the water system and fab

to contamination risks from compounds that these

simplified technologies can not detect. In numerous

published studies and technical papers,

1,2,3

these

simplified TOC analyzers have been demonstrated

to be incapable of reliable performance in waters

containing even the simplest organic compounds —

compounds known to exist in UPW systems, introduced

through the feed waters, resins, system materials,

and production processes. The Sievers membrane

technology dramatically enhances the ability to detect

and manage variations in TOC contamination that

can go unnoticed and uncontrolled with older, more

simplified TOC sensors.

Figure 1. Recovery comparison of Sievers and other brands

Figure 2. Recovery graph for TOC injections

% Recovery for 5 ppb TOC Injections

-100

0

100

200

300

400

500

900

500-24

500-19

PPT-6

PPT-9

A-1000

5000TOC

%

R

ec

ov

er

y

2-Propanol

Urea

Acetic Acid

CHCl3

TMA

TMAH

% Recovery on 5 ppb Injections - Dissolved O

2

< 2 ppb

-50

0

50

100

150

200

250

300

350

400

TMA

2-Propanol

Acetic Acid

Chloroform

Urea

%

R

ec

ov

er

y

Sievers (Membrane Conductometric)

Competition (Direct Conductometric)

% Recovery for 5 ppb TOC Injections

% Recovery on 5 ppb Injections - Dissolved O

2

< 2 ppb